Feed System

a biogenic feedstock and feed technology, applied in the field of biogenic feedstock feeding systems, can solve the problems of high process control cost, unsuitable gasifier types, and high acquisition cost of process engineering, and achieve the effect of preventing the backflow of bed material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

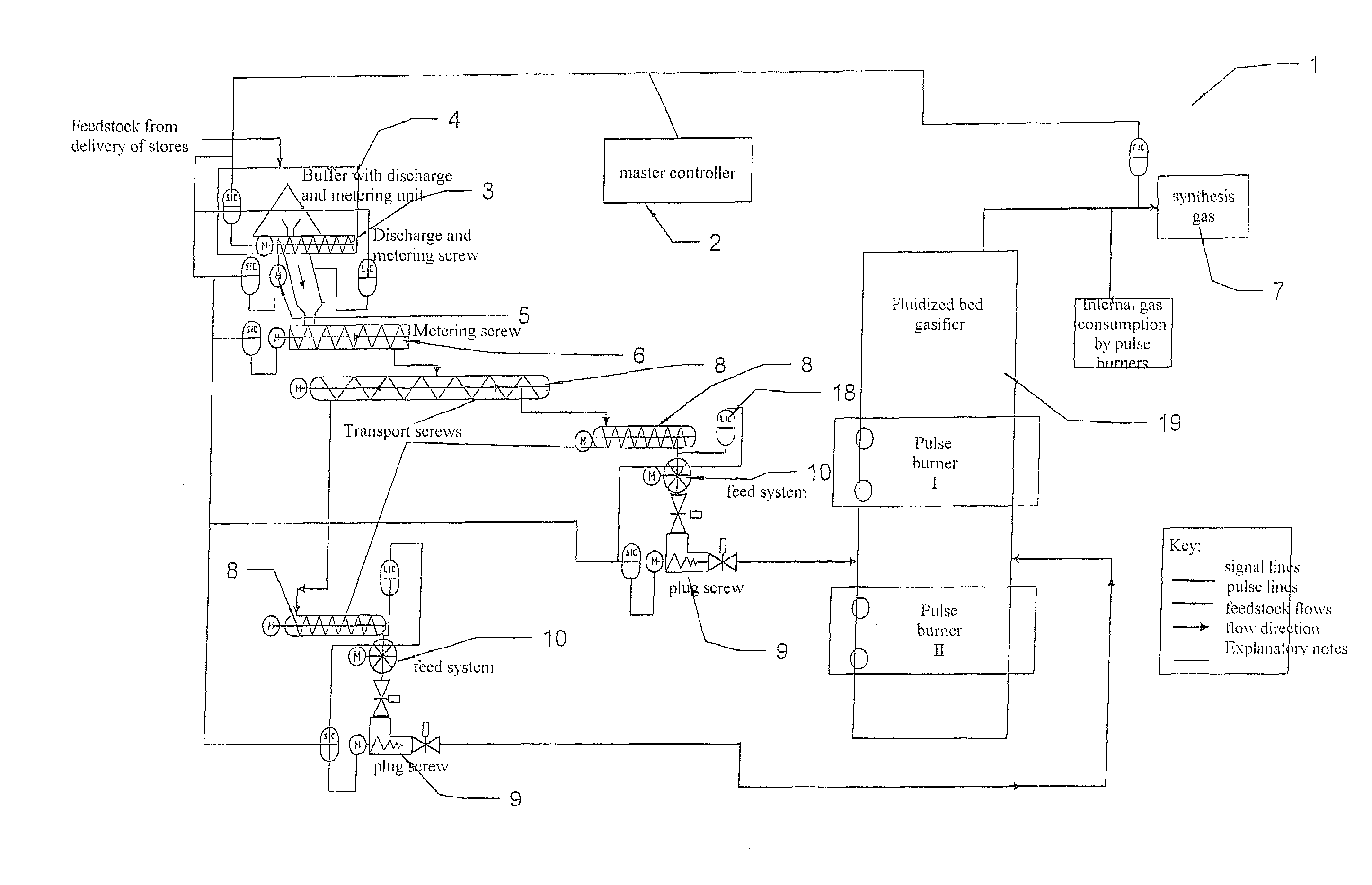

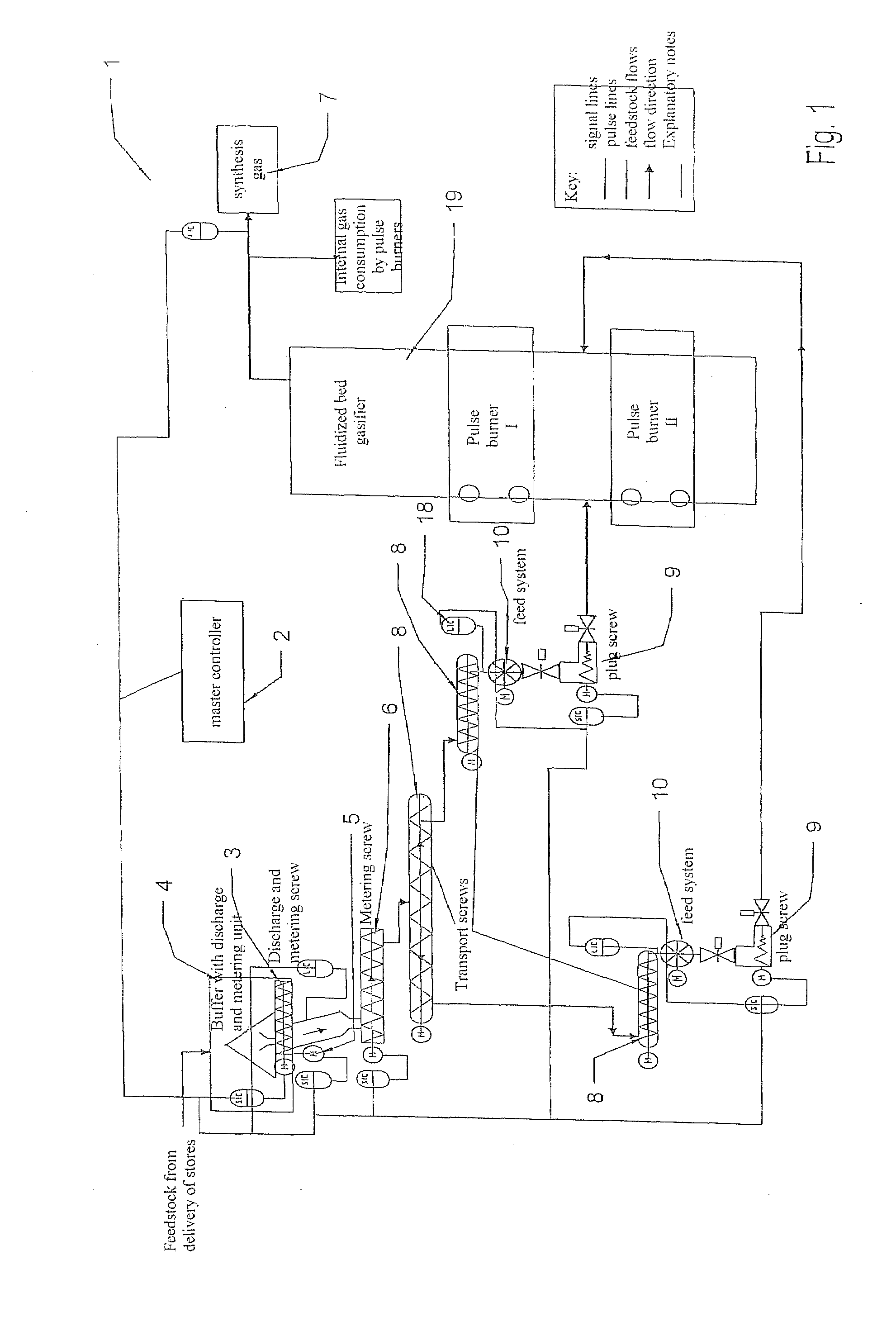

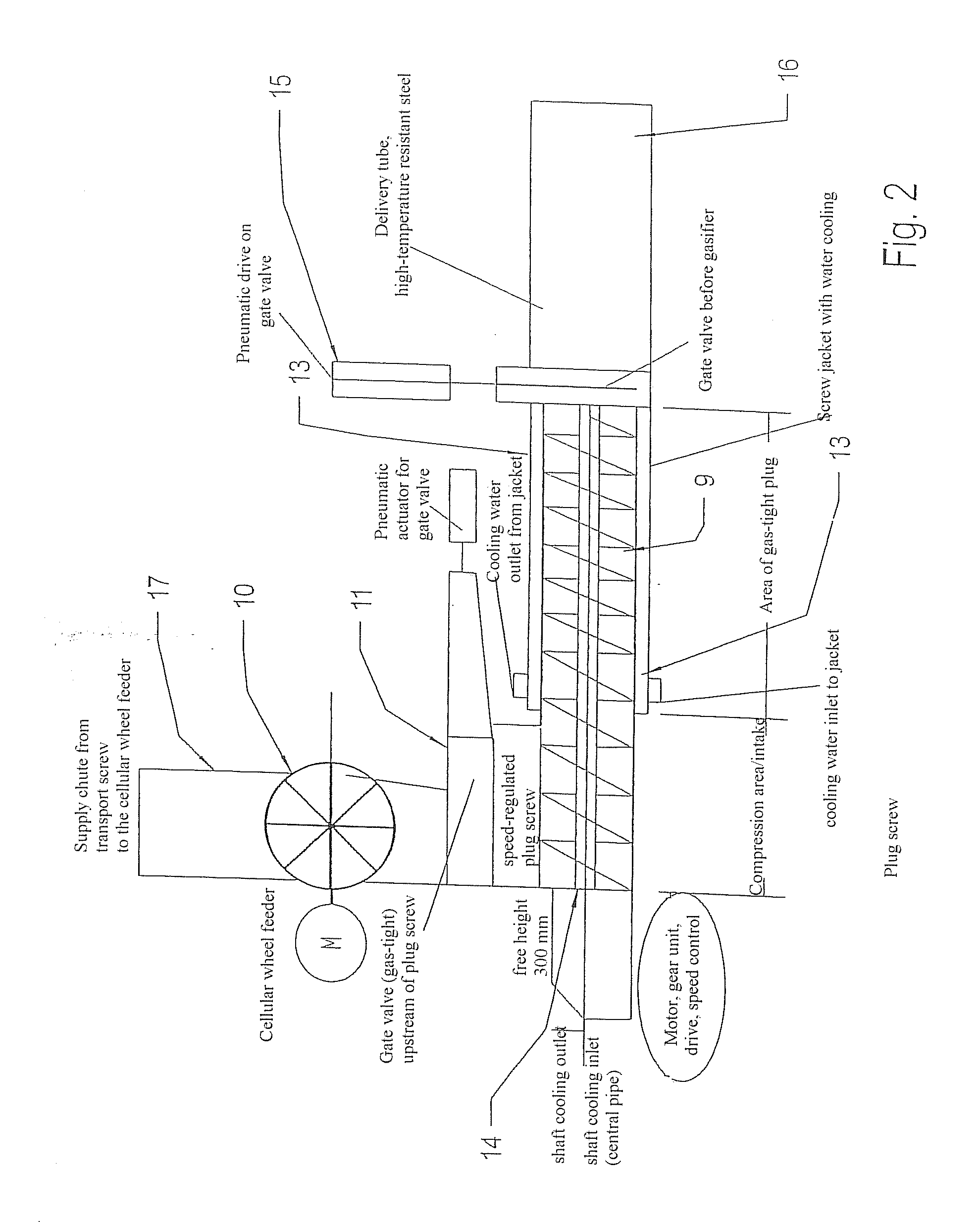

[0044]The control concept comprises the specification by the volume of synthesis gas for metering the feedstock through regulated discharge from a buffer and speed-regulated metering screws with monitoring of the fill level of the supply chutes, distribution to the feed devices and formation of the shut-off plugs in the speed-regulated feed screws, with their speed being regulated by the master controller and the fill level monitoring in the supply to the feed system. This feed system (for solids) constitutes substantial progress in fluidized bed gasification.

[0045]The discharge system 1 (FIG. 1) comprises a screw 3, the rotation speed of which is regulated by the master controller 2, and which is mounted centrally in the buffer bunker 4. The entire screw is moved over the silo base by means of a rotary drive 5, itself also speed-regulated. Speed regulation is configured such that the fill level of this screw is maintained at a constant level by the screw turning into the material h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com