Mask and manufacturing method thereof

A manufacturing method and mask technology, applied in semiconductor/solid-state device manufacturing, ion implantation plating, coating, etc., can solve the problems affecting the deposition quality of organic light-emitting layers, and the quality and accuracy of metal masks cannot be well satisfied Requirements, issues affecting product quality, etc., to achieve the effect of improving restrictions, increasing robustness, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In view of the aforementioned technical problems, the present invention proposes a mask, which mainly includes:

[0055] a substrate having a first surface and a second surface opposite to each other, the substrate has a plurality of openings penetrating through the substrate, and the material of the substrate is a material capable of performing a semiconductor etching process;

[0056] A mask pattern layer located on the first surface, the material of the mask pattern layer is a material capable of performing a semiconductor etching process;

[0057] The mask pattern layer has a pattern area and a shielding area, each of the pattern areas has at least one through hole, and the opening exposes the pattern area, and each of the openings is opposite to one of the pattern areas and exposes For all through holes in the pattern area, the shielding area is located outside the pattern area and opposite to the substrate.

[0058] The mask plate of the present invention is made...

Embodiment 2

[0084] The present invention also provides a method for manufacturing a mask, such as Figure 7 As shown, it mainly includes the following steps:

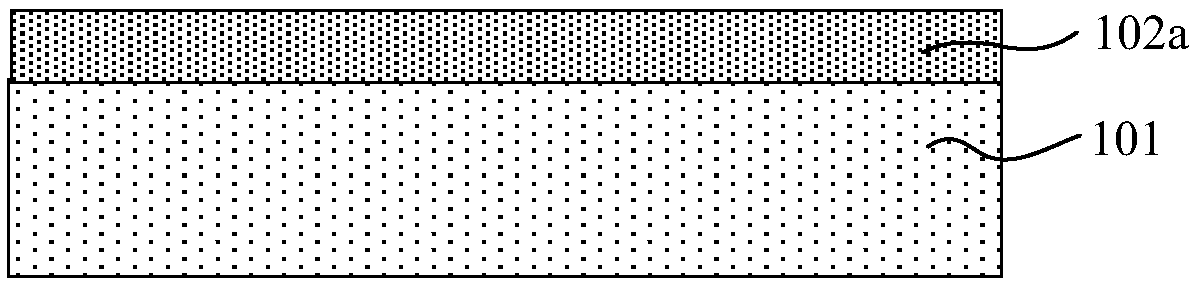

[0085] Step S1, providing a substrate having a first surface and a second surface opposite to each other, and a mask layer is formed on the first surface of the substrate;

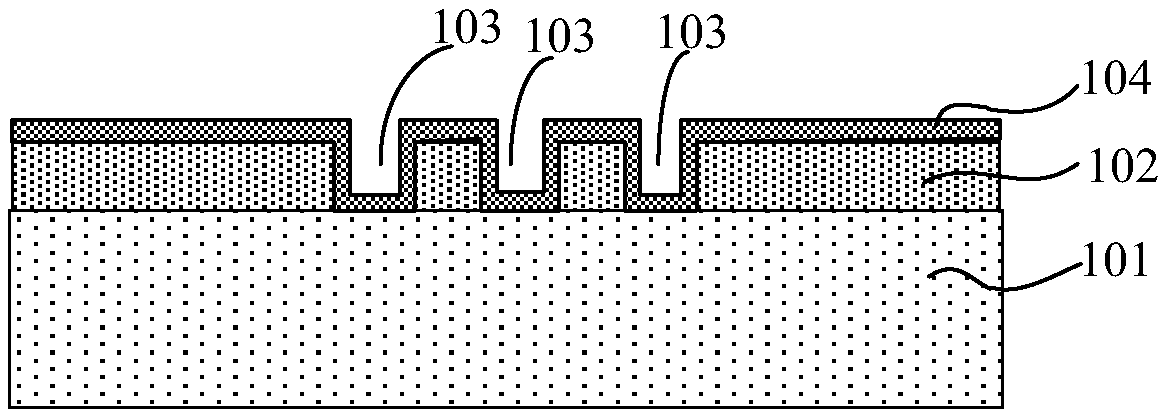

[0086] Step S2: Etch the mask layer using a semiconductor etching process according to a predetermined pattern to form a mask pattern layer, the mask pattern layer has a pattern area and a shielding area, each of the pattern areas has at least one pass a hole, the shielding area is located outside the graphic area;

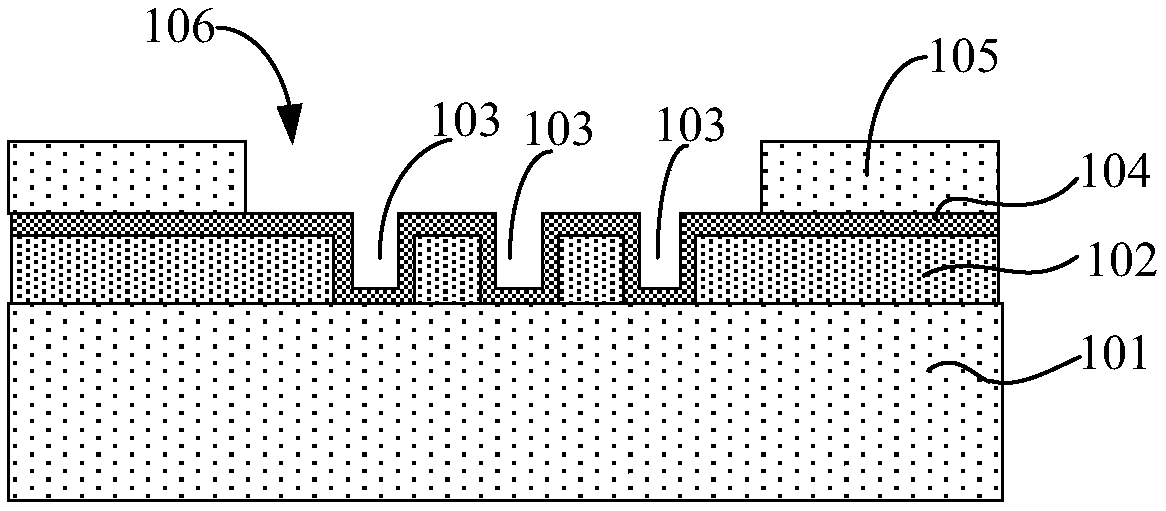

[0087] Step S3 , etching the substrate from the second surface by using a semiconductor etching process to form a plurality of openings penetrating through the substrate, wherein the openings expose the pattern area.

[0088] Below, refer to Figure 1A to Figure 1J The manufacturing method of the mask plate of the present invention is described i...

Embodiment 3

[0138] It is worth mentioning that, in order to obtain the mask in the first embodiment, the order of the method steps in the embodiment can also be changed to prepare and obtain the corresponding mask, for example, in order to obtain image 3 mask structure in , the following steps can also be performed:

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com