Apparatus and method for coal gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

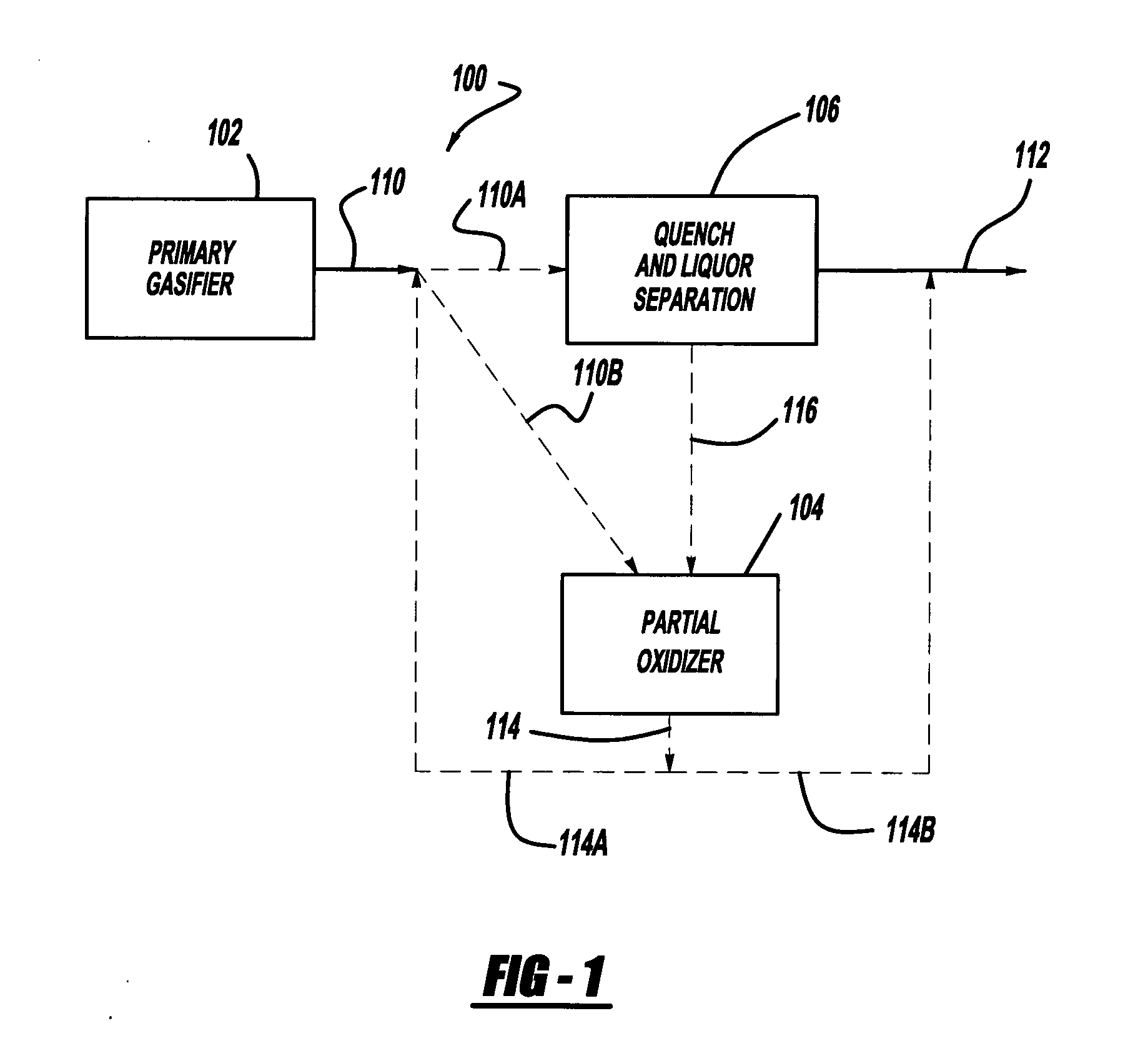

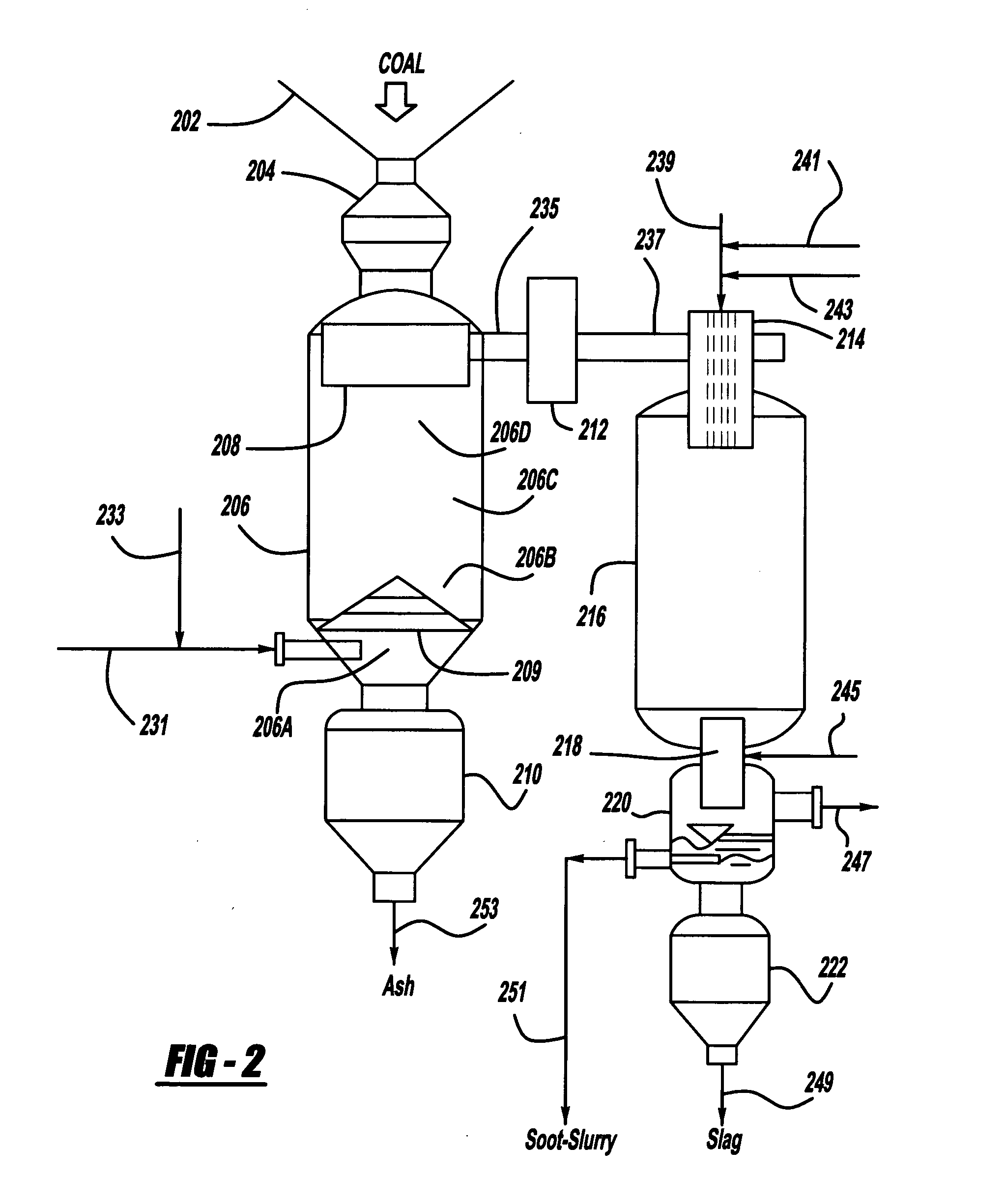

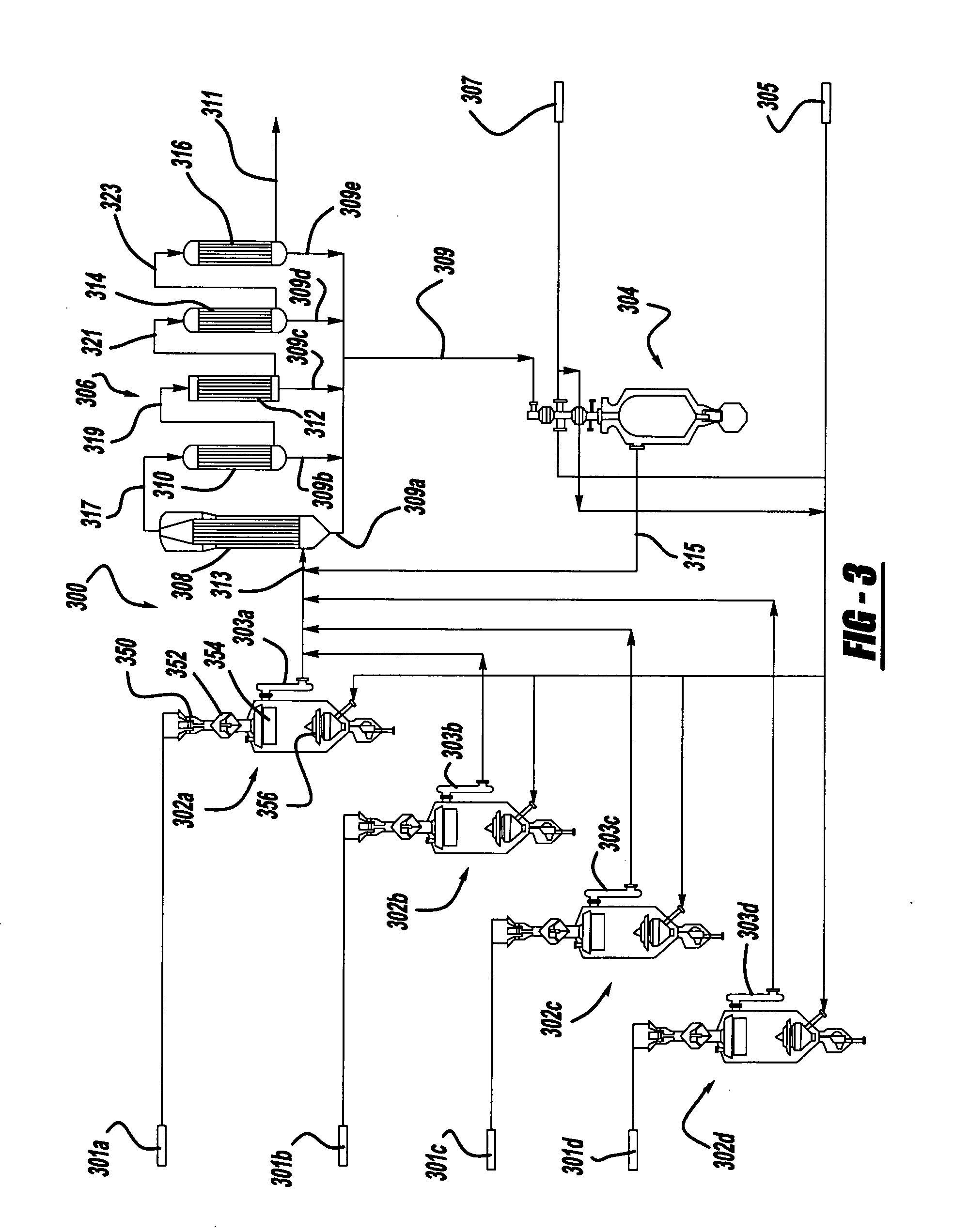

[0055] Unreactive coal (i.e., coal containing more than about 30% non-combustible contaminants) having ash content up to about 50 wt. / % is fed to a primary gasifier arranged as shown in FIGS. 2 or 3 and a primary raw gas is produced at the output of the primary gasifier having a composition by volume percent of 28.2% carbon dioxide, 0.05% hydrogen sulfide, 0.69% higher hydrocarbons, 22.66% carbon monoxide, 38.51% hydrogen, 9.5% methane and 0.39% nitrogen. Raw gas as produced above is then directed to a quenching system wherein the products of pyrolysis and other liquids are condensed out of the gas stream and passed to the input of a non-catalytic partial oxidation unit running at a reaction temperature of about 2578° F. The raw gas from the gasifier is then reformed in the partial oxidation unit, cracked and hydrolysed, and the established process in gasification reaction conditions result in the following typical gas components at the output of the partial oxidation unit expressed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com