Sliding rail type supporting beam of warehouse

A support beam and slide rail type technology, applied in the field of support beam structure, can solve the problems of inconvenient installation and inconvenient position adjustment, and achieve the effect of convenient position adjustment and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

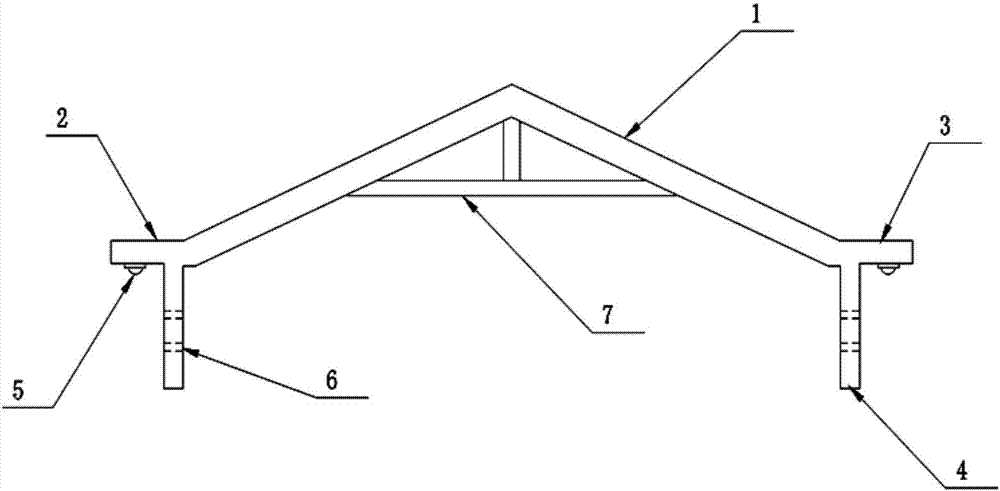

[0025] refer to Figure 1 ~ Figure 3 , the present invention provides a warehouse slide rail type support beam, comprising: a support beam body 1, the two ends of the support beam body 1 are welded with an L-shaped bracket 2 for fixing on an external beam, and the L-shaped bracket 2 includes a first branch The rod 3 and the second pole 4, the roller 5 is installed under the first pole 3, the second pole 4 is provided with a bolt hole 6 for fixing, and the support beam body 1 is connected with a reinforcement bracket 7. When installing, place the L-shaped brackets 2 at both ends on the external beam, and the roller 5 directly contacts and slides with the beam, adjusts the position of the support beam forward and backward, and then fixes and connects with the external beam by installing fixing bolts in the bolt holes 6. The structure is simple , Easy to adjust the position.

[0026] In this embodiment, the rollers of the warehouse slide rail type support beam directly contact a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com