Manufacturing method for shock absorber aluminum barrel

A manufacturing method and shock absorber technology, applied in manufacturing tools, casting molding equipment, casting molds, etc., can solve the problems of poor compactness of parts, high defect rate, limited service life of parts, etc., to improve quality and accuracy, reduce Production cost, effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

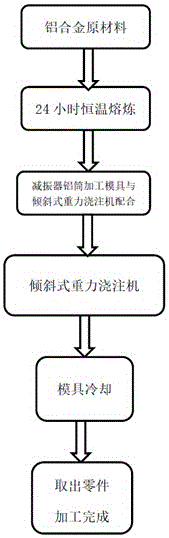

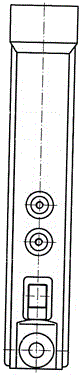

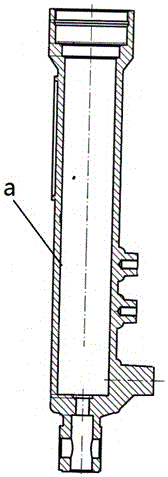

[0020] Such as figure 1 As shown, a manufacturing method of the shock absorber aluminum cylinder solves the technical problems of poor compactness of parts formed by traditional die-casting, which leads to easy deformation during use and high defect rate during production. Including: (1) The step of putting aluminum alloy raw materials into a 24-hour constant temperature melting furnace; through this step, it can ensure that the melting state of the raw materials is in a constant state, and the temperature difference is kept at a constant level, which is conducive to the subsequent production of more precise parts . (2) The step of matching the processing mold of the aluminum cylinder of the shock absorber with the inclined gravity pouring machine; assembling the processing mold of the triple plate parts with the inclined gravity pouring machine, and the casting parts can be made due to the inclined type during use. The process runs more smoothly, the formed parts have a high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com