Large-relative-aperture high-precision refraction-reflection star sensor optical system

A star sensor and relative aperture technology, applied in the field of optical systems, can solve the problems of slow image refresh rate, long integration time, low incident light energy, etc. Effect of Entrance Pupil Diameter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

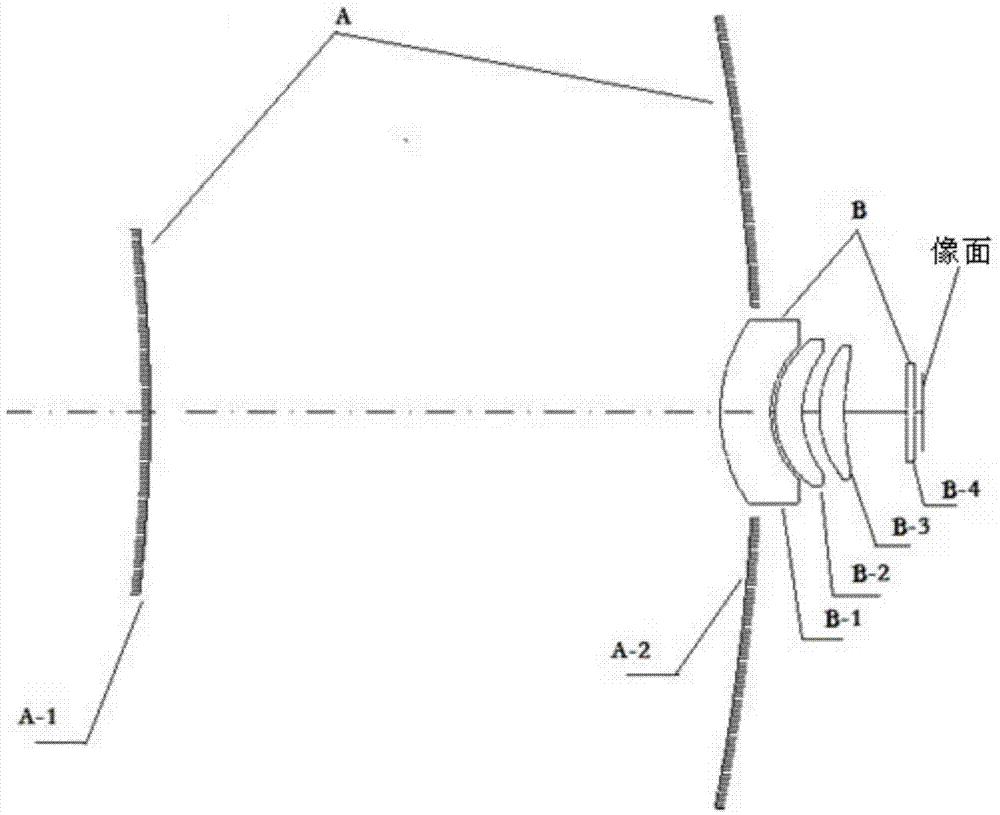

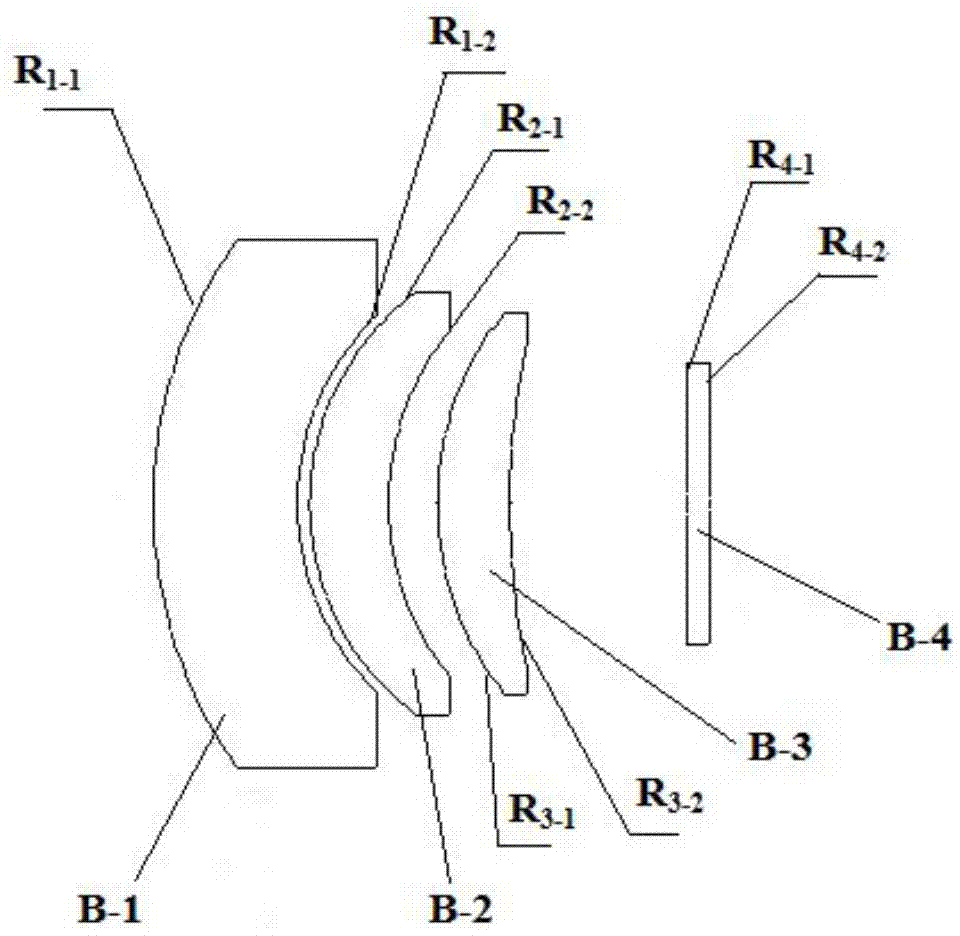

[0037] like figure 1 As shown, the front mirror group A with positive refractive power and the rear mirror group B with positive refractive power are respectively set according to the order of light incidence, and the front mirror group A is composed of secondary reflector A-1 and primary reflector A-2 composition, focal length f A '=247.63mm; the rear mirror group B is composed of a first convex-concave lens B-1, a second convex-concave lens B-2, a third convex-concave lens B-3 and parallel plate glass B-4, and the first convex-concave lens B-1, the second convex-concave lens B-2 and the third convex-concave lens B-3 are all spherical lenses with focal length f B '=141.811 mm.

[0038] The air gap between the front mirror group A and the rear mirror group B is 68.034mm.

[0039]The air separation between the secondary mirror A-1 and the primary mirror A-2 is 72 mm.

[0040] The air gap between the first lenticular lens B-1 and the second lenticular lens B-2 was 0.5 mm.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com