Full-automatic leveling structure for 3D printer

A 3D printer, fully automatic technology, applied in the field of 3D printing, to achieve the effect of reducing adjustment error, improving adjustment efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

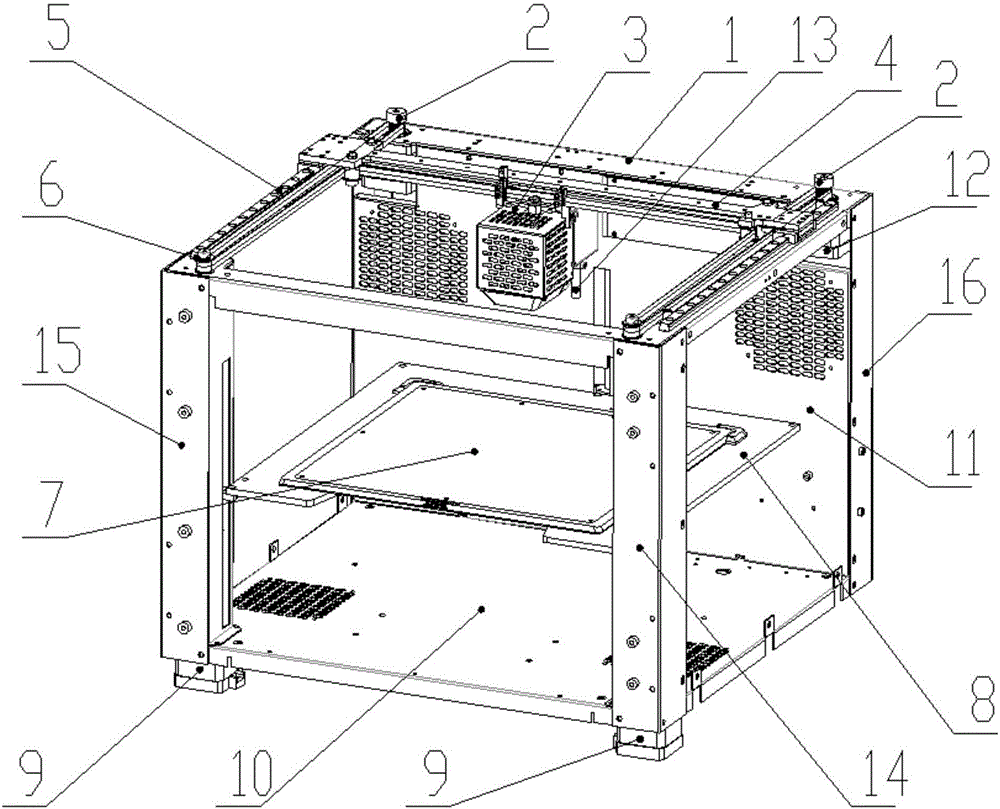

[0037] The present invention will be explained clearly and completely with reference to the accompanying drawings. Obviously, the described embodiments are only a part of the embodiments of the present invention, but do not limit the protection scope of the present invention.

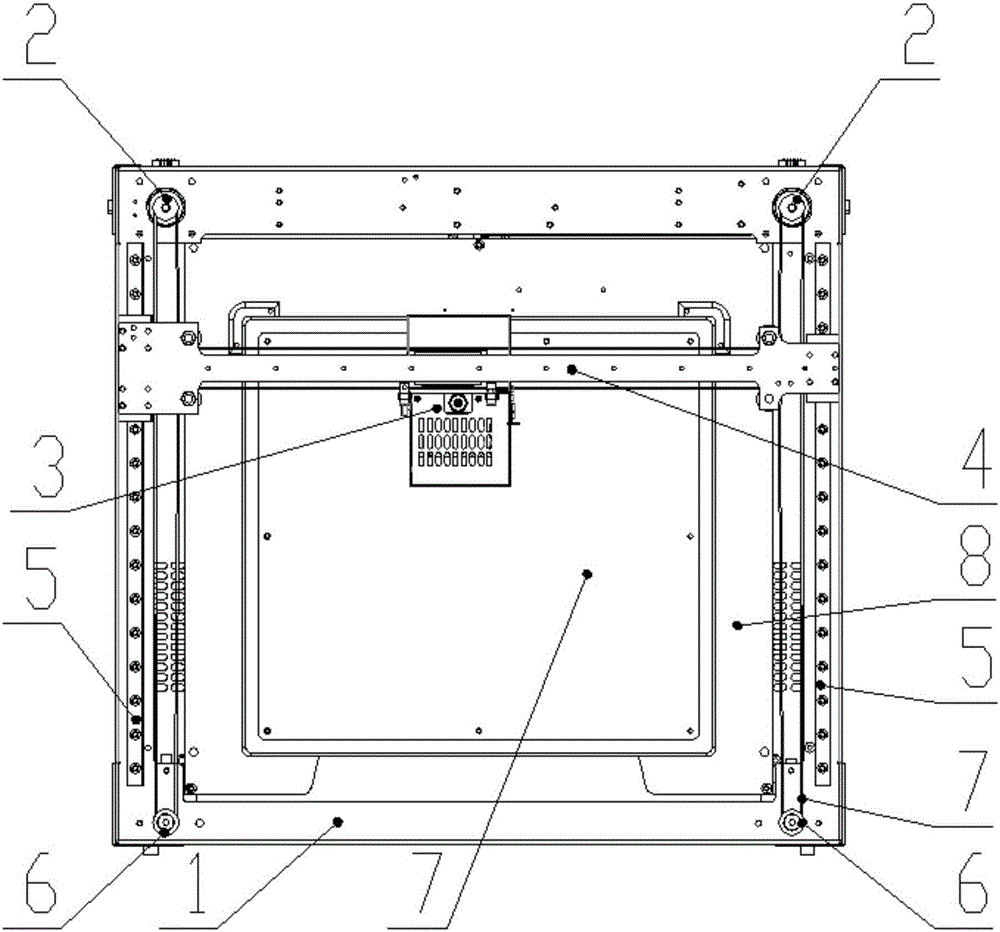

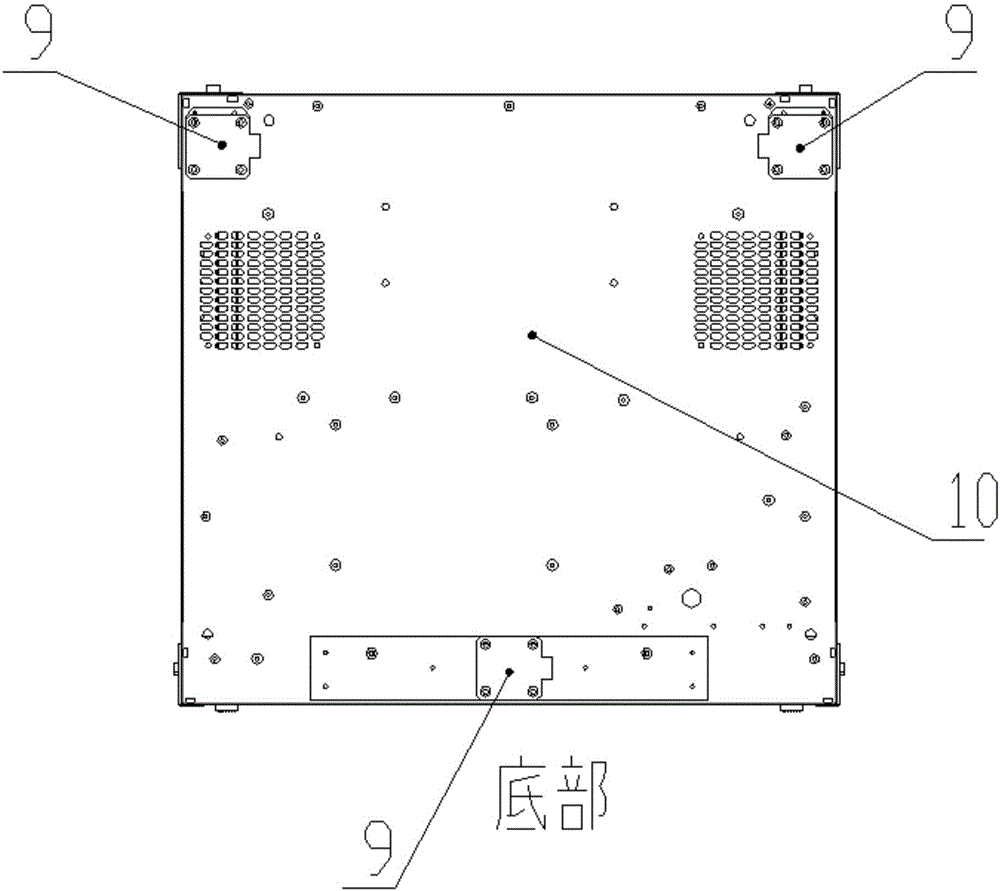

[0038] Such as figure 1 As shown, a fully automatic leveling structure for a 3D printer includes a frame, a nozzle and a hot bed plate. The frame is equipped with an XY platform, and the XY platform is equipped with an active synchronization wheel, a passive synchronization wheel, a guide rail and an X-axis fixed plate. The X-axis fixed plate is equipped with X-direction rails. The lower ends of the X-axis fixed plate are equipped with guide grooves. The guide grooves are erected on the guide rail. There is an XY stepping motor under the active synchronous wheel. The active synchronous wheel and the passive synchronous wheel are connected with The belt drives the X-axis fixed plate to move back and forth on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com