Sorting height adjustable vibration disk

A vibrating plate, adjustable technology, applied in the direction of sorting, etc., can solve the problems of not being able to screen multiple products of different specifications at the same time, not having grooves for multiple materials, not suitable for mass production, etc., to save adjustment time and ensure vertical , the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

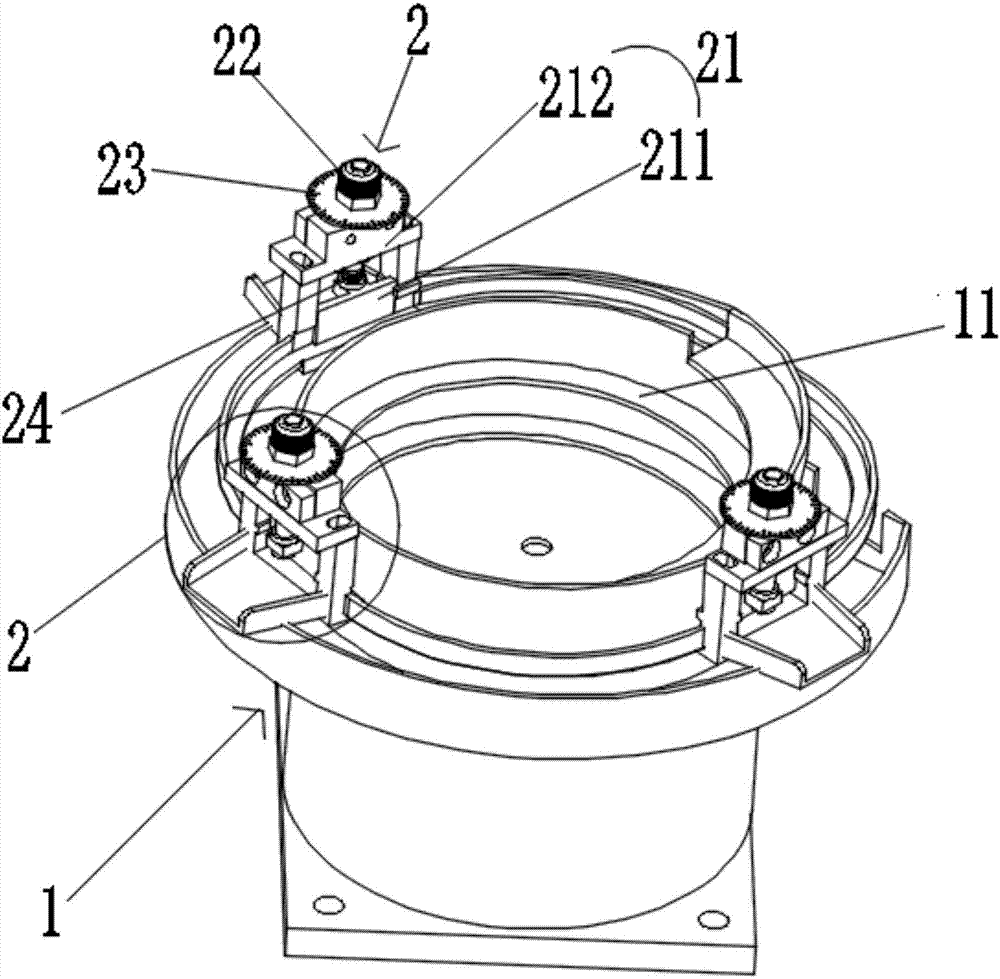

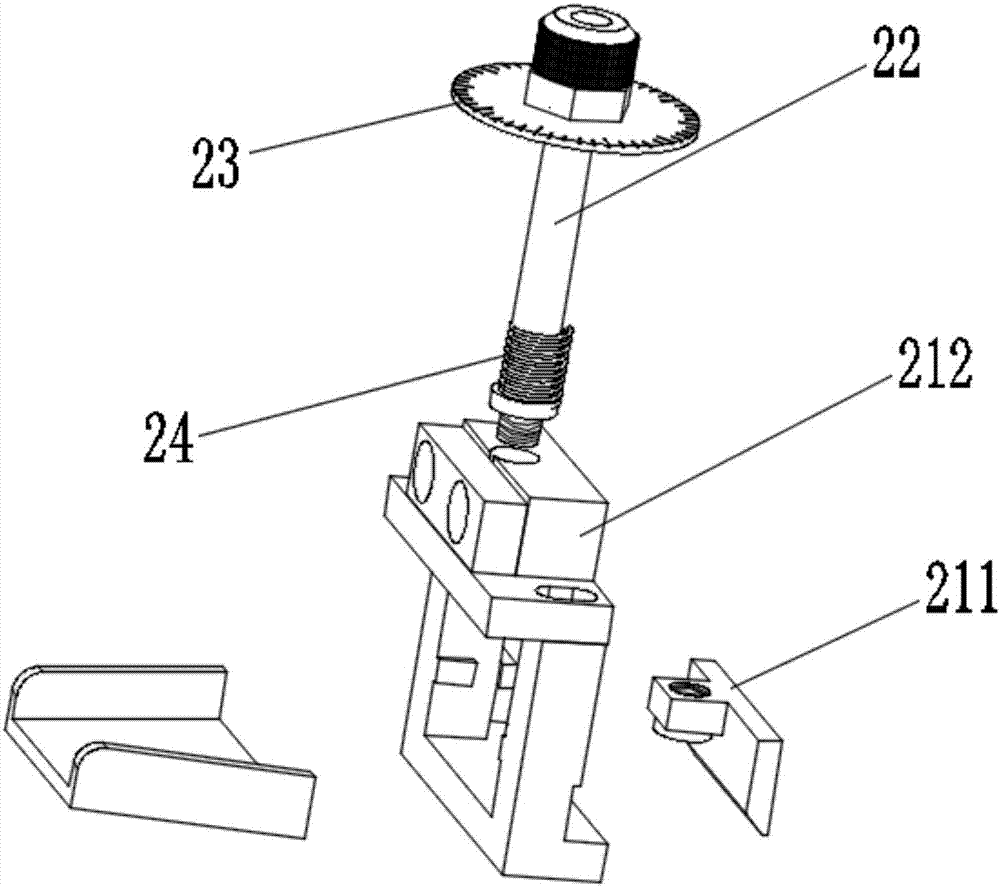

[0020] see Figure 1 to Figure 2 , the present invention provides a sorting height-adjustable vibration plate, including a vibration plate body 1 and at least one sorting unit 2; the vibration plate body 1 includes a spiral material distribution track 11; the sorting unit 2 is arranged on the spiral sorting The outer ring of the material track 11, the sorting unit 2 includes a gate 21, an adjustment screw 22 and a dial 23; the gate 21 includes a gate body 211 and a gate frame 212; the gate 21 frame is arranged on the outer circle of the spiral material distribution track 11; the gate The body 211 is set in the gate frame 212 and forms a sorting port with the spiral material distribution track 11; the gate frame 212 and the gate body 211 are both provided with internal threads that match the adjusting screw 22; the lower end of the adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com