Pre-stretching base and manufacture method thereof and electron device and manufacture method thereof

A manufacturing method and technology of electronic devices, applied in the direction of electronic equipment, electrical solid devices, electrical components, etc., can solve the problems of large area and uniform pre-stretching amount of pre-stretched substrate, so as to prolong the service life, ensure uniformity, The effect of good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

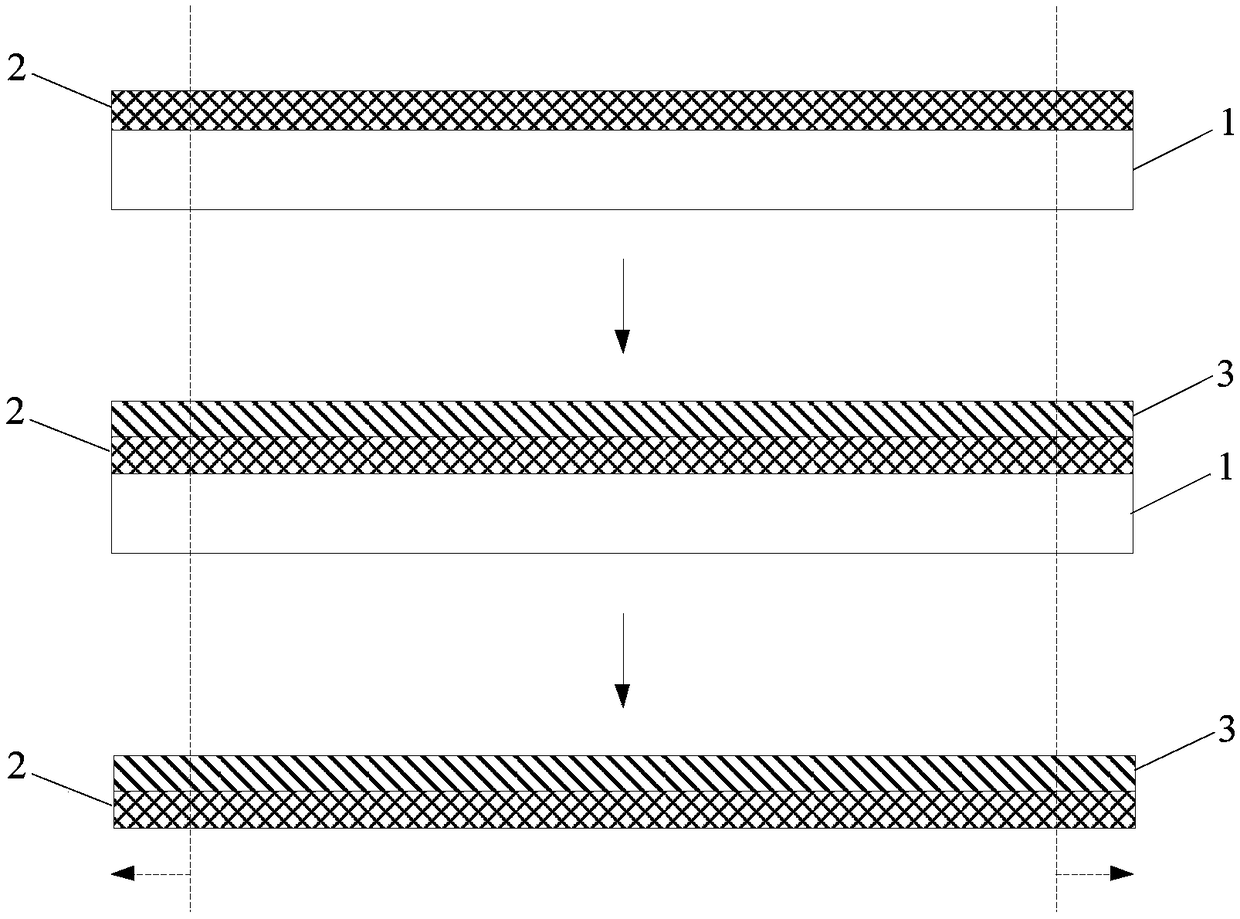

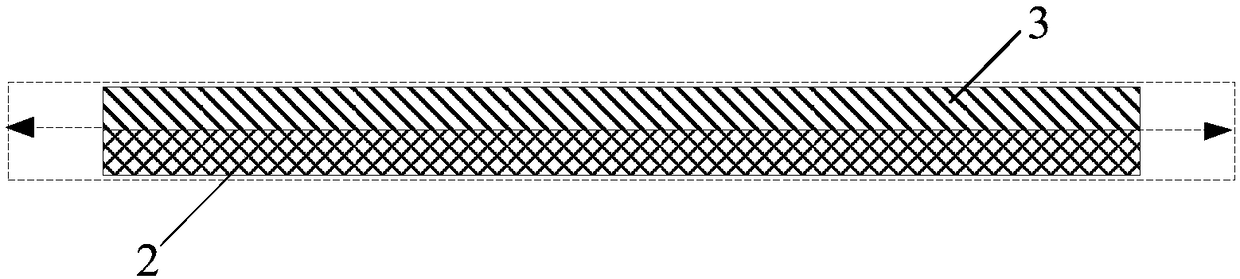

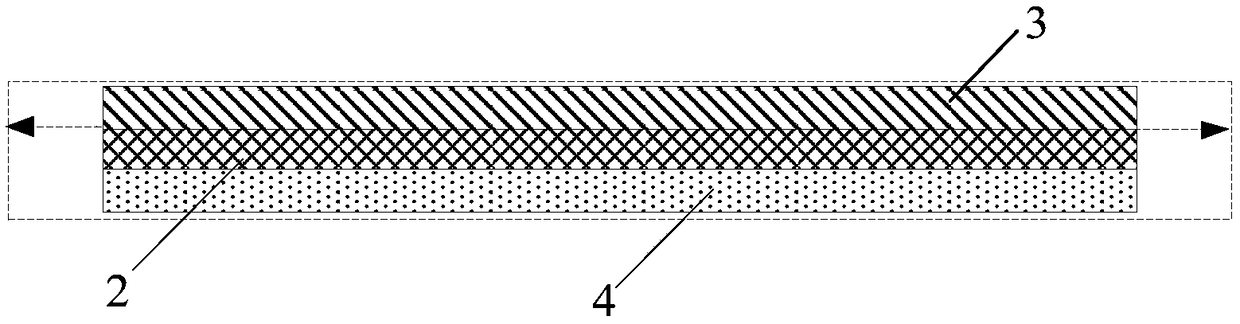

[0062] In order to further illustrate the pre-stretched substrate and its manufacturing method provided by the embodiments of the present invention, the electronic device and its manufacturing method, the detailed description will be described below in conjunction with the accompanying drawings.

[0063] The manufacturing method of the pre-stretched base provided by the embodiment of the present invention comprises:

[0064] In an environment higher than a preset temperature, at least two film layers are sequentially formed on the carrier plate, and the thermal expansion coefficients of the at least two film layers are different;

[0065] Specifically, the above-mentioned preset temperature can be selected as normal temperature, for example: 25° C., the temperature in the environment higher than the preset temperature can be set according to the thermal expansion coefficients of at least two film layers to be actually produced, for example: it can be set higher than The temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com