Moisture-absorbing quick-drying type jacquard fabric as well as hydrophilic quick-drying finishing agent and post processing method thereof

A jacquard fabric, moisture-absorbing and quick-drying technology, applied in the treatment of textile materials, liquid/gas/steam textile material processing, fabrics, etc. Reduced durability and other issues, to achieve the effect of cleaner production, environmental protection, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

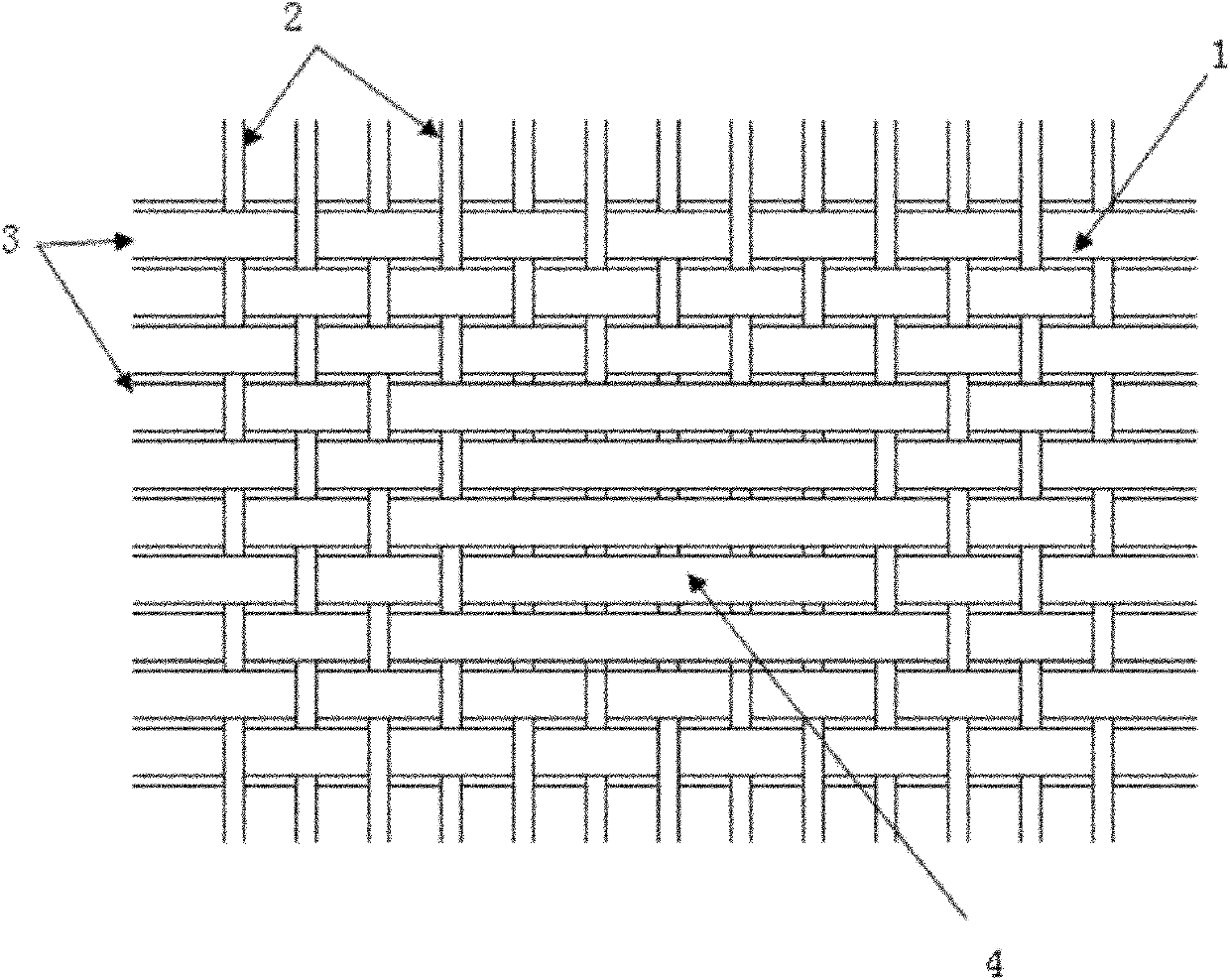

[0026] Warp 2 is Modified nylon, the weft yarn 3 is a fine-denier cross-section polypropylene, and its base fabric area 1 is formed by interlacing the warp yarn 2 and the weft yarn 3, which is a plain weave structure. 4 yarns, the density ratio of warp and weft yarns is 1:1.10, the linear density of weft yarns is 1 / 75D / 72f, and the monofilament fineness is 1.04D. The standard moisture regain of modified nylon is 5.4%, the linear density is 1 / 75D / 72f, the warp and weft density of the base fabric is 480×530 threads / 10cm, and the square meter weight is 91g / m 2 .

Embodiment 2

[0028] The warp yarn 2 is modified nylon. In the jacquard area, the floating and sinking interval between the warp yarn and the weft yarn is 3 warp yarns floating and 5 weft yarns sinking. The density ratio of warp yarns to weft yarns is 1:1.2, and the warp and weft density of the base fabric is 460×550 Root / 10cm, all the other are with embodiment 1.

Embodiment 3

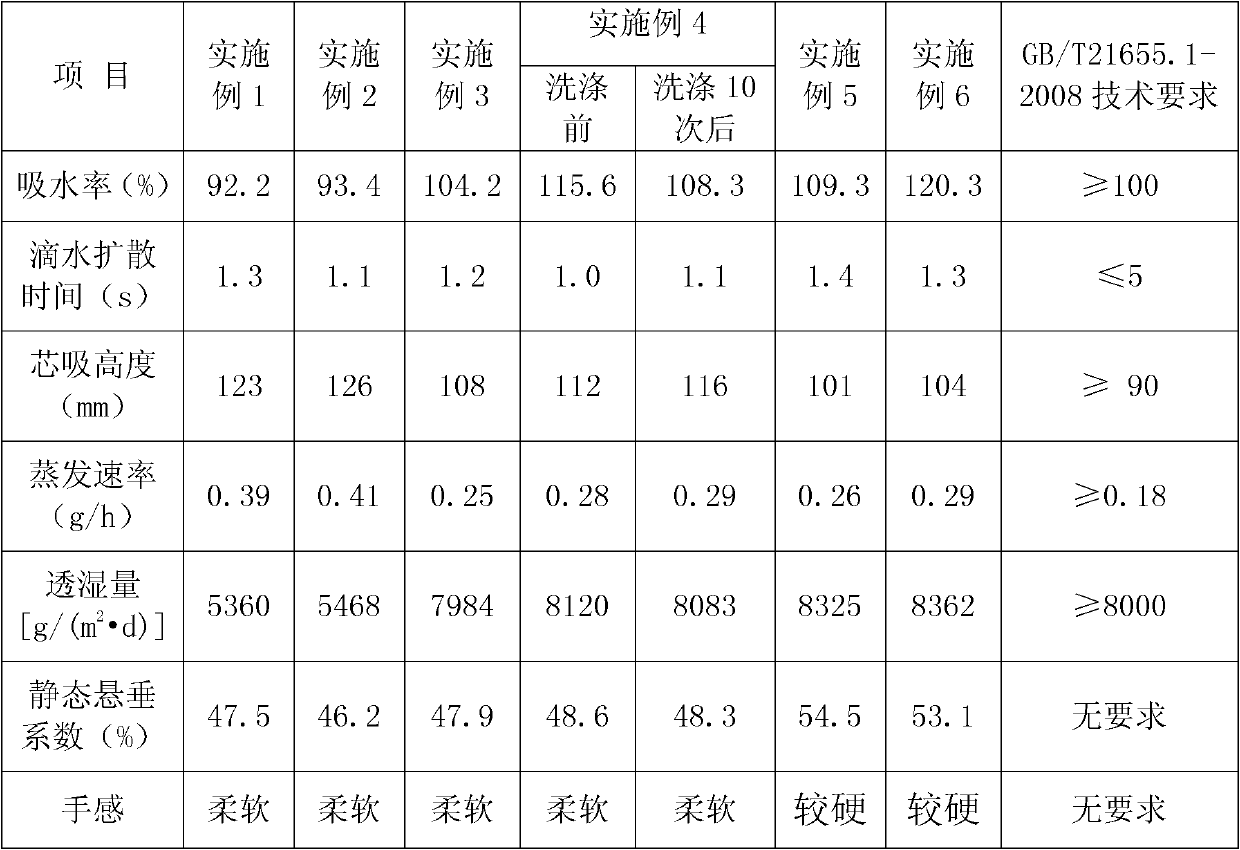

[0030]Be processed into woven fabric by embodiment 1, carry out hydrophilic quick-drying aftertreatment then. The hydrophilic quick-drying finishing agent comprises 8% of polyvinylpyrrolidone (PVP-K30) by weight; 4% of water-soluble polyurethane; and the rest is water. Hydrophilic treatment is carried out by normal temperature padding process. The running speed of the fabric is 20±1m / min; the drying temperature is 90-130°C; the baking temperature is 160°C; the fabric weight gain after finishing is 5.8%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com