3D printer printing platform leveling method based on chasing method and hydraulic automatic leveling system

A technology of 3D printers and printing platforms, which is applied in the direction of fluid pressure actuators, mechanical equipment, servo motors, etc. It can solve the problems of affecting printing accuracy, printing head wire plugging, and insufficient bonding force, so as to improve adjustment efficiency and ensure adjustment Accuracy and reduction of printing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

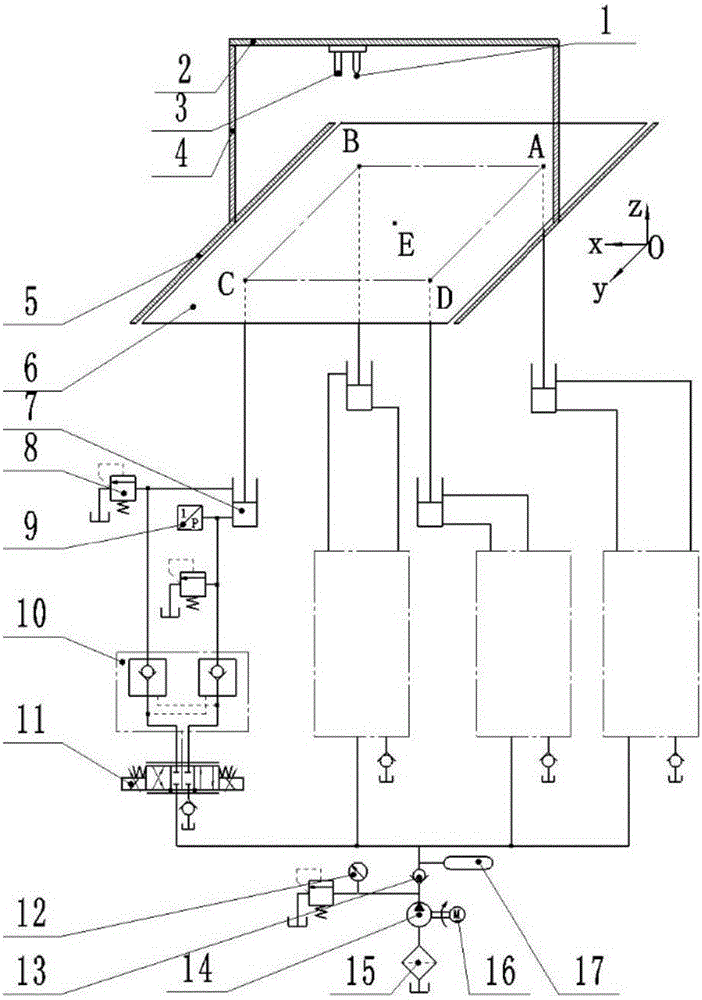

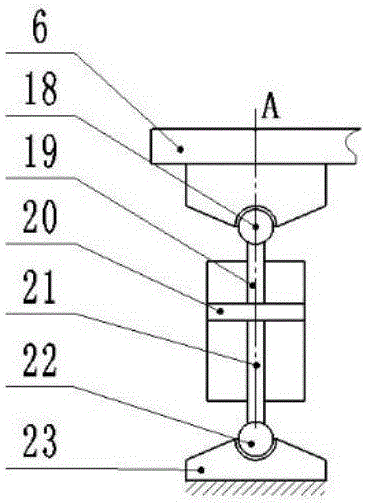

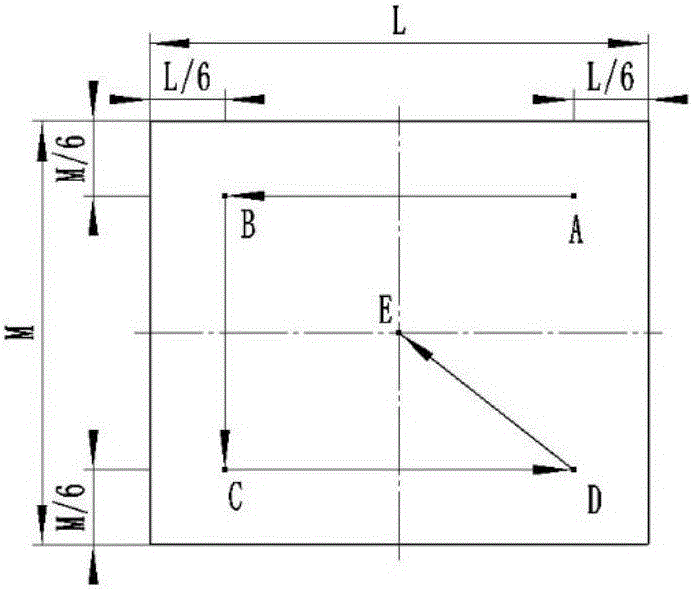

[0020] The mechanical structure part and hydraulic leveling circuit of the 3D printer such as figure 1 As shown, the mechanical structure part includes the printing platform (6), the printing head (1), the X-guiding guide (2), the Y-guiding guide (5) and the Z-guiding guide (4), and the X-guiding guide (2) and the printing platform (6) are parallel, the X-guiding rail (2) is perpendicular to the Y-guiding rail (5), the Z-guiding rail (4) is perpendicular to the Y-guiding rail (5), and the Y-guiding rail (5) is set on the printing platform (6) On both sides, the X guide rail (2), the Y guide rail (5) and the Z guide rail (4) are the three-way adjustment structure of the print head (1), and the print head (1) and distance measuring sensor (3) are all set on On the X guide rail (2), the parallel installation of the print head (1) and the distance measuring sensor (3); ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com