Light-dimmer driving circuit

A dimming drive and circuit technology, applied in the field of dimming, can solve the problems of limited dimming range of pure analog circuits, reduce power factor value, destroy sine wave waveform, etc., achieve flicker-free dimming and constant current output, and ensure safety and stability, and improve the effect of constant current accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

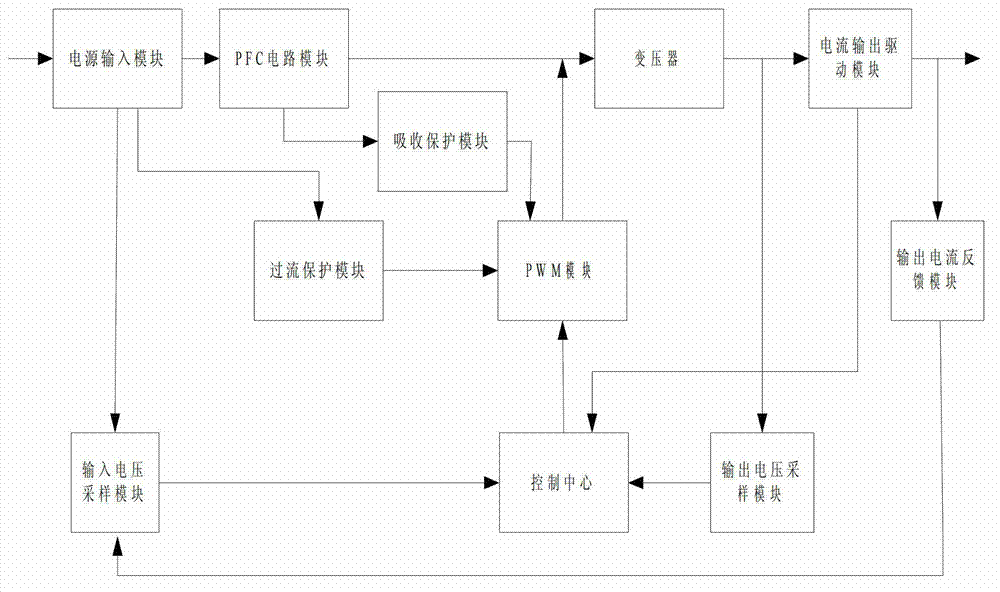

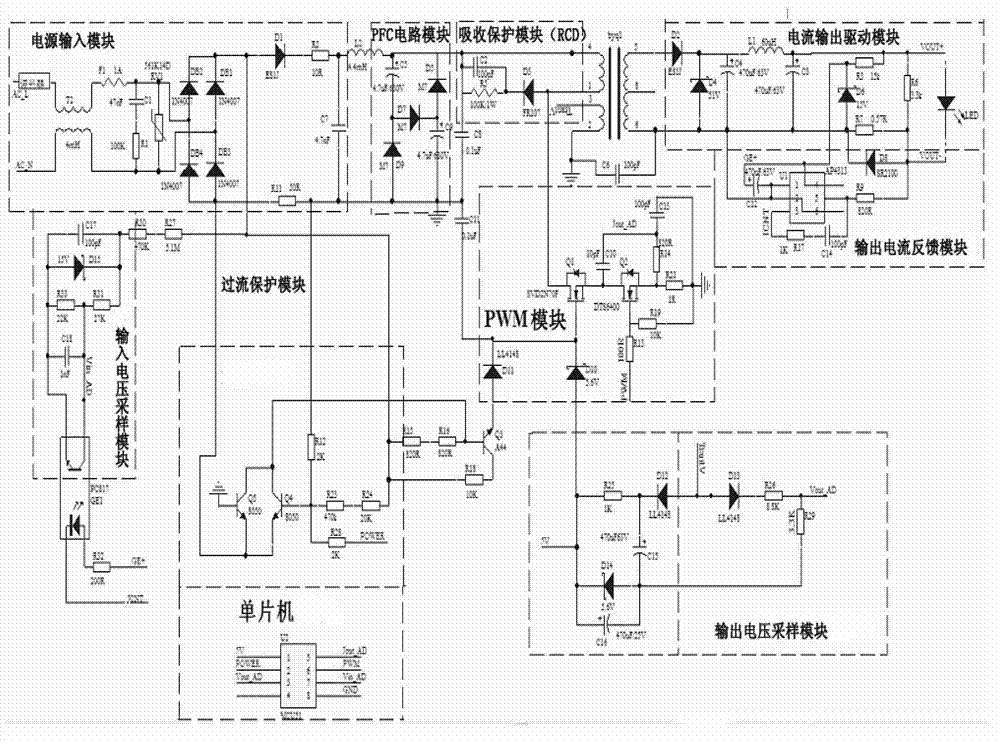

[0031] like figure 1 As shown, a dimming drive circuit includes a power input module mainly used to rectify and filter an input voltage signal, a PFC circuit module used to adjust the power factor of the dimming drive circuit, and used to protect the switch tube in the PWM module. The absorption protection module is used for the transformer to step down the voltage signal, the current output drive module that drives the current output according to the transformed voltage signal, and the PWM module that controls the output power of the current output drive module according to the control signal of the control center. The PWM module outputs a PWM signal, controls the overcurrent protection module of the PWM module to turn on or off through the input current of the power input module, and feeds the output current back to the output current feedback module of the input voltage sampling module to sample the input voltage signal, and then The input voltage sampling signal is input t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com