A powder metallurgy process

A technology of powder metallurgy and technology, which is applied in the field of powder metallurgy forming technology, can solve problems such as difficulty in ensuring the quality of powder metallurgy products, and achieve the effect of reducing the probability of carbon deposition, improving quality, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described in further detail below in conjunction with the accompanying drawings.

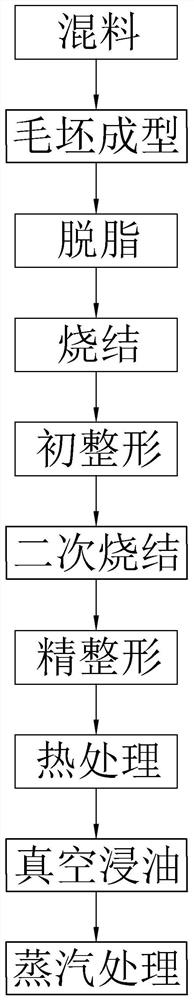

[0045] refer to figure 1 , is a kind of powder metallurgy process disclosed by the present invention, comprises the following steps:

[0046] Step 1, mixing materials, uniformly mixing metal powder and lubricant according to the proportioning ratio to form raw material powder, ready for use;

[0047] Step 2: Blank molding, put the raw material powder that has been mixed in step 1 into the powder molding machine, and the powder molding machine sends the raw material powder into the preset product mold, and presses it into the blank of the product at room temperature, and takes it out to wait use;

[0048]Step 3, degreasing, heat the blank in step 2, use natural gas or propane to heat, keep the heating temperature below 400°C, preferably keep 250-400°C, and continue the heating time until all the lubrication in the blank is guaranteed When the workpiece is d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com