C3N4-carbon-coated lithium iron phosphate composite anode material and preparation method thereof

A carbon-coated lithium iron phosphate and composite cathode material technology, which is applied to battery electrodes, electrical components, circuits, etc., can solve problems such as failure to exhibit rate and cycle performance, incomplete carbon coating, and lack of conductive network connections. Achieve the effect of improving the overall electronic conductivity, low cost, and high cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: C 3 N 4 Preparation of nanosheets

[0025] Weigh 20 grams of melamine or dicyandiamide or urea into a crucible, place it in a muffle furnace, heat it to 550°C at a rate of 2°C per minute, and keep it at 550°C for 5 hours. It was taken out and ground to give a yellow powder C 3 N 4 sample. Weigh 1 g of yellow C 3 N 4 Put the sample into a jar, add 100 ml of isopropanol, place it in an ultrasonic machine for 10 hours to form a suspension, then centrifuge the suspension at 3000 rpm for 10 minutes to remove the sediment, and then remove the upper layer The suspension was centrifuged at a high speed of 12,000 rpm to obtain a light yellow solid C 3 N 4 The nanosheets are about 0.7 grams.

Embodiment 2

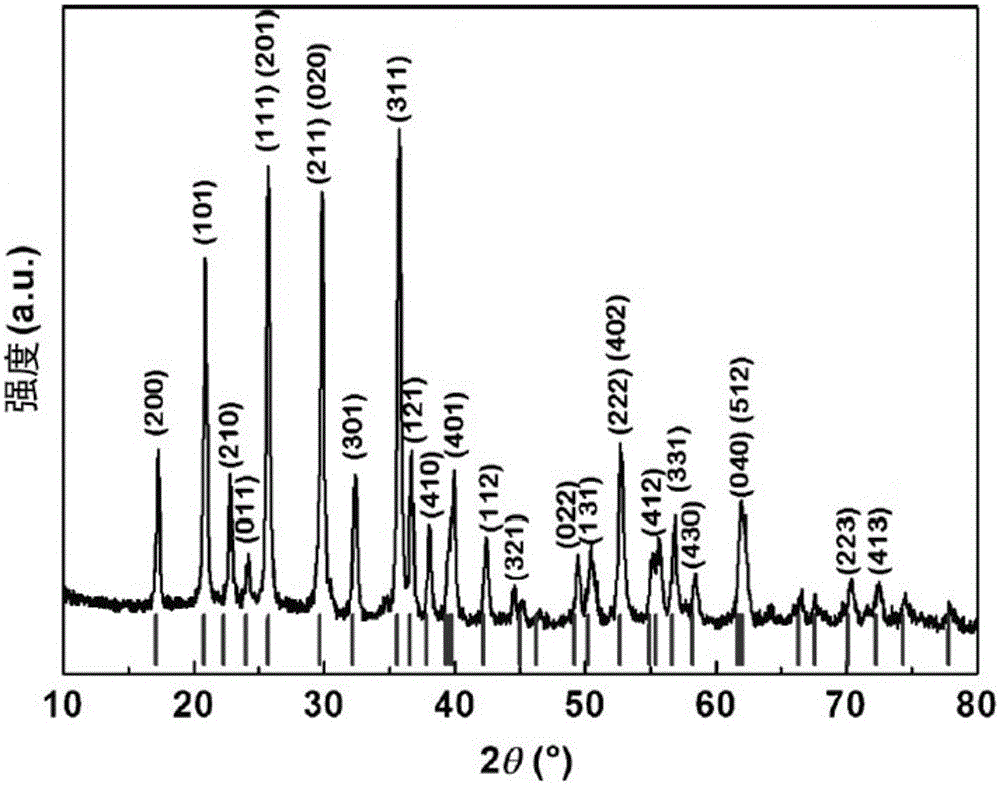

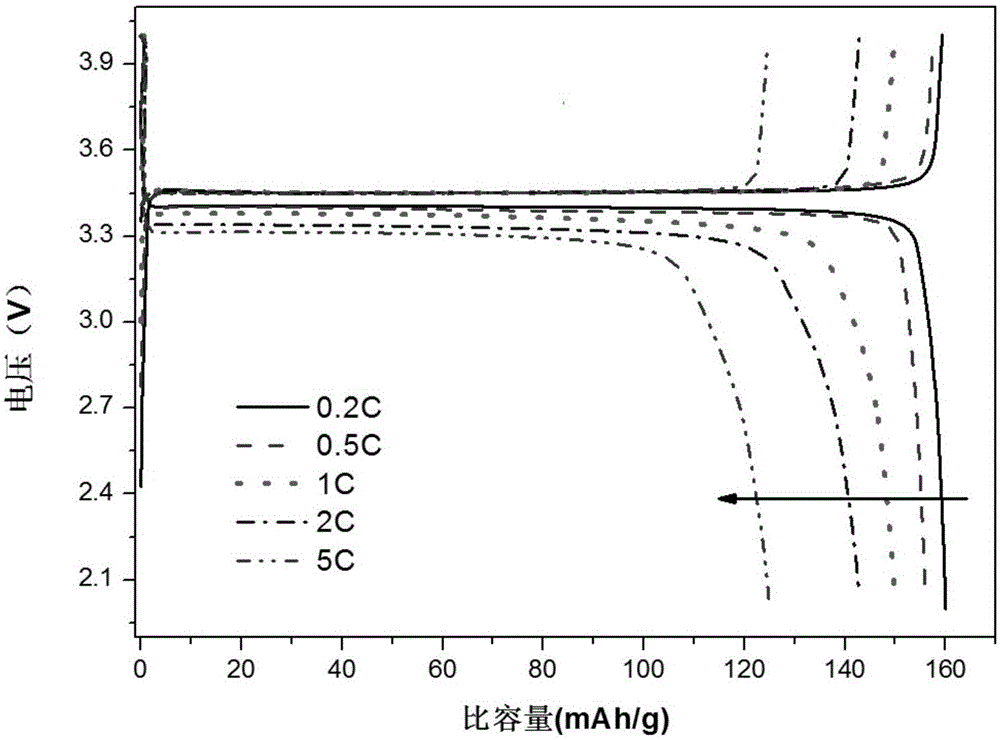

[0027] At room temperature, 0.35 g C 3 N 4 The nanosheets were dispersed in 100ml of deionized water and stirred evenly to prepare C 3 N 4 nanosheet suspension, and then 11.21 grams of FeCl 3 ·6H 2 O was added to this suspension. Then 5.48 g (NH 4 ) 2 HPO 4 The mixed solution of pyrrole monomer was slowly added to FeCl 3 / C 3 N 4 in the mixed solution. The mixed solution was stirred for 3 hours, filtered, washed with deionized water, and dried to obtain C 3 N 4 -Fe 3 PO 4 Precursor powder. Weigh 4.23 g of CH 3 COOLi·2H 2 O is dissolved in the mixed solution of ethanol and water, and C is added 3 N 4 -Fe 3 PO 4 Precursor powder and 0.5 gram of sucrose, after evaporating the solvent to dry, place in a tube furnace, and use 99% nitrogen as a protective gas, and raise the furnace temperature to 700 °C at a heating rate of 3 °C per minute, at 700 °C Insulated for 8 hours, then naturally cooled to room temperature to obtain a gray-black final product.

[0028]...

Embodiment 3

[0032] At room temperature, 0.6 g of C 3 N 4 Nanosheets were dispersed in 100ml of deionized water, stirred evenly, and then 11.21 grams of FeCl 3 ·6H 2 O join this C 3 N 4 nanosheet suspension. 5.48 g (NH 4 ) 2 HPO 4 The mixed solution of pyrrole monomer was slowly added to FeCl 3 / C 3 N 4 In the mixed solution, the mixed solution was stirred for 3 hours and then filtered, washed with deionized water, and dried to obtain C 3 N 4 -Fe 3 PO 4 Precursor powder. Weigh 4.23 g of CH 3 COOLi·2H 2 O is dissolved in the mixed solution of ethanol and water, and C is added 3 N 4 -Fe 3 PO 4 Precursor powder and 0.9 g of sucrose, after evaporating the solvent to dry, place in a tube furnace, and use 99% nitrogen as a protective gas, and raise the furnace temperature to 700 °C at a heating rate of 3 °C per minute. Insulated for 8 hours, then naturally cooled to room temperature to obtain a gray-black final product. Subsequent electrode preparation and half-cell prepara...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com