Die locking mechanism and method for two-plate injection molding machine to bear spiral pairs to synchronously follow movable template

A technology of moving platen and injection molding machine, which is applied in the field of clamping mechanism of two-platen injection molding machine bearing screw pair synchronously following the moving platen, which can solve the problems of high equipment manufacturing cost, troublesome mold adjustment, difficult equipment maintenance, etc., and achieve manufacturing cost And the effect of low maintenance cost, shortened production cycle, and shortened mold clamping stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

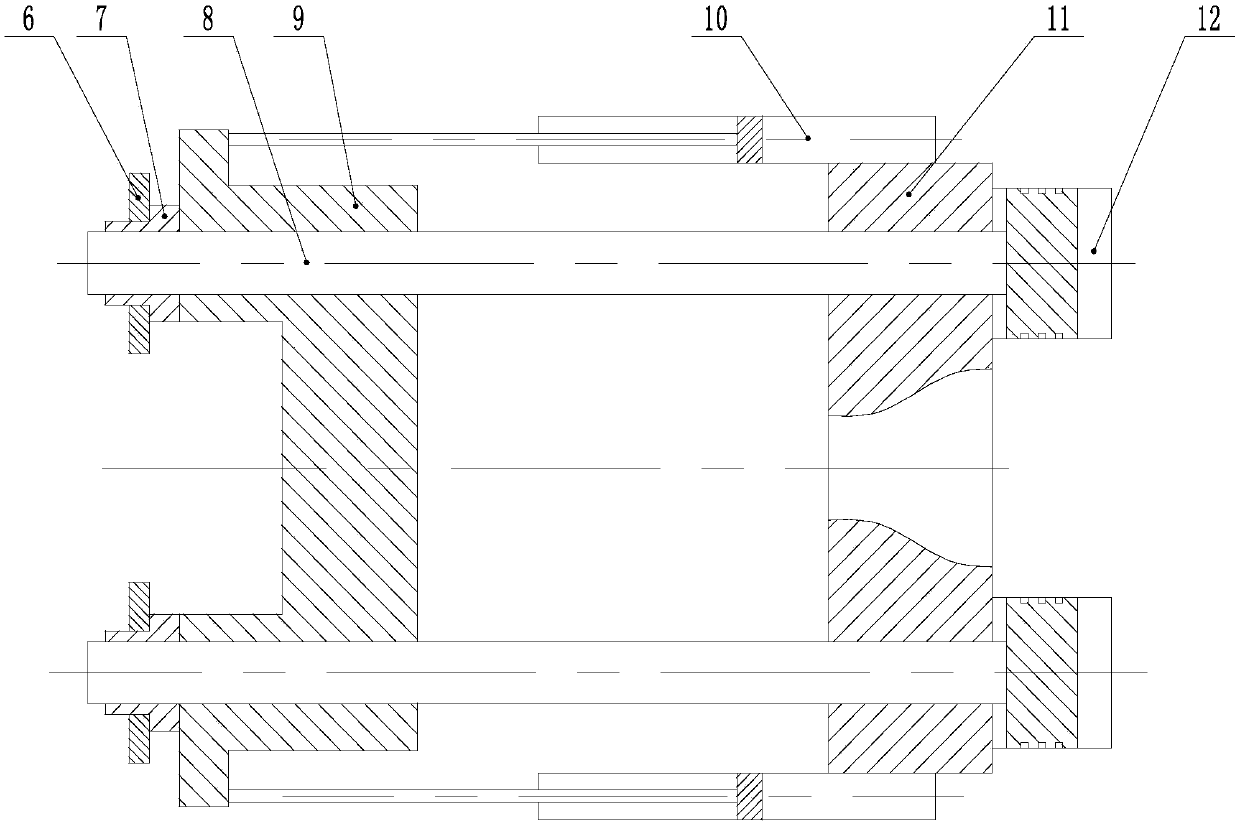

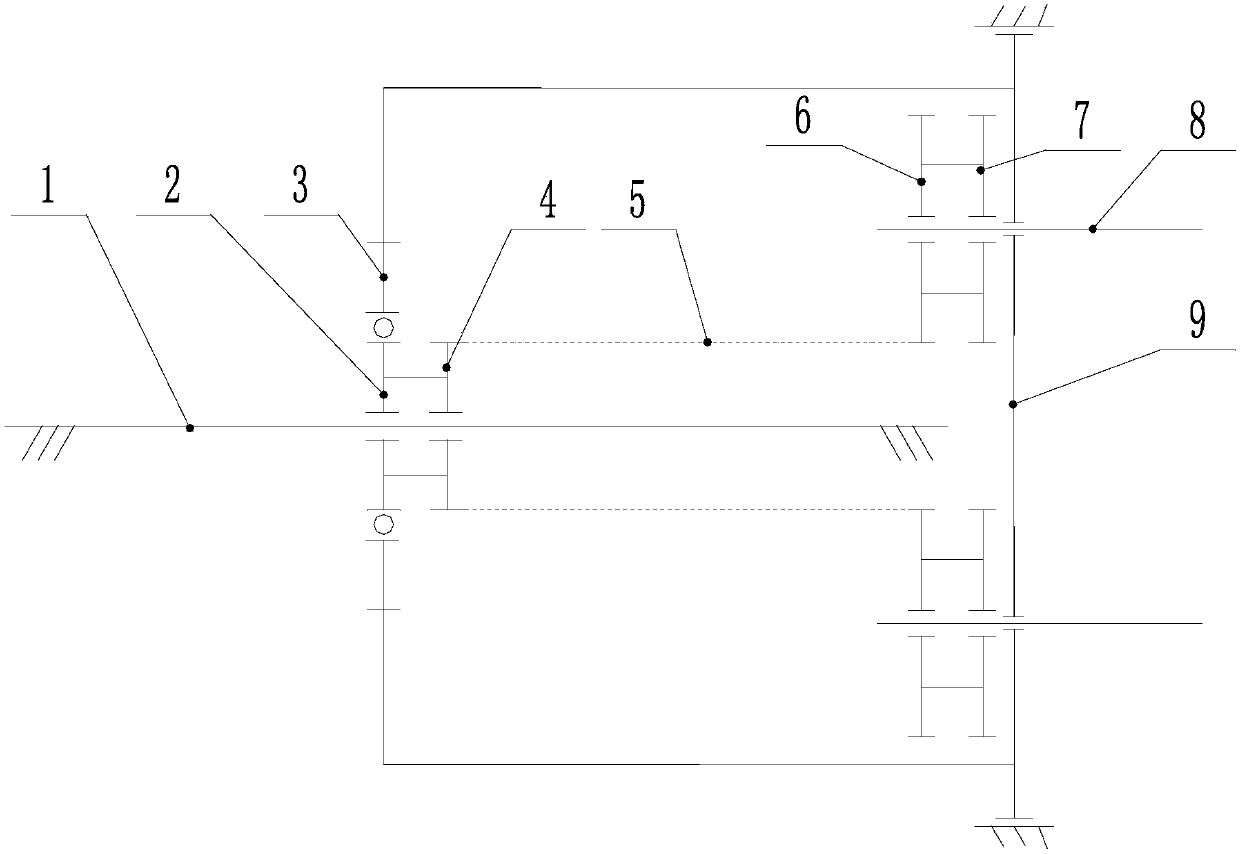

[0031] In this embodiment, a clamping mechanism for a two-platen injection molding machine that carries a screw pair and follows a moving template synchronously, such as figure 1 As shown, it includes a matched movable template 9 and a fixed template 11. The movable template and the fixed template are connected by four pull rods 8. On each pull rod, an end that is positioned outside the movable template is provided with a clamping nut 7. One end is provided with clamping oil cylinder 12, and clamping oil cylinder is installed on the outside of fixed formwork, and pull rod and clamping bearing nut form the first rolling screw pair; figure 2 As shown, a support seat 3 is provided on the outside of the movable formwork, and a second scroll screw pair is provided on the support seat. The second scroll screw pair includes a screw 1 and a screw nut 2. The screw and the pull rod are arranged in parallel and fixed on the frame. , the screw nut is arranged on the screw rod, and the ou...

Embodiment 2

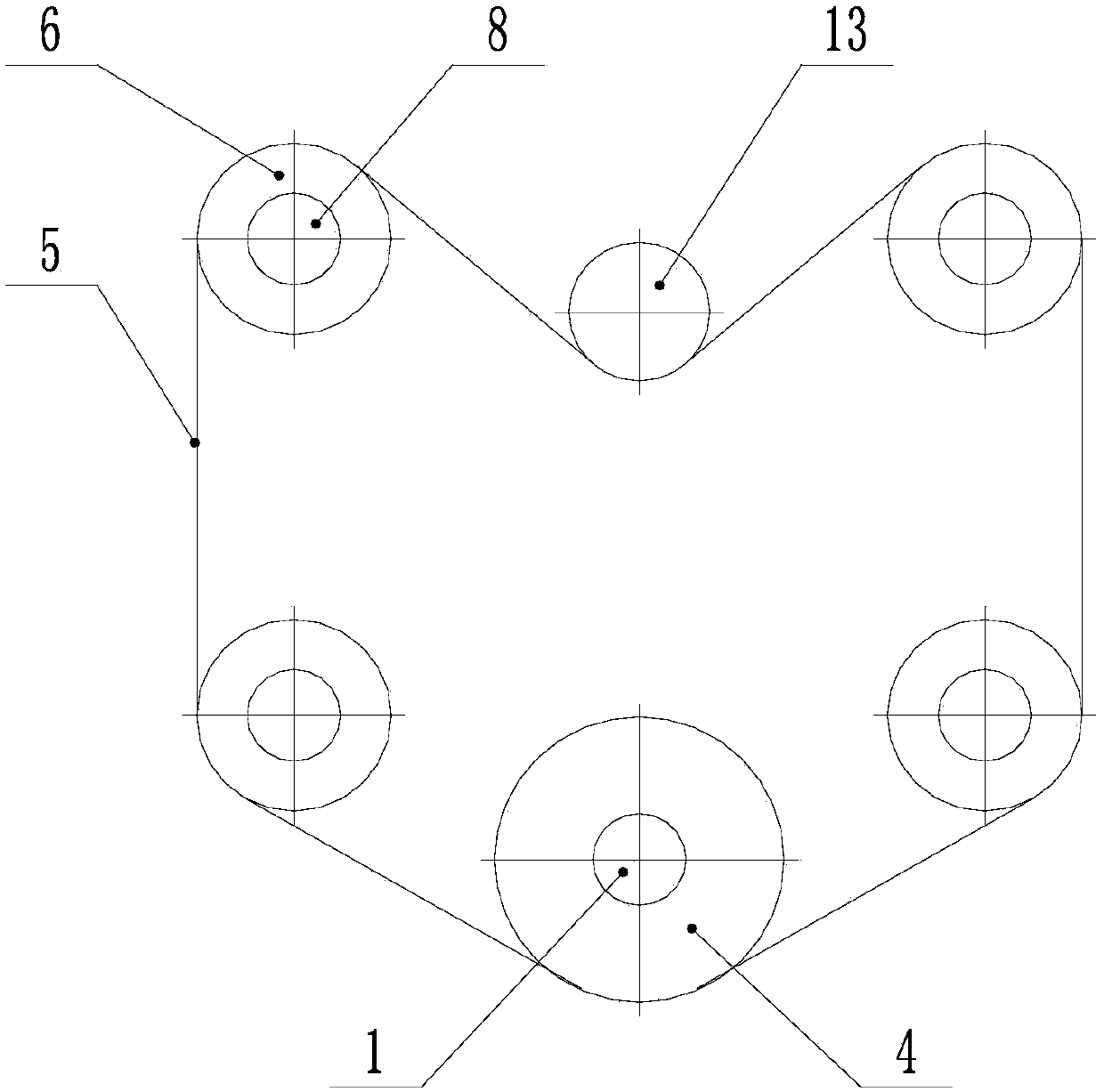

[0039] This implementation is a clamping mechanism for a two-platen injection molding machine that carries a screw pair and follows the moving template synchronously. Compared with Example 1, the difference lies in: Figure 4 As shown, there are four tie rods, and each tie rod is connected with the same clamping oil cylinder, and the clamping oil cylinder is embedded in the fixed template in a circular structure. In this structural form, the fixed platen and the movable platen are in a circular shape, a plurality of tie rods are distributed along the circumferential direction of the top platen, and the clamping cylinder is in the shape of a ring and embedded in the fixed platen. When the tonnage of the injection molding machine is large, Adopting this structural form can significantly increase the area of the mold clamping cylinder, thereby providing a large mold clamping force at a lower system pressure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com