Core material of dot matrix laminboard and manufacturing method of core material by using extruding and interlocking

A manufacturing method and sandwich panel technology, applied in the direction of chemical instruments and methods, lamination, lamination devices, etc., can solve the problems of high cost, complicated preparation process, difficult mass production, etc., and achieve low cost, simple process, strong The effect of explosion protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

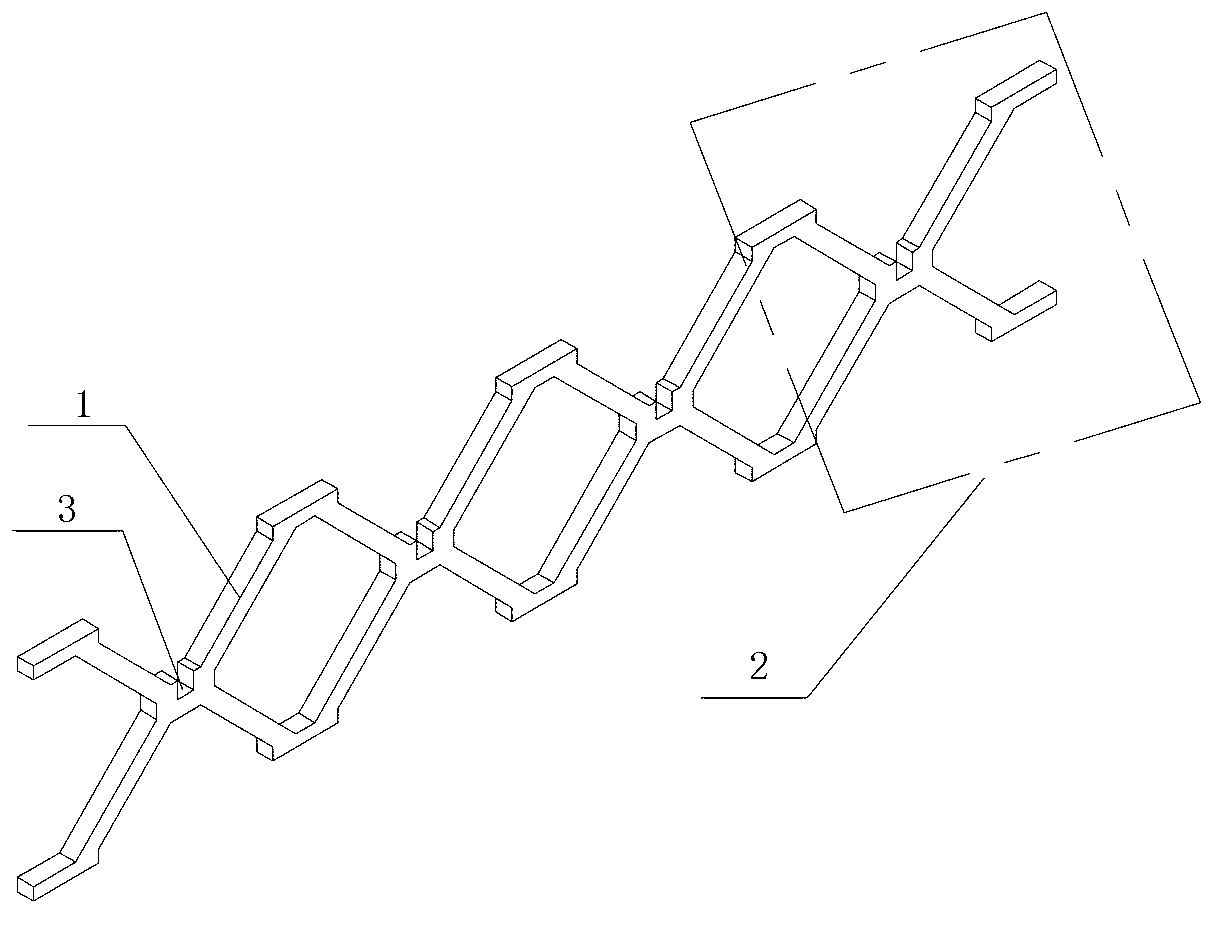

[0018] Specific implementation mode one: combine Figure 1-Figure 4 Explain that the core material of this embodiment includes a plurality of connecting strips 1, the thickness of which is equal to that of the plurality of connecting strips 1, and each connecting strip 1 is formed by connecting a plurality of 'X'-shaped units 2 sequentially along the transverse top end, and 'X' There is a notch 3 above the intersection of the 'shaped unit 2, and the width of the notch 3 is equal to the thickness of the connecting strip 1. A plurality of connecting strips 1 are divided into two groups and are respectively defined as a horizontal group and a vertical group. The horizontal group and the The number of connecting bars in the longitudinal group is equal, the connecting bars 1 in the horizontal group are arranged in parallel at equal intervals in turn, and the connecting bars 1 in the longitudinal group are vertically arranged with the connecting bars 1 in the corresponding horizontal...

specific Embodiment approach 2

[0019] Embodiment 2: The thickness of each connecting bar 1 in this embodiment is 0.1-10mm, and other method steps are the same as Embodiment 1.

specific Embodiment approach 3

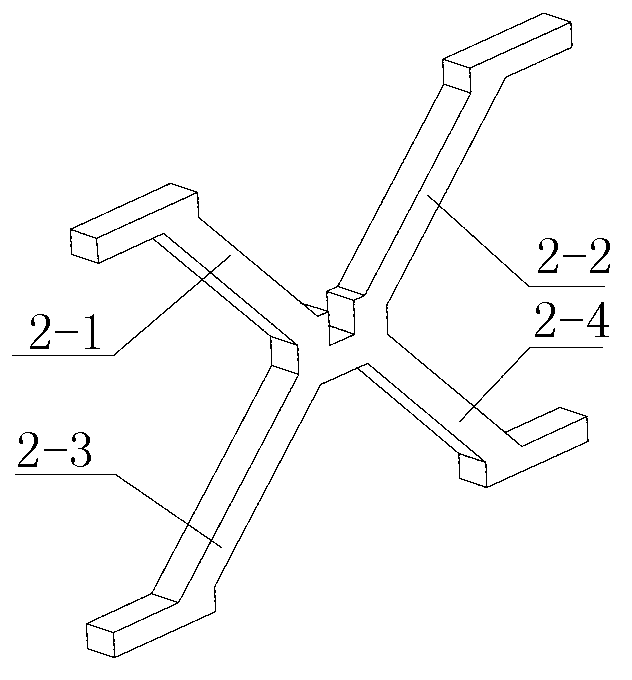

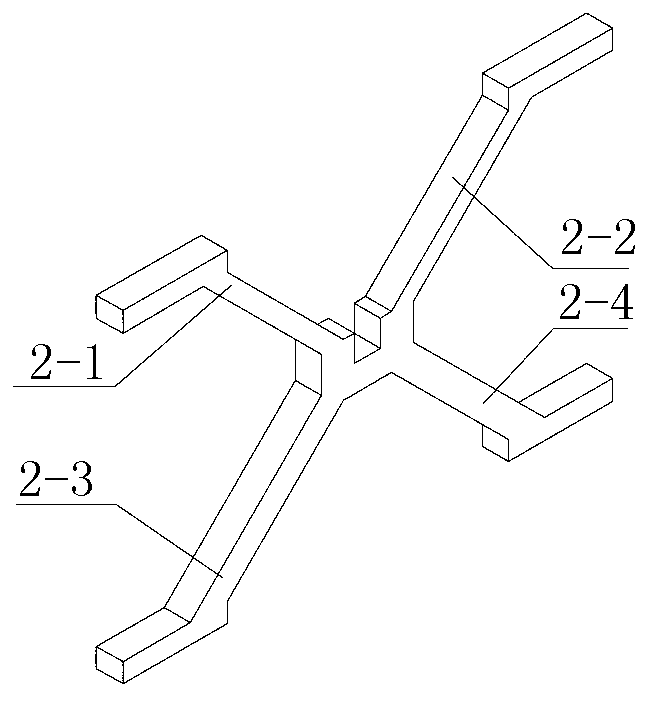

[0020] Specific implementation mode three: combination figure 2 Explain that each 'X'-shaped unit 2 in this embodiment is composed of the first rod 2-1 and the second rod 2-2 at the upper part and the third rod 2-3 and the fourth rod 2-4 at the lower part, The first bar 2-1 and the fourth bar 2-4 are arranged in parallel, the second bar 2-2 and the third bar 2-3 are arranged in parallel, the first bar 2-1, the second bar 2-2, the third bar 2 -3 and the width of the fourth bar 2-4 are equal, and the advantage of this structure is that the energy absorption capacity is strong. Other method steps are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com