System for the conversion of coal to a gas of specified composition

A specific, gaseous technology for converting coal into a gas with a specific composition, which can solve problems affecting the efficiency of engine operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

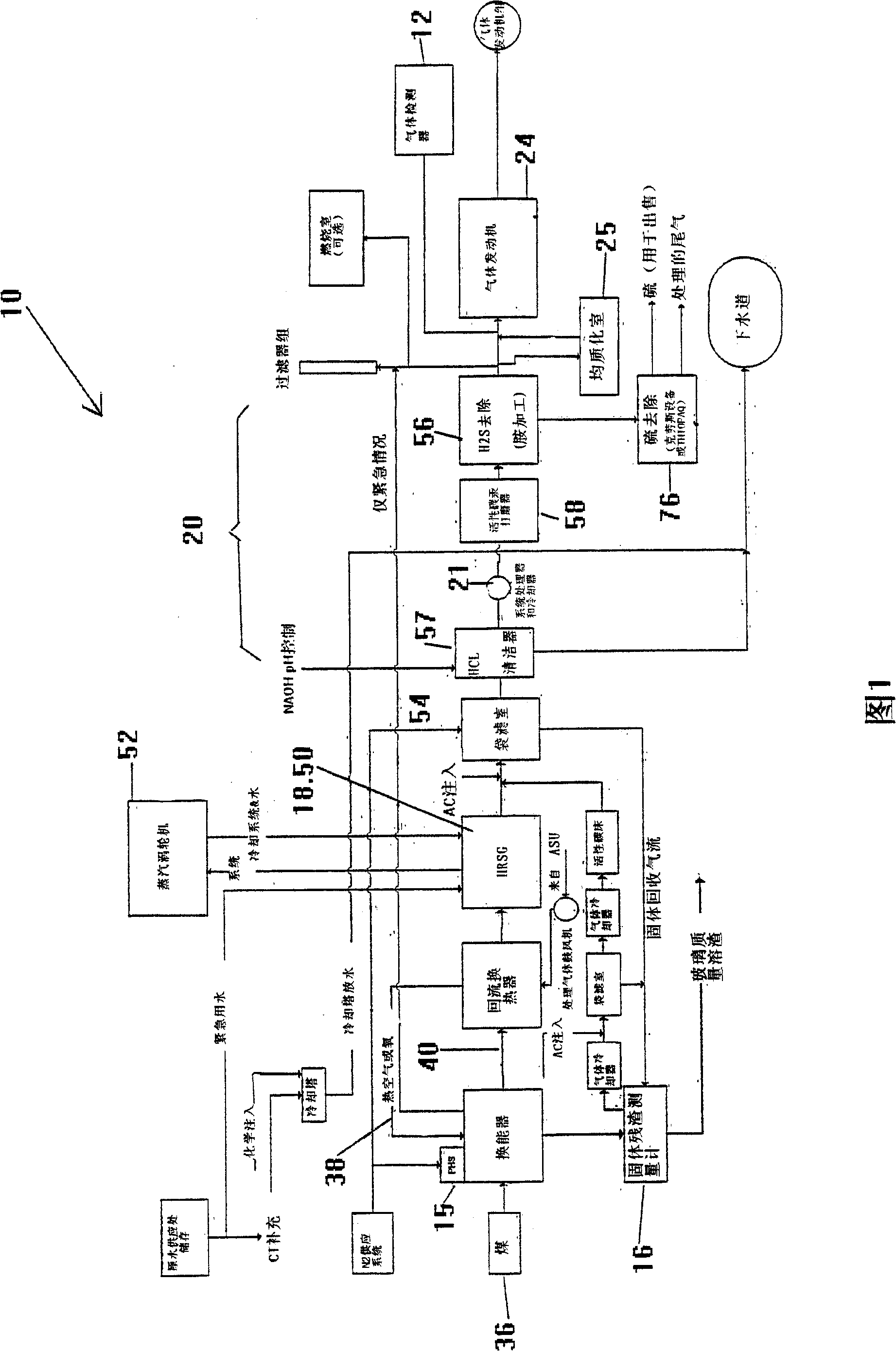

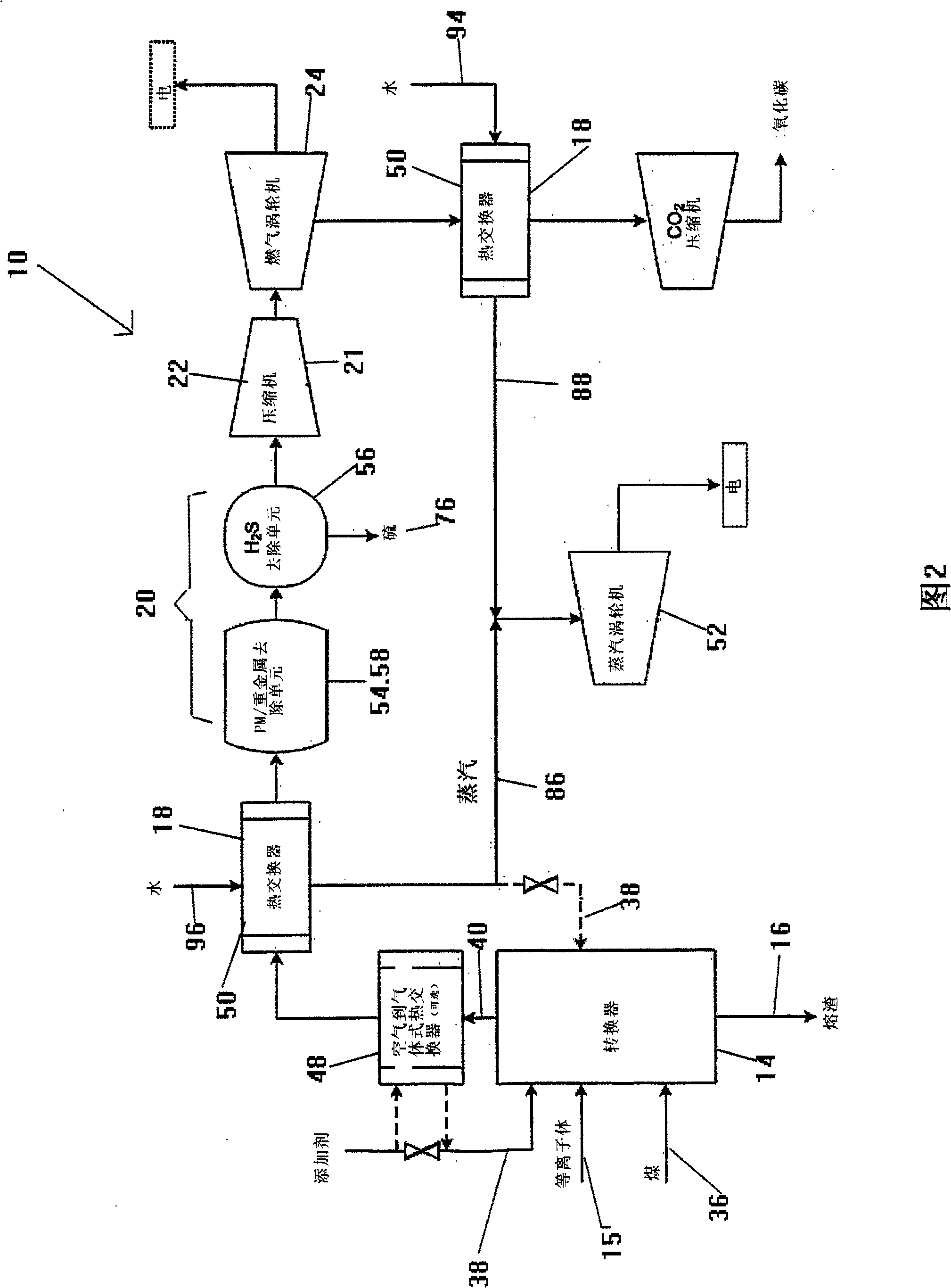

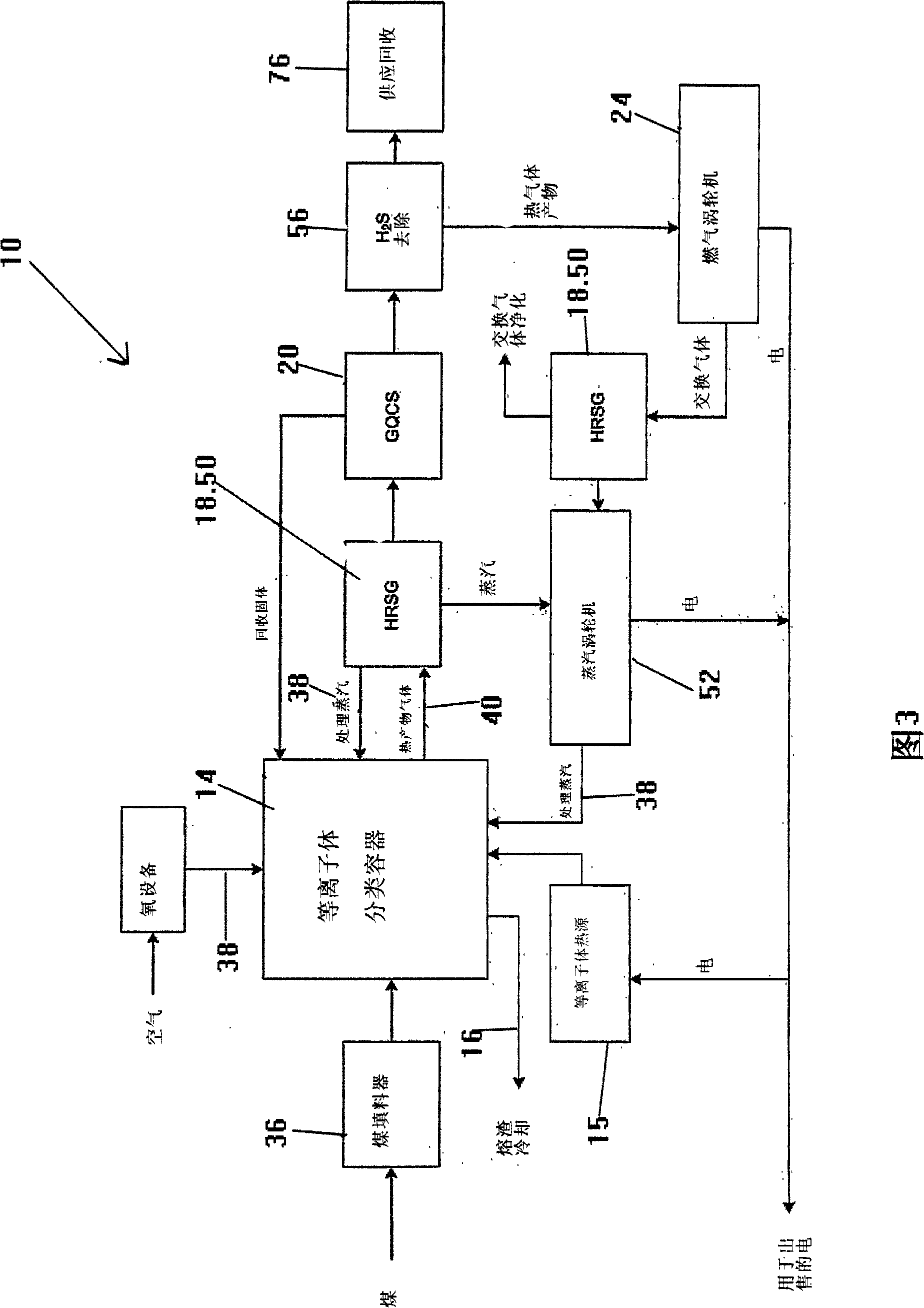

[0298] [275] Generally, the system of the present invention is used by transferring coal together with heat from a source such as a plasma heat source 15, heated air, or any other heat source that may be suitable, into the gasification reaction vessel 14, where the raw material is Apply sufficient heating to cause the gasification reaction to occur.

[0299] [276] The heating of coal results in the removal of any residual moisture and evaporation of any volatile components, thus providing a partially oxidized char product. Further heating of the partially oxidized carbon product allows the carbon to be completely converted into its gaseous component, leaving the cinder by-product, which can then be further heated and converted into slag.

[0300] [277] Additional oxygen can be injected into the gasification reaction vessel to start or accelerate the exothermic reaction that produces carbon monoxide, carbon dioxide, and carbon particles. The exothermic reaction, together with the h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com