Method for lowering molecular weight of organic substance

A technology of organic substances and low molecular weight, applied in chemical instruments and methods, inorganic chemistry, solid waste removal, etc., can solve problems such as high environmental burden, thermal damage of incinerators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

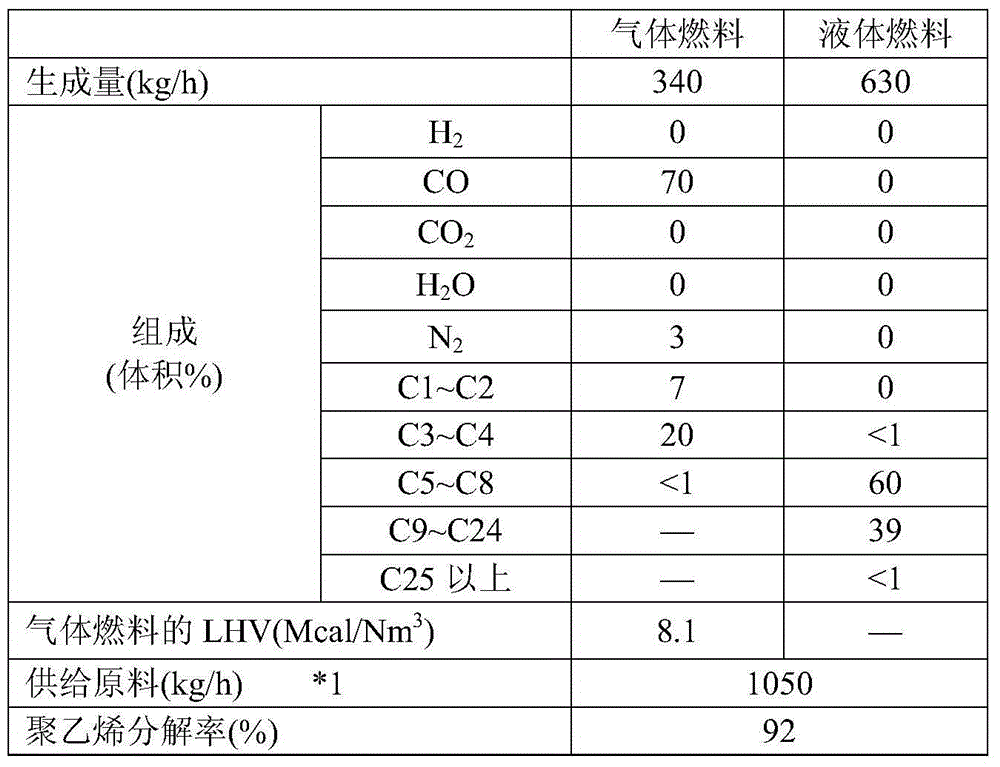

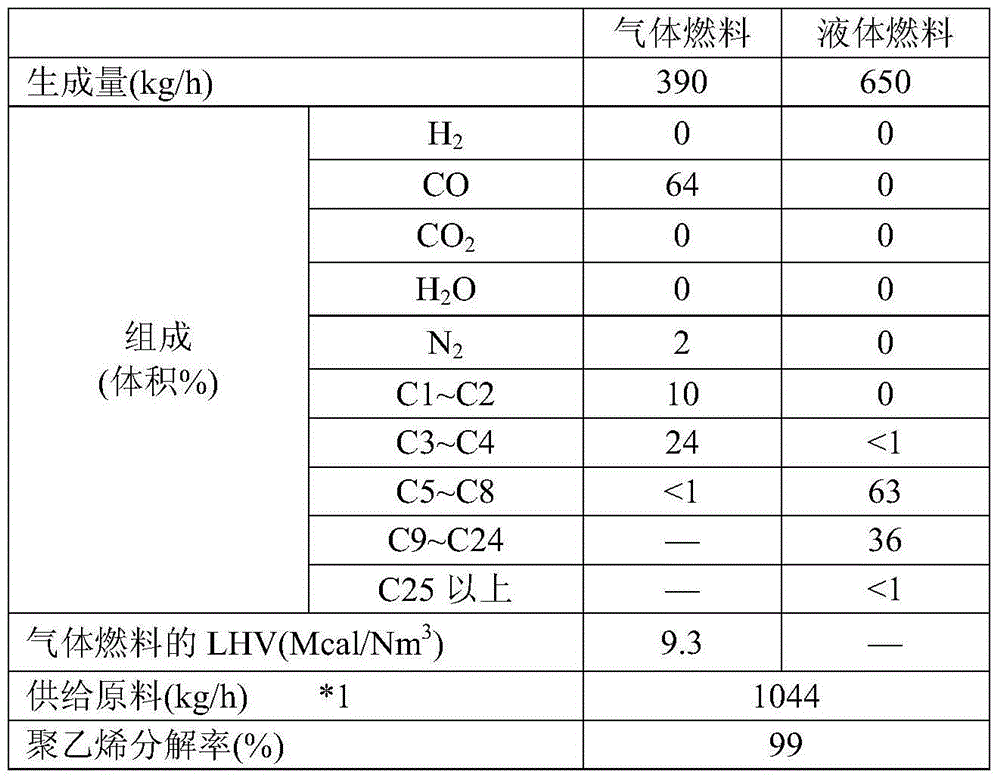

[0099] · Invention Example 1

[0100] After removing impurities such as hydrogen chloride, a branch pipe is installed on the exhaust gas (hereinafter referred to as Purified synthesis gas) generated by the Thermoselect Waste Gasification and Reforming Process (Thermoselect Waste Gasification and Reforming Process). Some hot air can be exhausted. On the downstream side of the branch pipe, a flow control valve, a steam mixer, a gas preheater, a reforming reactor (external heating type rotary furnace), and a gas cooling system for cooling the reforming reaction product gas equipped with a liquid fuel trap are arranged in sequence. device. A quantitative feeding device for waste plastics in the form of a screw feeder is arranged on the feeding side of the reforming reactor. In addition, a sampling port and a flow meter are installed on the discharge side piping of the cooled gas of the gas cooler.

[0101] The average composition of the hot gas is H 2 : 31% by volume, CO: 33% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com