Patents

Literature

82results about How to "No material waste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

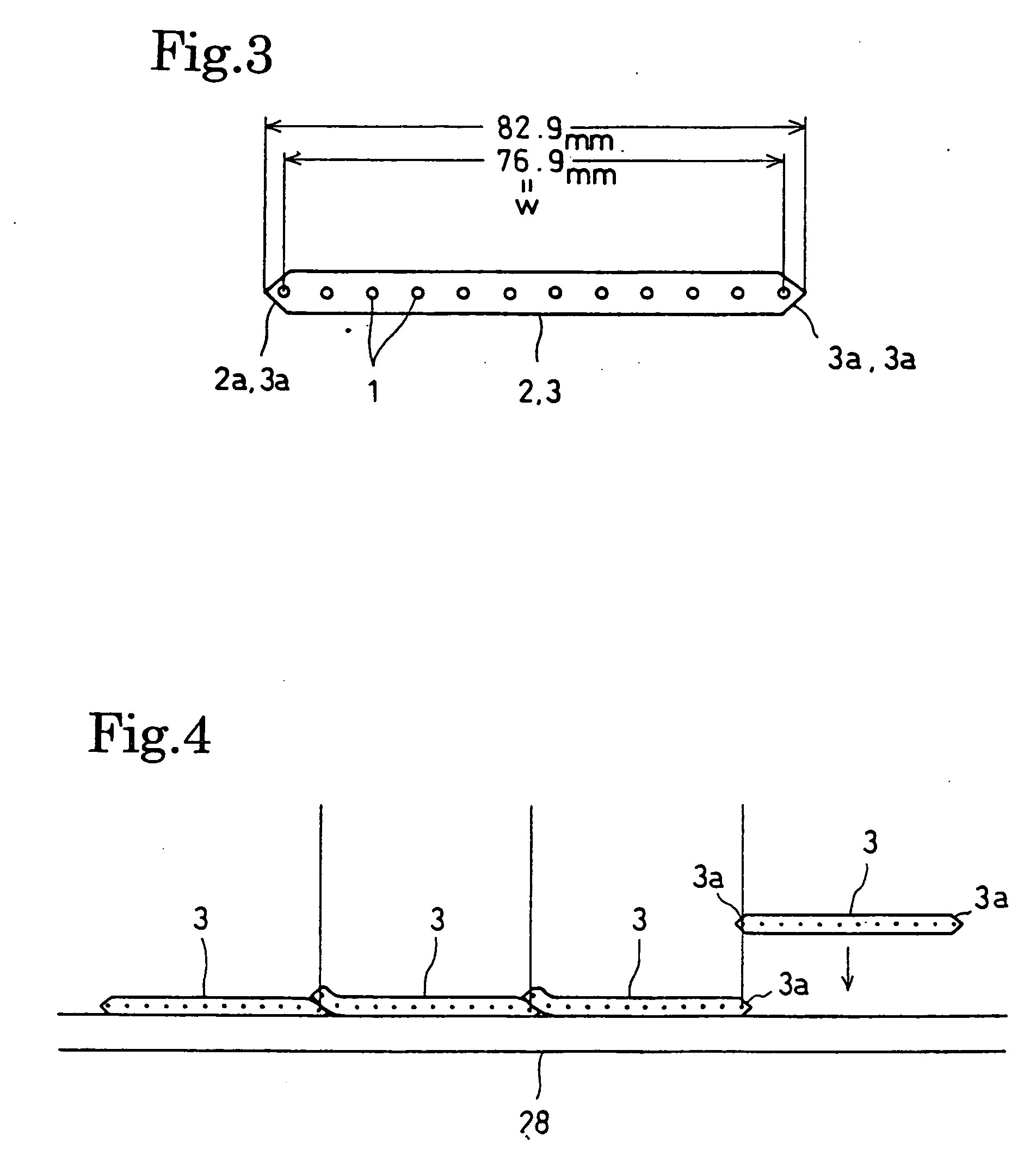

Lattice dressing

ActiveUS8680360B2Increase awarenessNo material wasteNon-adhesive dressingsPlastersWound dressingMedicine

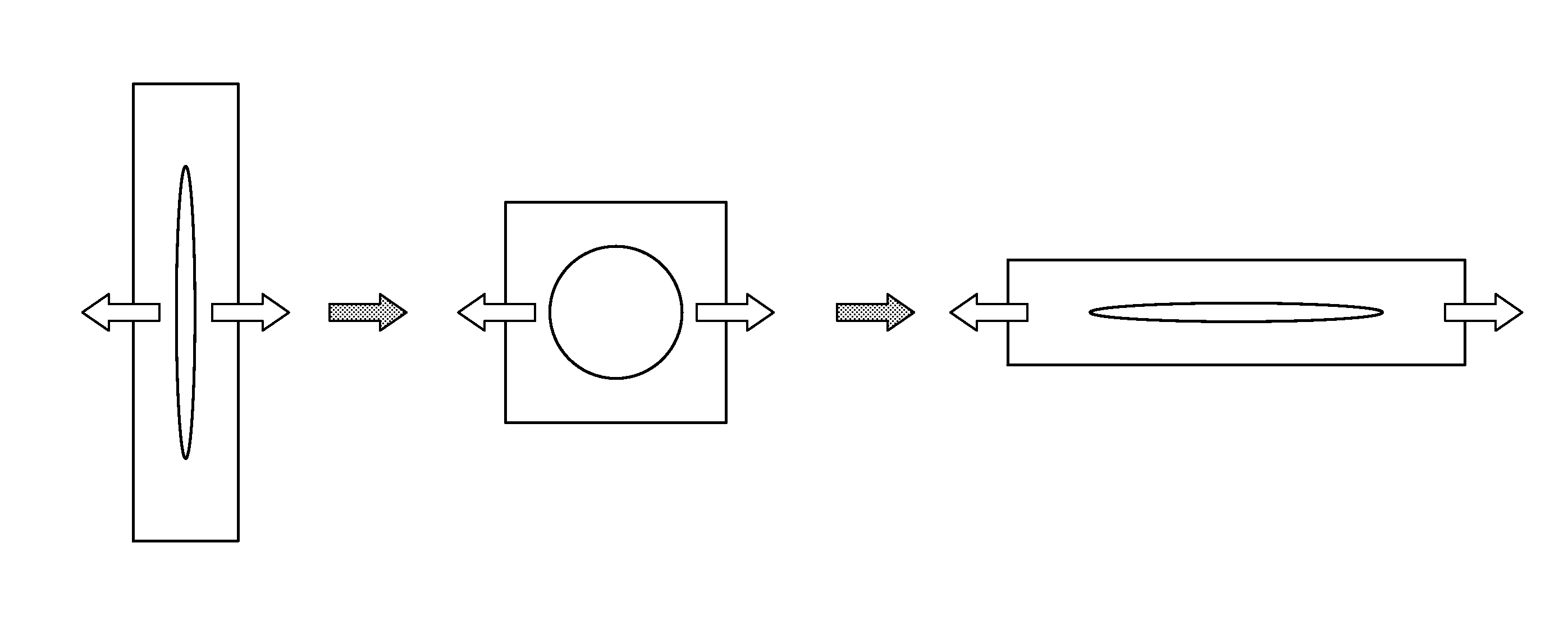

A wound dressing, a method of manufacturing a wound dressing, and in particular to a material for use as and in a wound dressing. A wound dressing can comprise a material movable between an initial conformation and an expanded conformation resulting from applying an extensive force to the material, such that removal of the extensive force can cause a contraction of the material toward a center of a wound. In addition, the wound dressing can comprise a retaining mechanism removably coupled to the material and configured to retain the material in the expanded conformation.

Owner:SMITH & NEPHEW INC

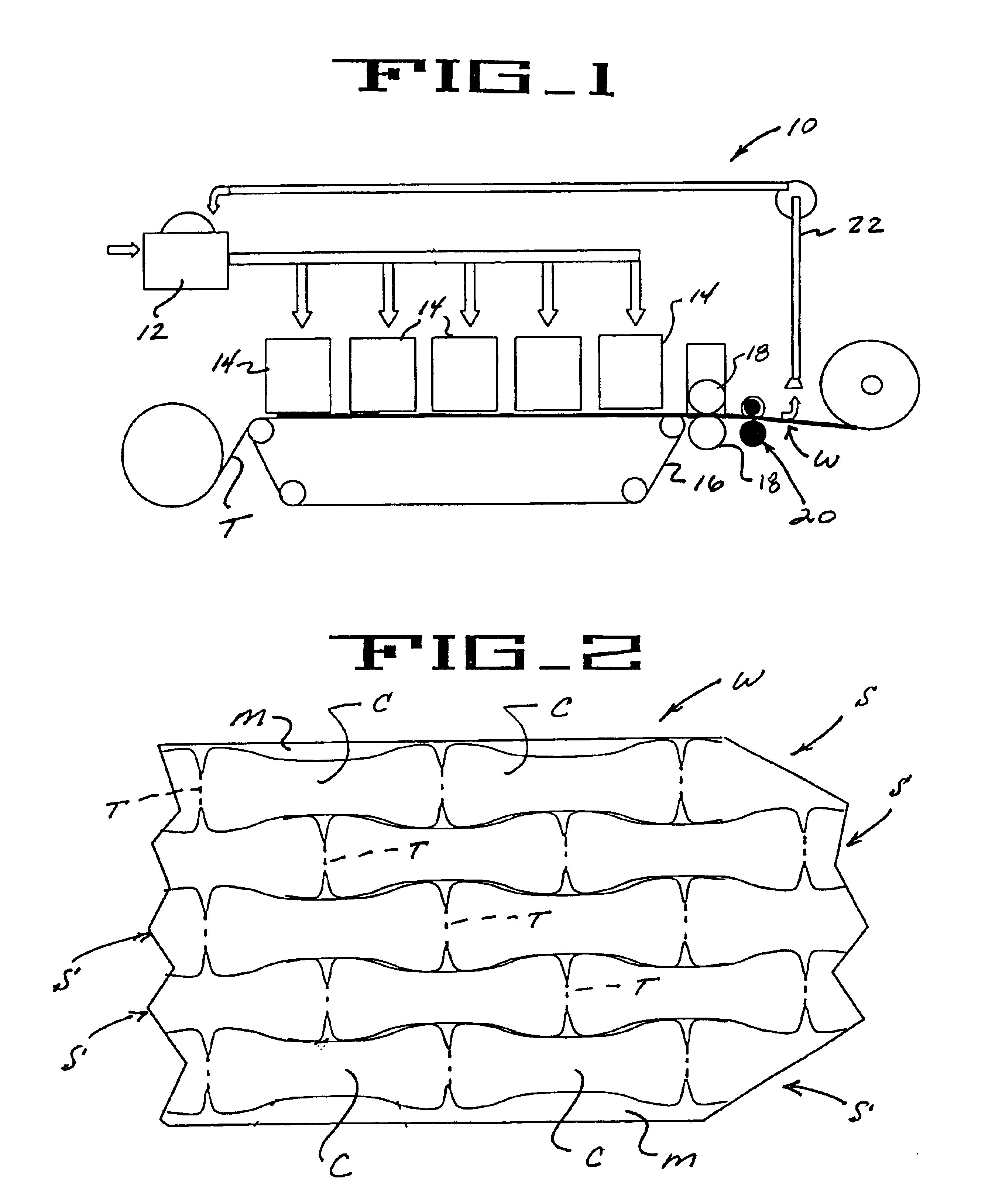

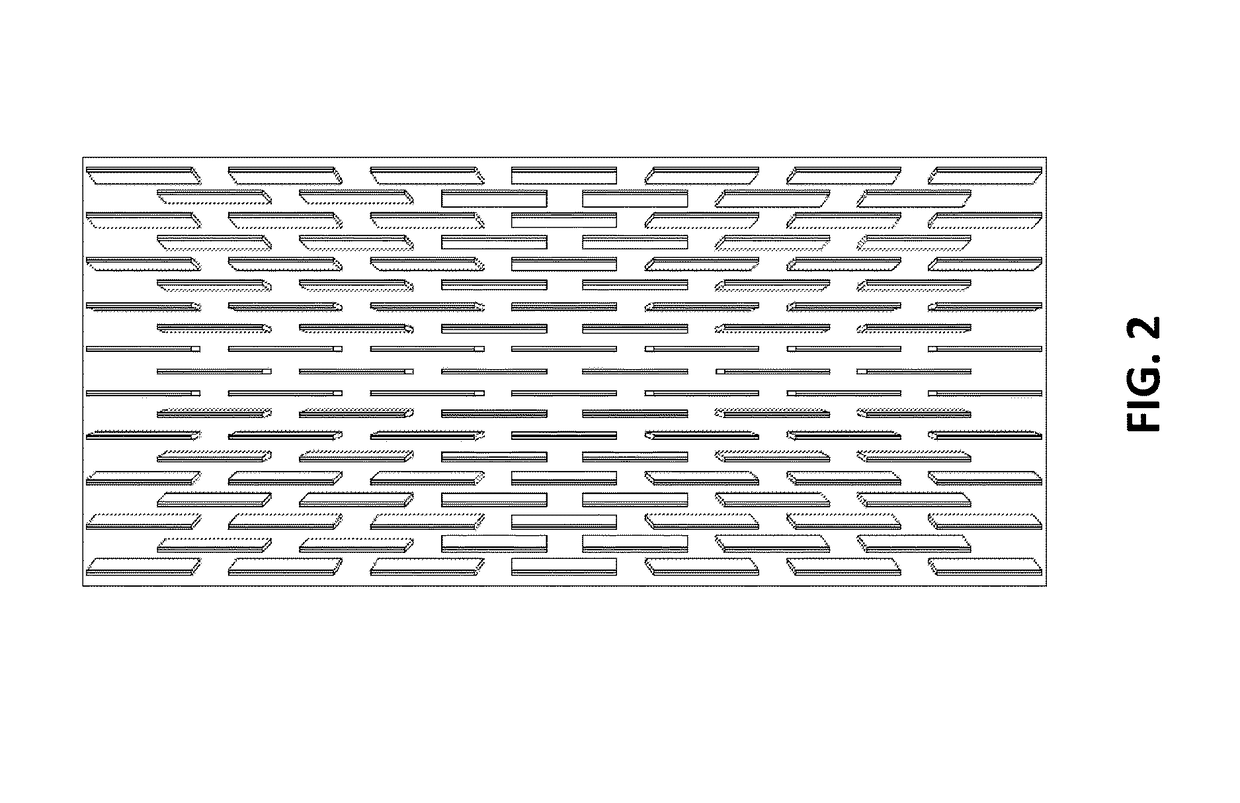

Method of making shaped components for disposable absorbent articles

InactiveUS6913718B2Reduce amountReduce the amount requiredArtificial filament recoverySevering textilesEngineeringMechanical engineering

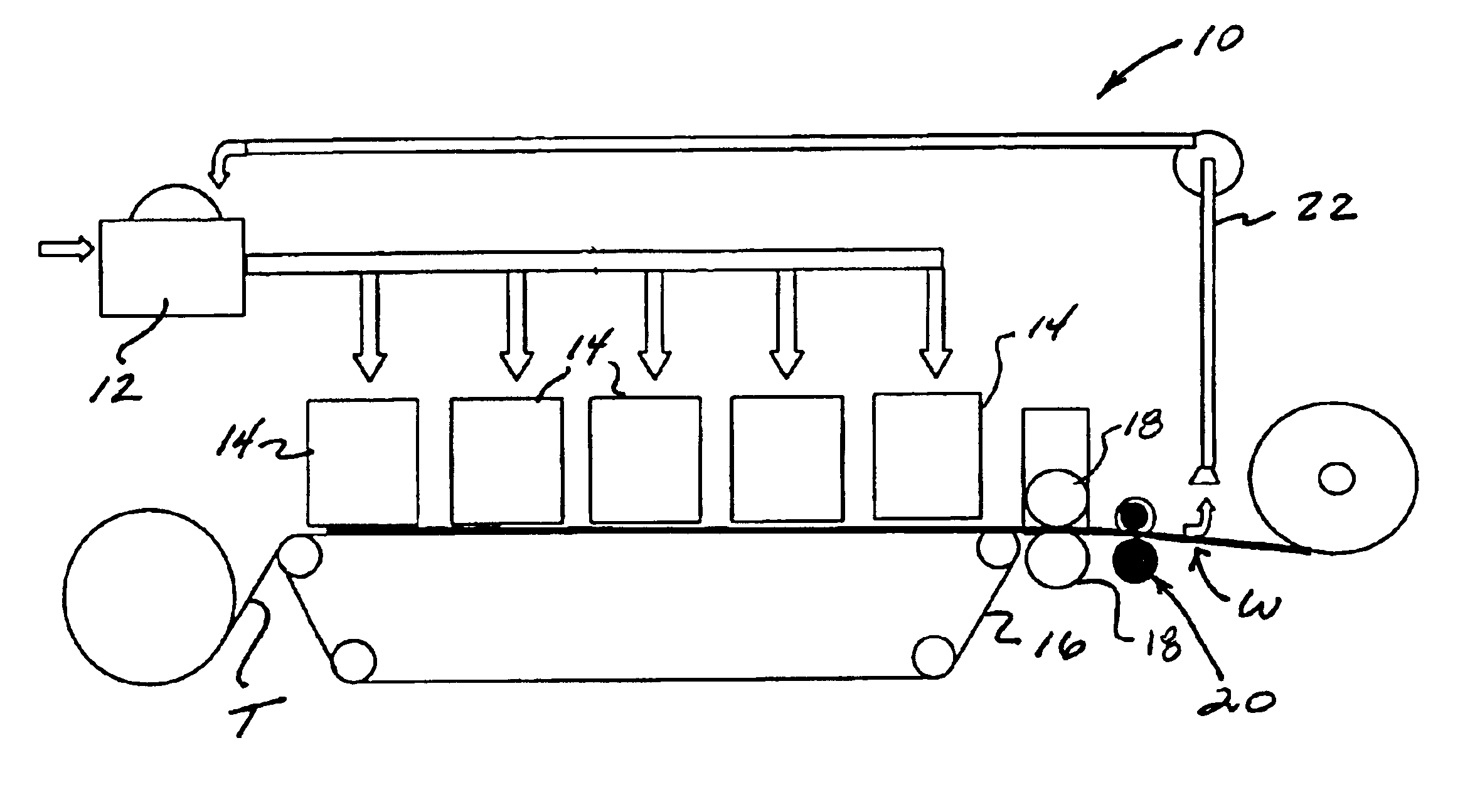

A method for formation of shaped components such as shaped absorbent cores, for disposable absorbent articles, contemplates that a relatively wide web of material be provided from which the components are cut. The web of material is longitudinally slit to form a plurality of subdivided webs each having shaped components arranged in serial relationship. The shaped components of adjacent ones of the subdivided webs are nested with each other, that is, a line extending longitudinally of the web extends through the components of adjacent subdivided webs. Efficient formation is facilitated by collecting the marginal portions of the web of material, and at least partially recycling the collected portions for formation of the wide web.

Owner:EAM

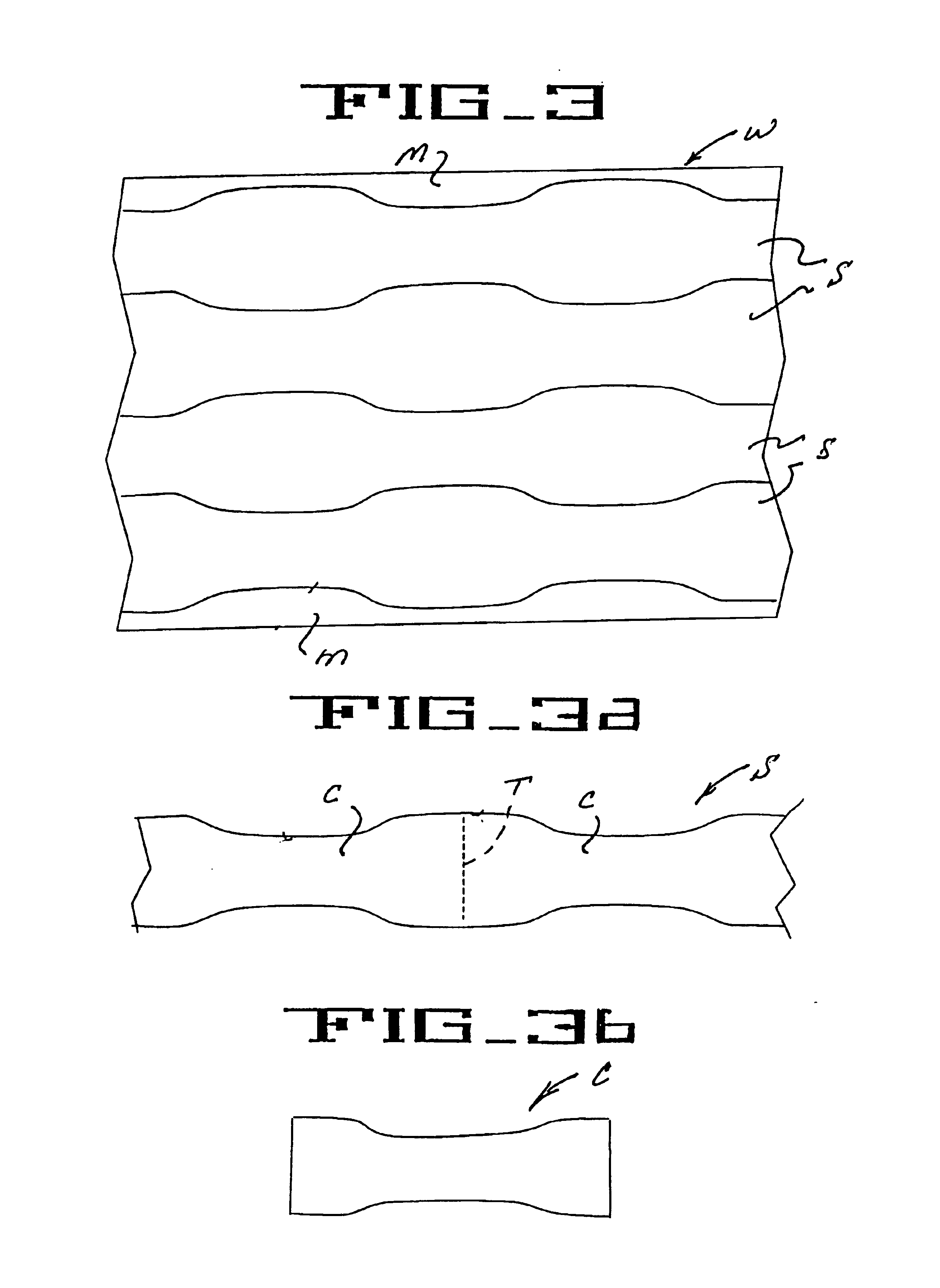

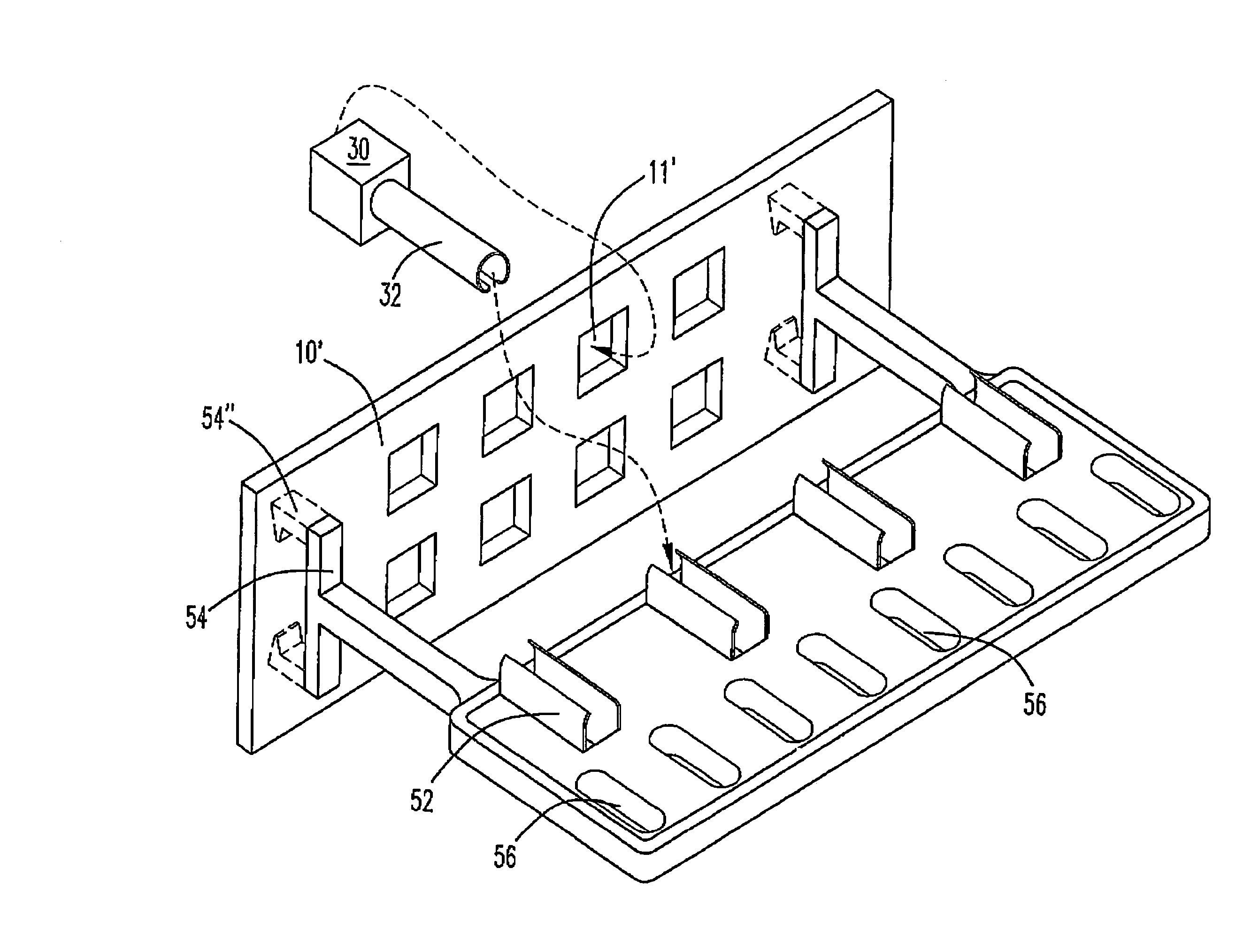

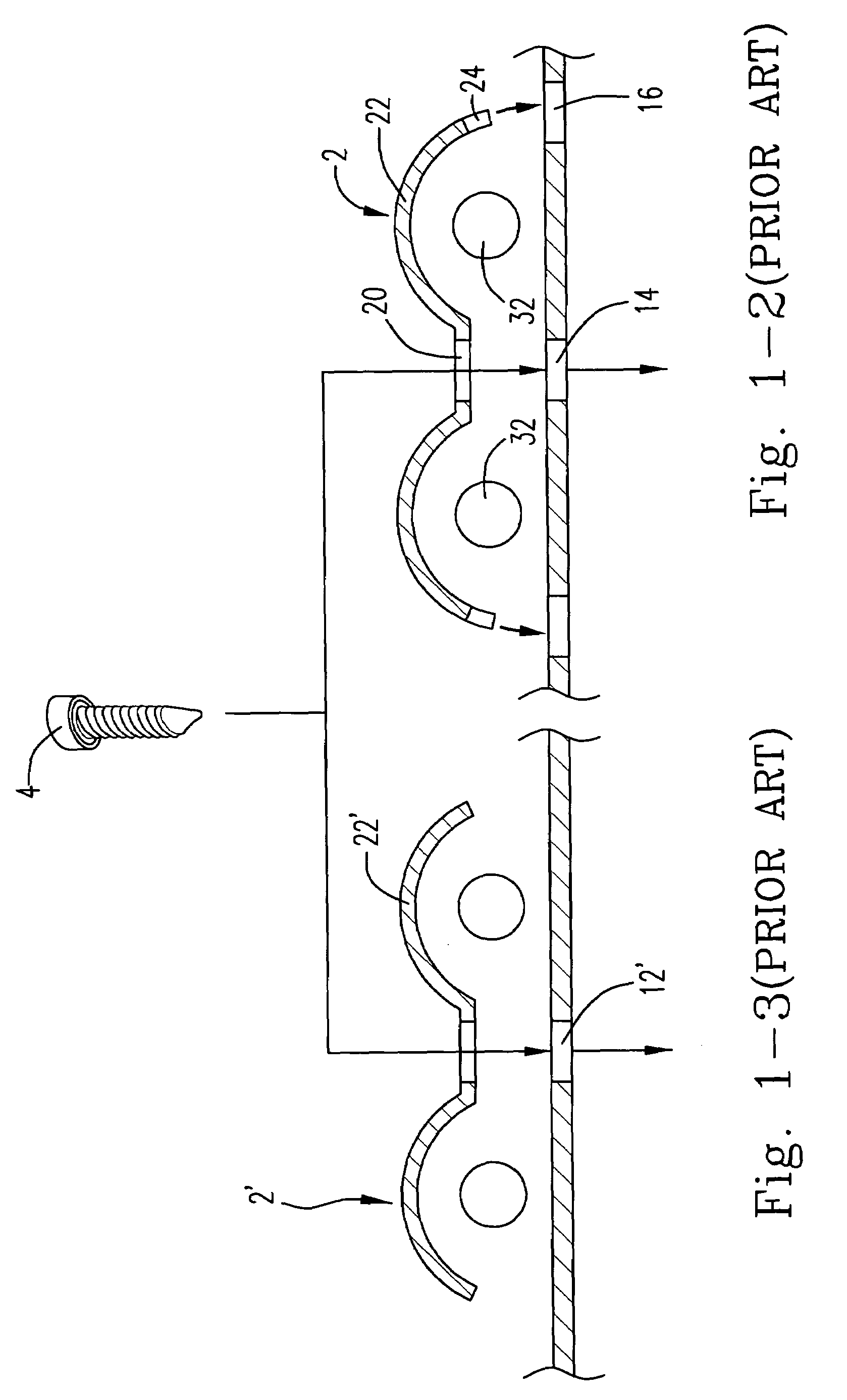

Cable manager

ActiveUS7077688B2Save resourcesShorten the timePipe supportsRelieving strain on wire connectionEngineeringCable management

Owner:PENG YUAN HUEI

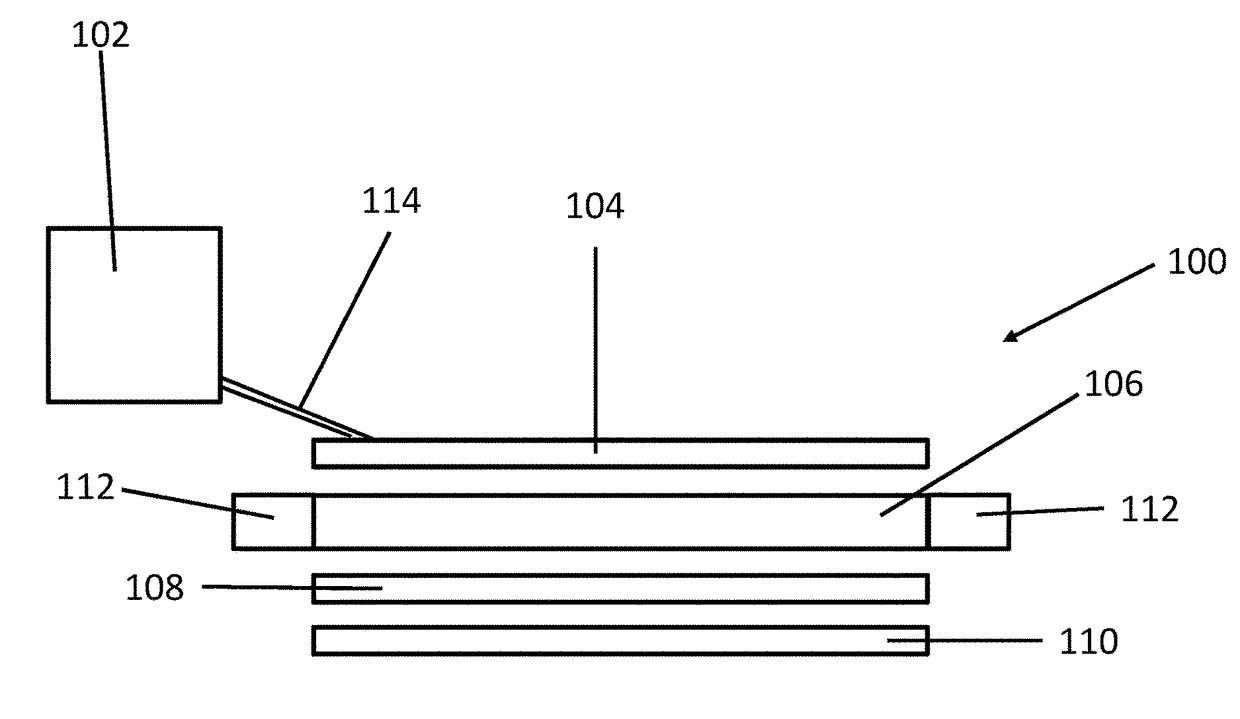

Wound dressing

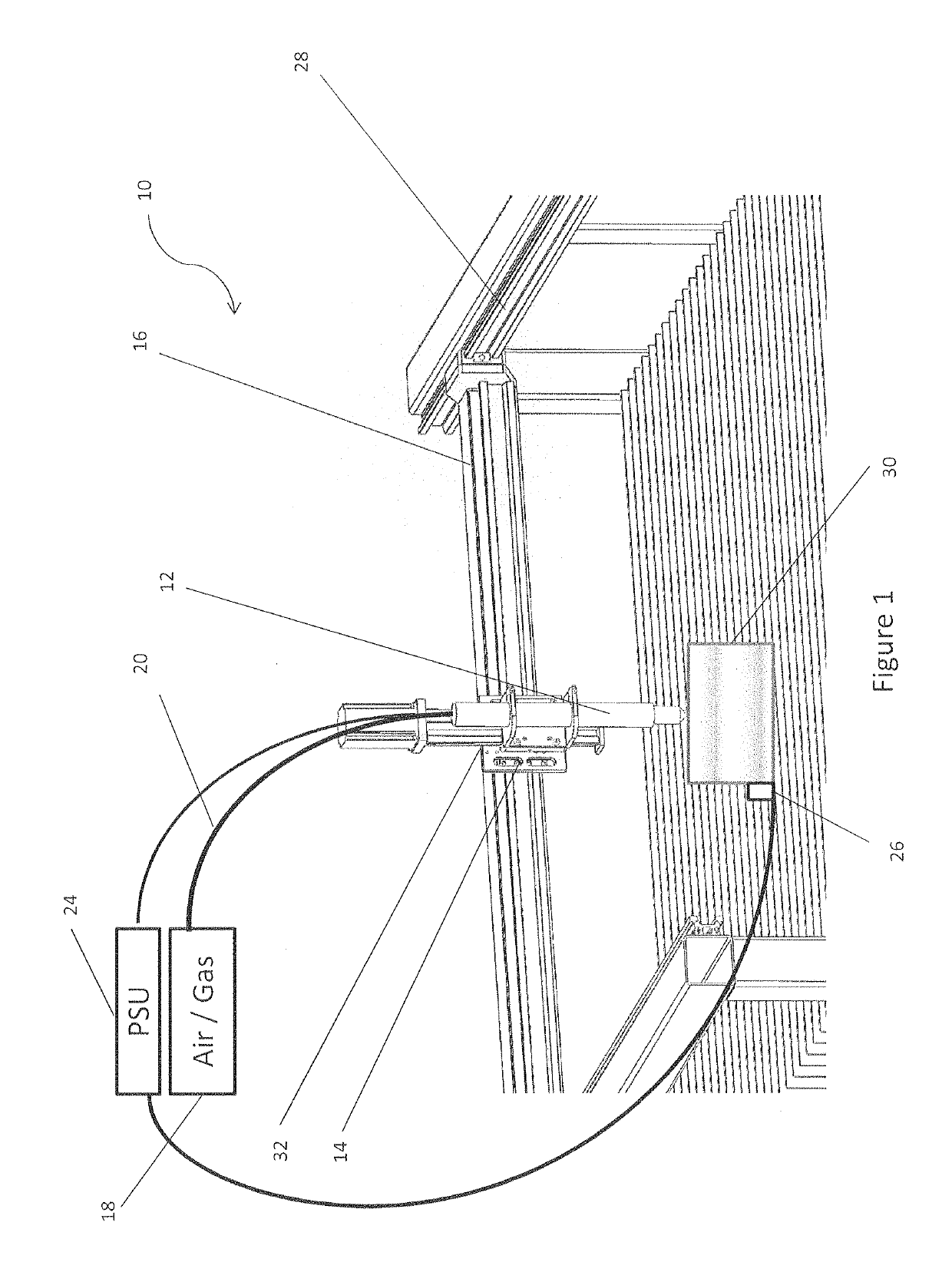

ActiveUS9820888B2Increase awarenessNo material wasteNon-adhesive dressingsWound dressingBiomedical engineering

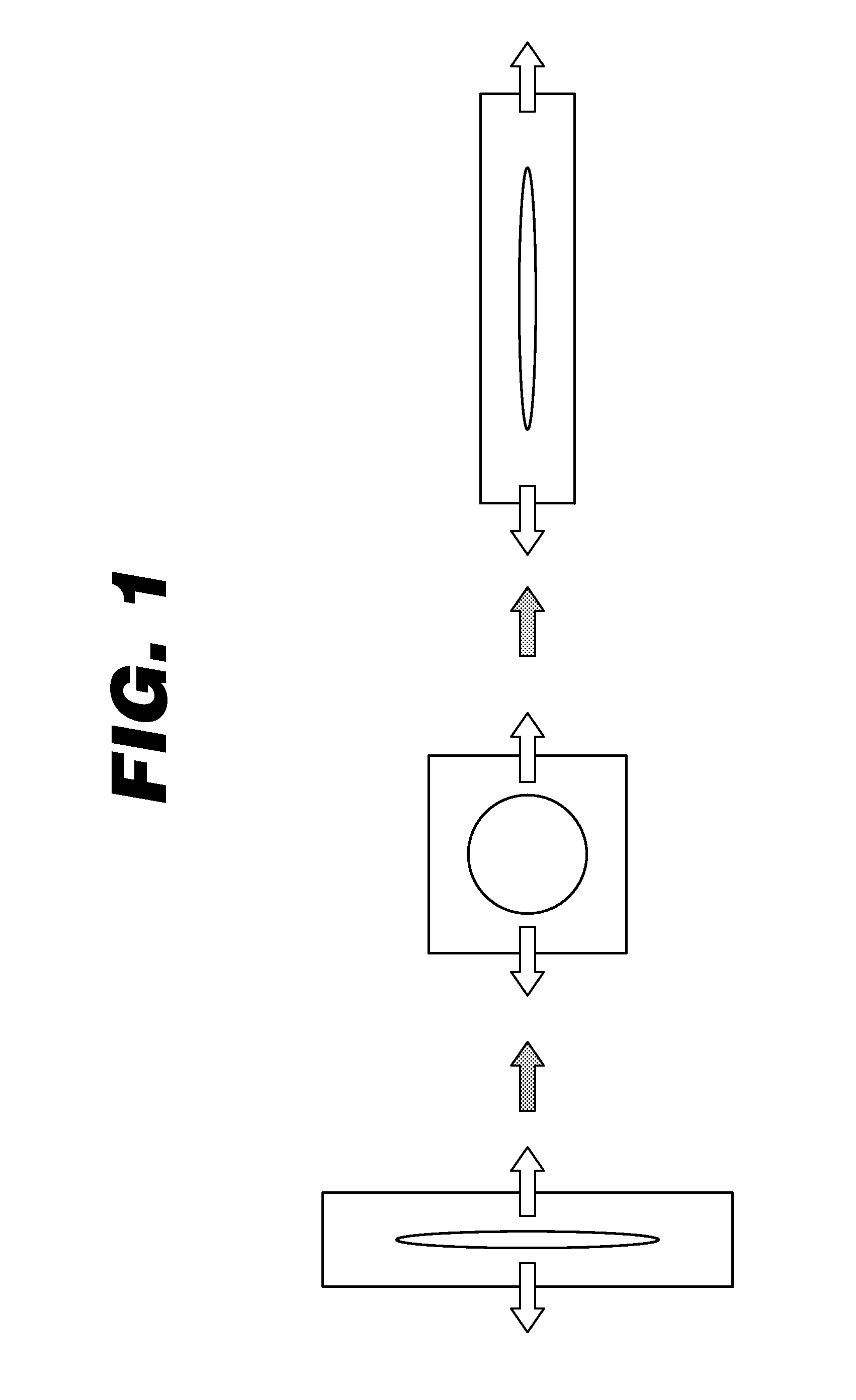

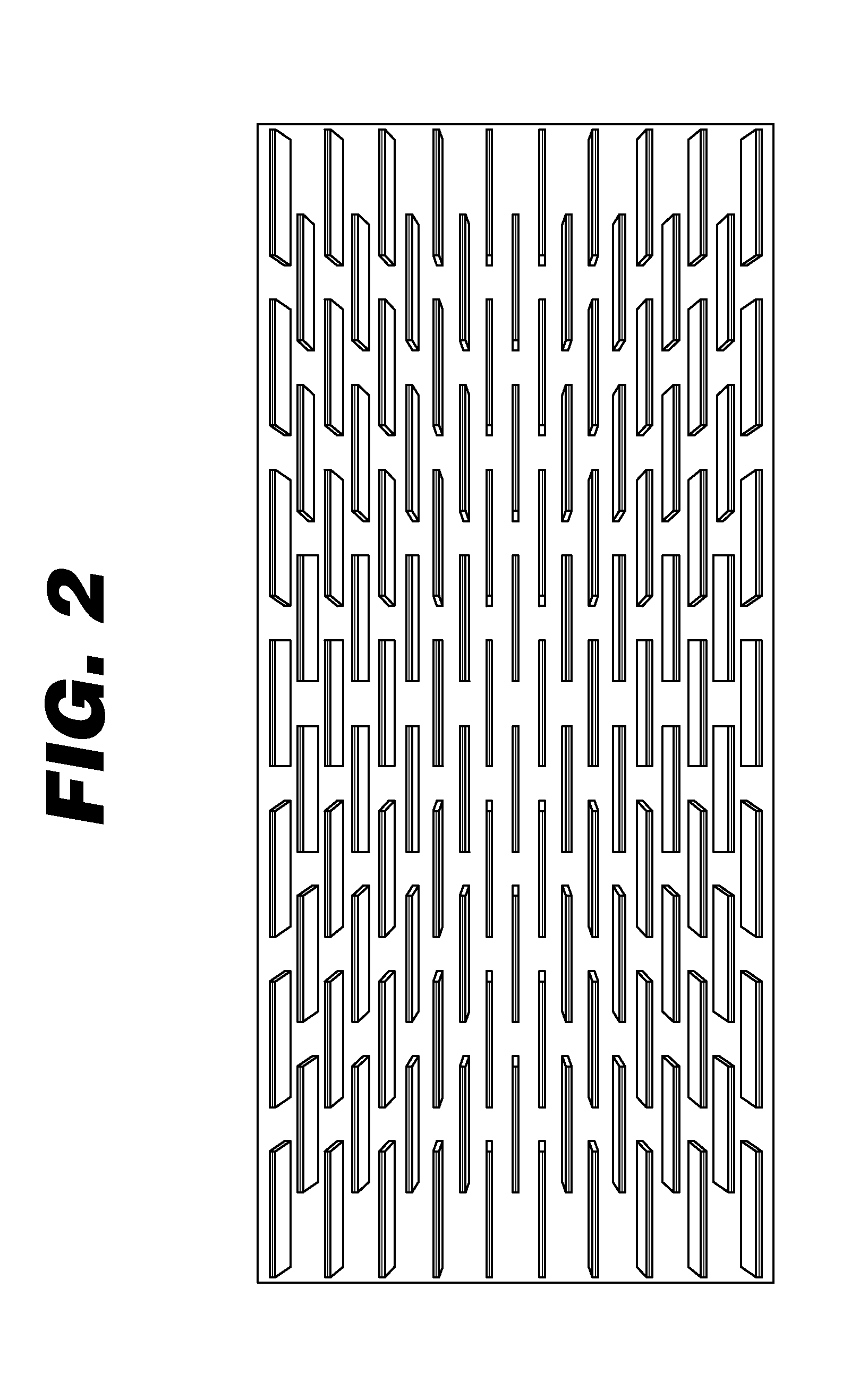

Embodiments disclosed within herein relate to a wound dressing, suitable for use in negative pressure wound therapy, comprising a body of porous material, the body of porous material comprising a plurality of cuts which provide regions of flexibility within the body. Further embodiments relate to methods of manufacturing and method of use of such wound dressings. In addition, the wound dressing can comprise a retaining mechanism removably coupled to the material and configured to retain the material in the expanded conformation.

Owner:VITESCO TECH USA LLC +1

Vehicular cleaning concentrate

ActiveUS7318871B2No material wasteOrganic detergent compounding agentsNon-ionic surface-active compoundsActive agentPhysical chemistry

The present invention relates generally to compositions, methods of use and kits for vehicular cleaning employing a cleaning concentrate containing at least one surfactant and at least one rheology modifier, optionally a solvent and / or optionally an alkalinity source, that exhibits a Vertical Cling parameter of between 1 and about 7 at a temperature of about 25° C. on soiled surfaces to which the compositions are applied.

Owner:ENERGIZER AUTO INC

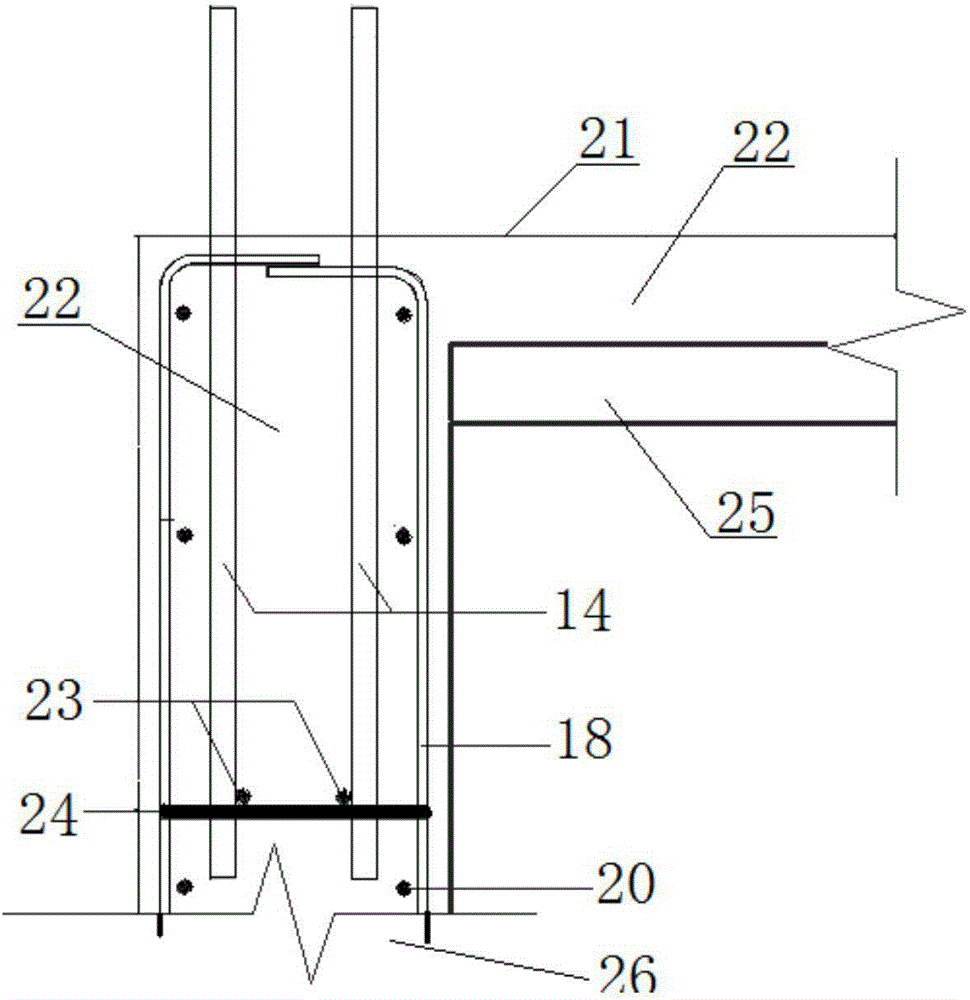

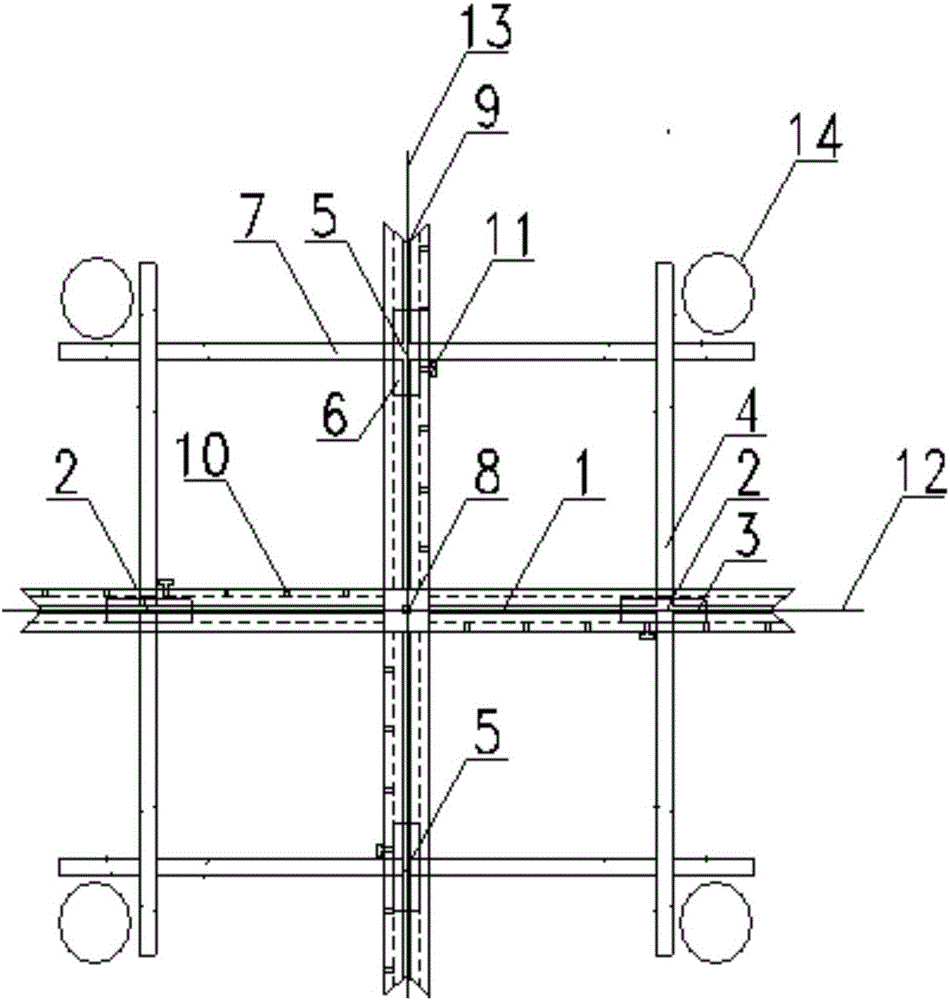

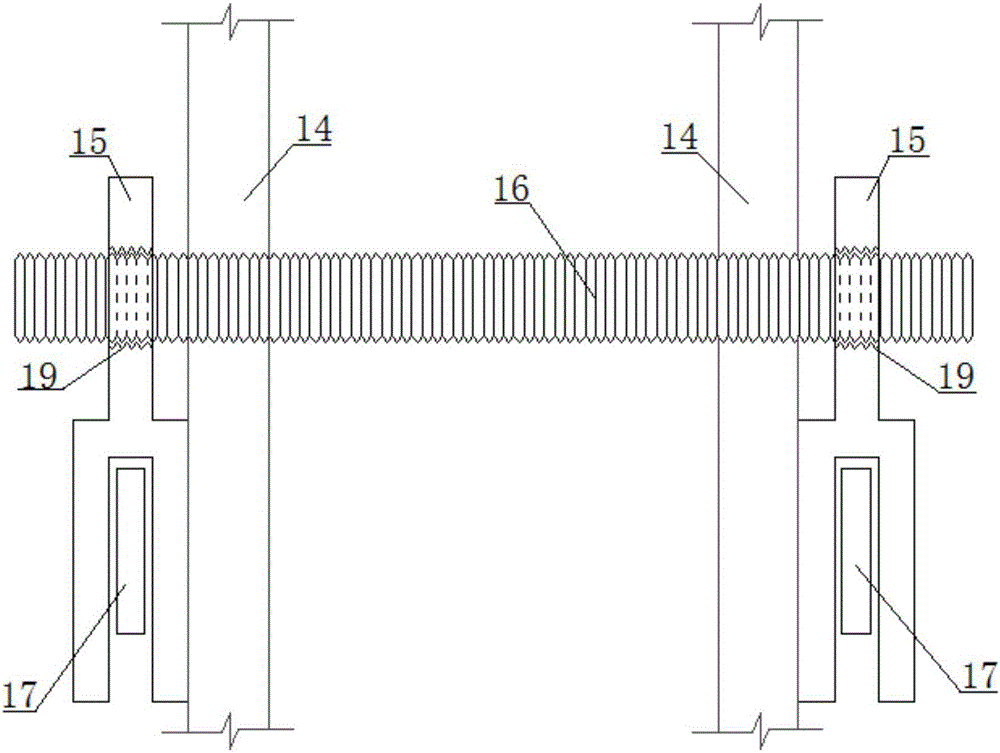

Positioning and reinforcing system and method for assembly type building cast-in-place connection layer reserved reinforcing steel bar

ActiveCN106639327ANo waste of materialSimple and efficient operationBuilding material handlingRebarShear wall

The invention discloses a positioning and reinforcing system and method for an assembly type building cast-in-place connection layer reserved reinforcing steel bar. The system comprises an axial positioning and detecting device and an anti-deflection reinforcing device. The axial positioning and detecting device is used for detecting and positioning the reserved reinforcing steel bar before casting, and the anti-deflection reinforcing device is used for reinforcing the positioned reserved reinforcing steel bar and preventing the reserved reinforcing steel bar from deflecting and inclining in the casting process. Positioning precision of the reserved reinforcing steel bar and non-deflection during concrete casting are guaranteed, cyclic and repeated use can be achieved, energy conservation and environmental protection are achieved, materials are not wasted, connection modes are all physical connection, operation is easy and quick, subsequent installation of a pre-cast shear wall is benefited, time for hoisting the wall in place is shortened, installation precision of the wall is improved, the installation quality is guaranteed, the construction cost is effectively reduced, and the construction period is shortened.

Owner:CHINA FIRST METALLURGICAL GROUP

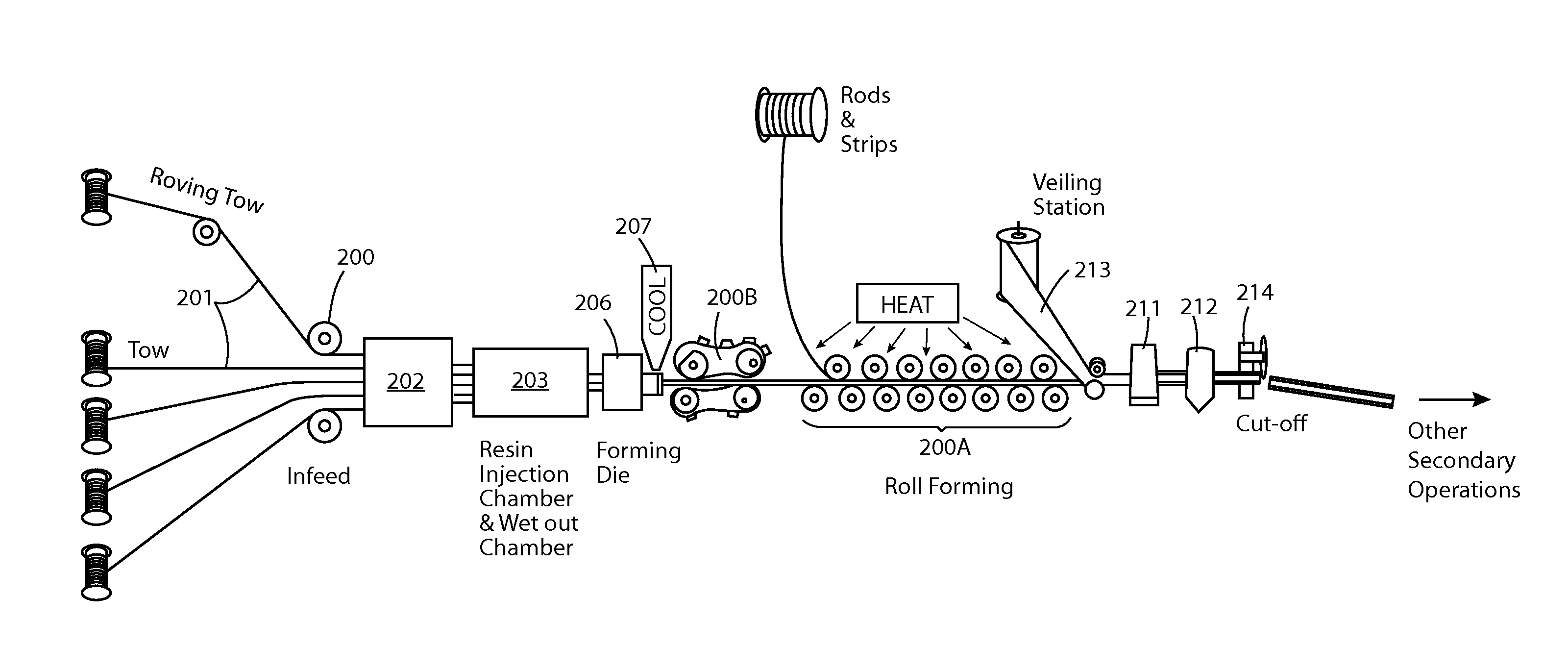

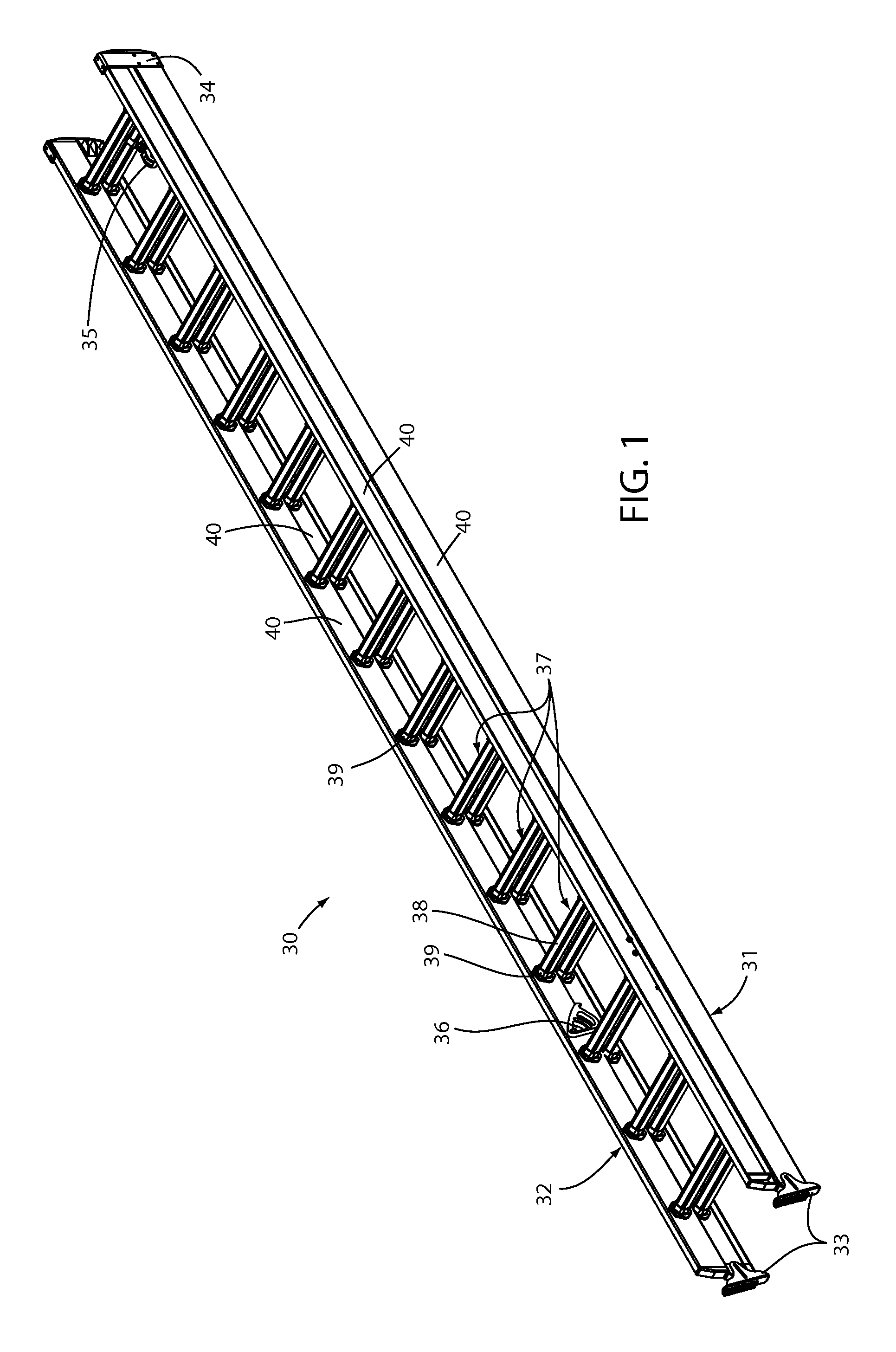

Thermoplastic pultruded process and related products

InactiveUS20150376946A1Increase load strengthHigh strengthDecorative surface effectsDuplicating/marking methodsGlass fiberThermoplastic polyurethane

A pultrusion process comprises steps of: pulling a matrix of continuous reinforcement fibers through a wet-out chamber and forming die while injecting thermoplastic resin (e.g. thermoplastic polyurethane) into the wet-out chamber, and providing secondary stations that remove, reform, and / or add material downstream of the forming die using heat and pressure to form a final beam shape with integrally-formed features thereon. The reinforcement matrix is optimally glass fiber, but can include different types of reinforcements, including strands, bundles, mats, weavings, rods, and other reinforcements and combinations of reinforcements, each of which can be strategically located in the beam profile. The final beam includes intermittent or continuous specialized features integrated into the beam along its length, allowing reduction of material waste, reduced / minimized later assembly, and reduced total number of parts.

Owner:JERSHON

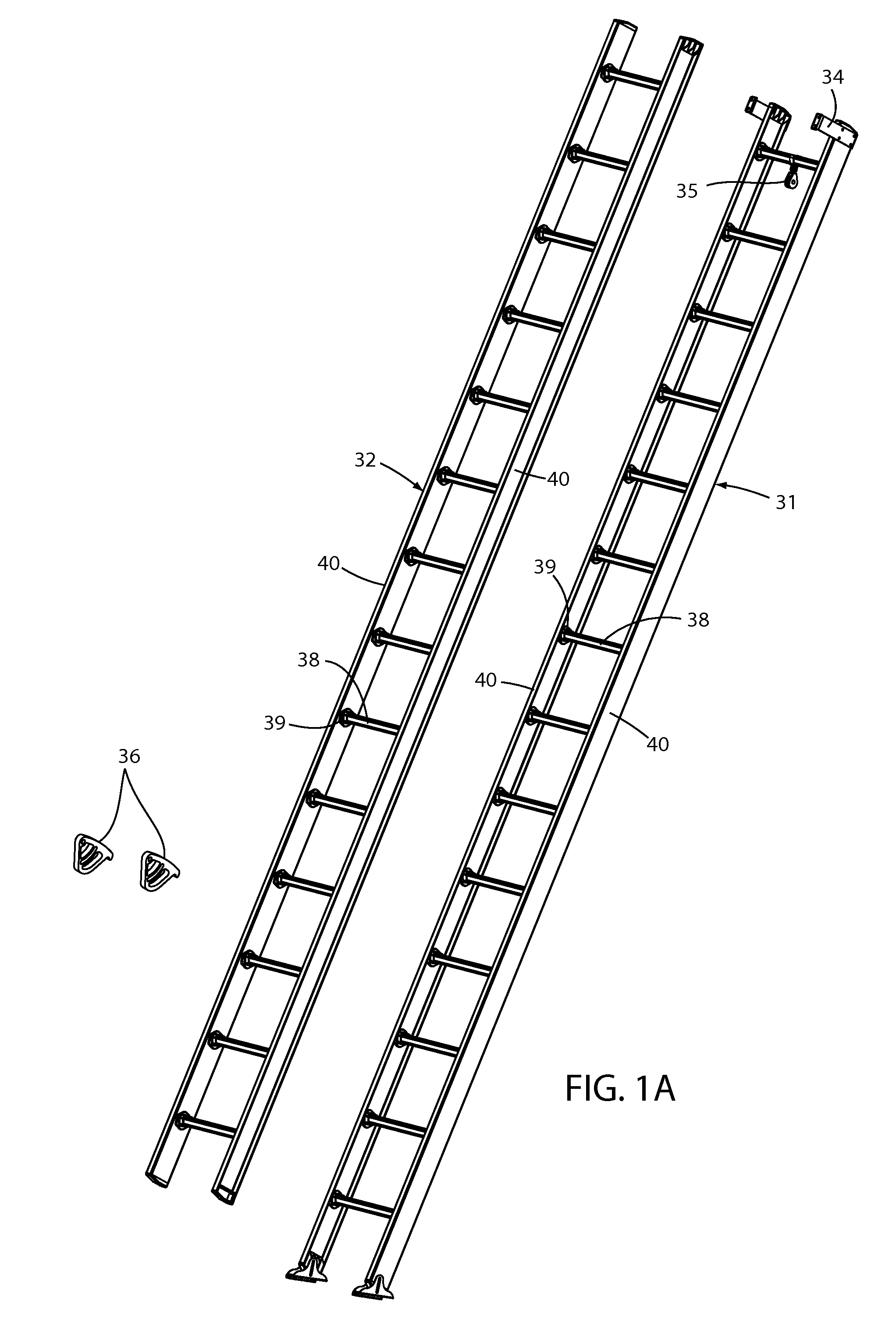

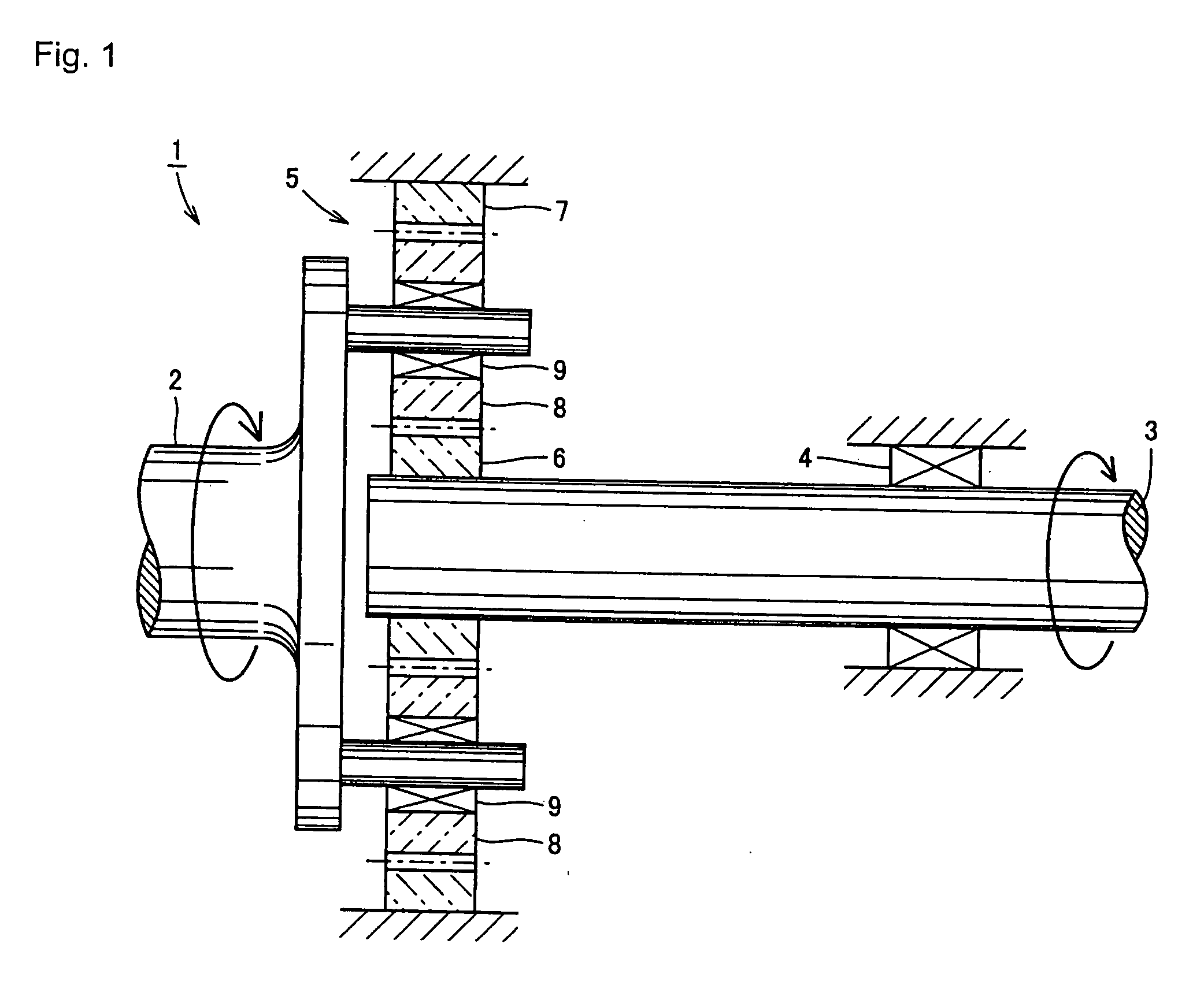

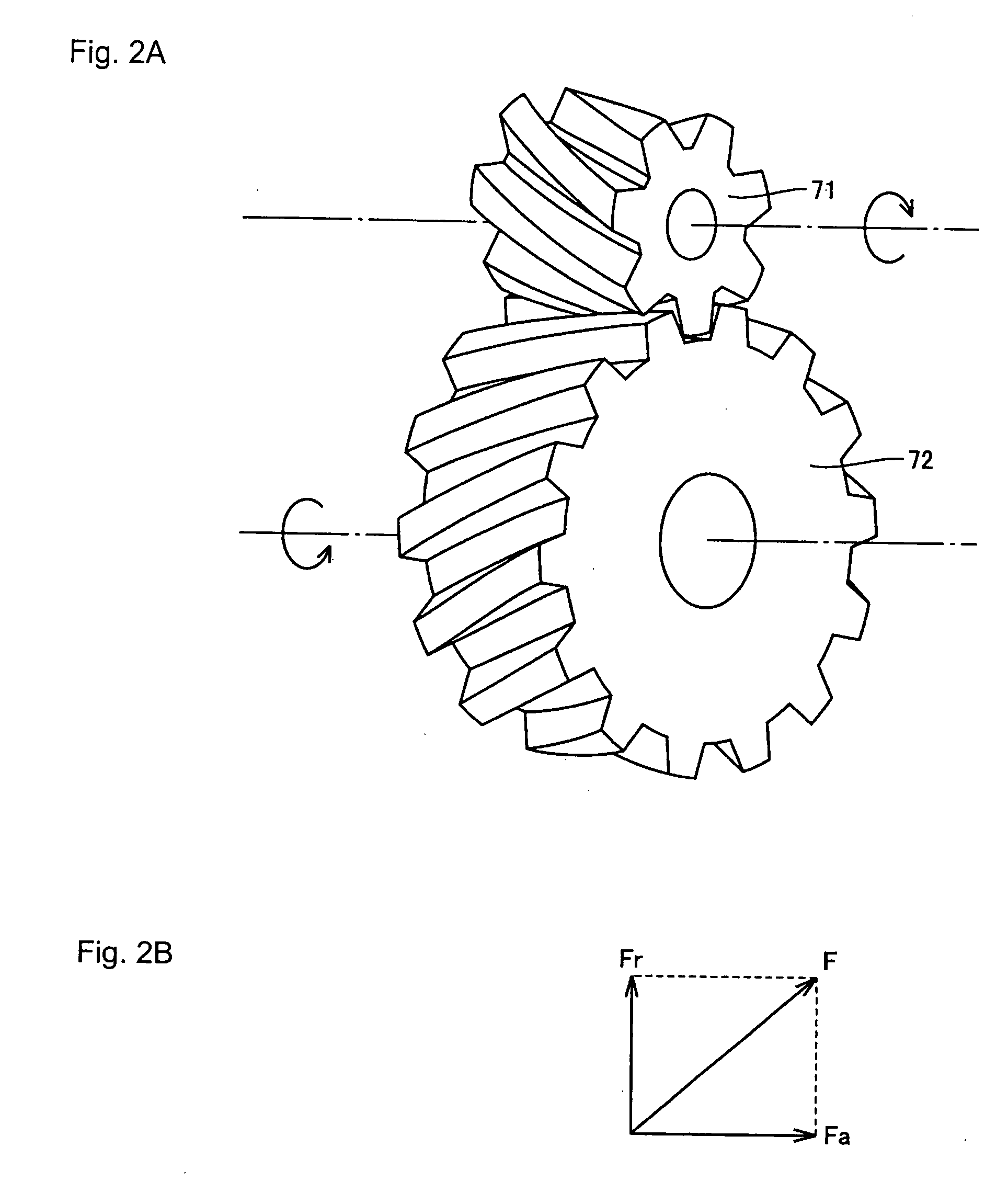

Helical Gear Supporting Structure, Speed Increaser for Wind Power Generator, and Vertical Shaft Supporting Structure

InactiveUS20080118344A1Improve reliabilityLong life-timeRoller bearingsWind motor controlRolling-element bearingEngineering

In a support structure supporting a shaft of a helical gear, a shaft of a speed increase for a wind power generator with a helical gear, or a vertical shaft by a double row rolling element, the double row rolling bearing is so formed that load capacities on the bearing in the right and left rows are different from each other so that the load capacity on the bearing in the row where the rolling bearing receives a large axial load can be increased.

Owner:NTN CORP

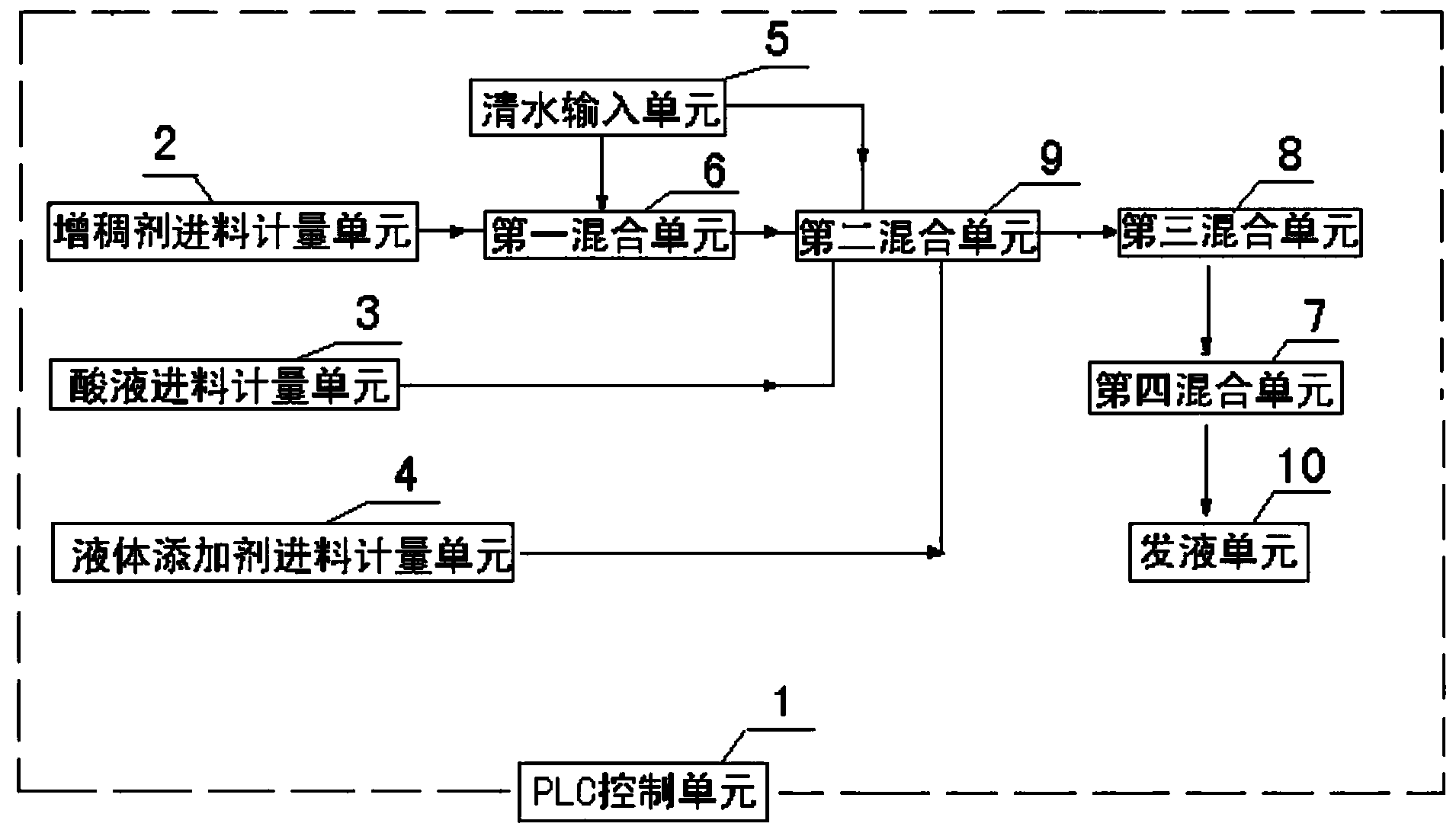

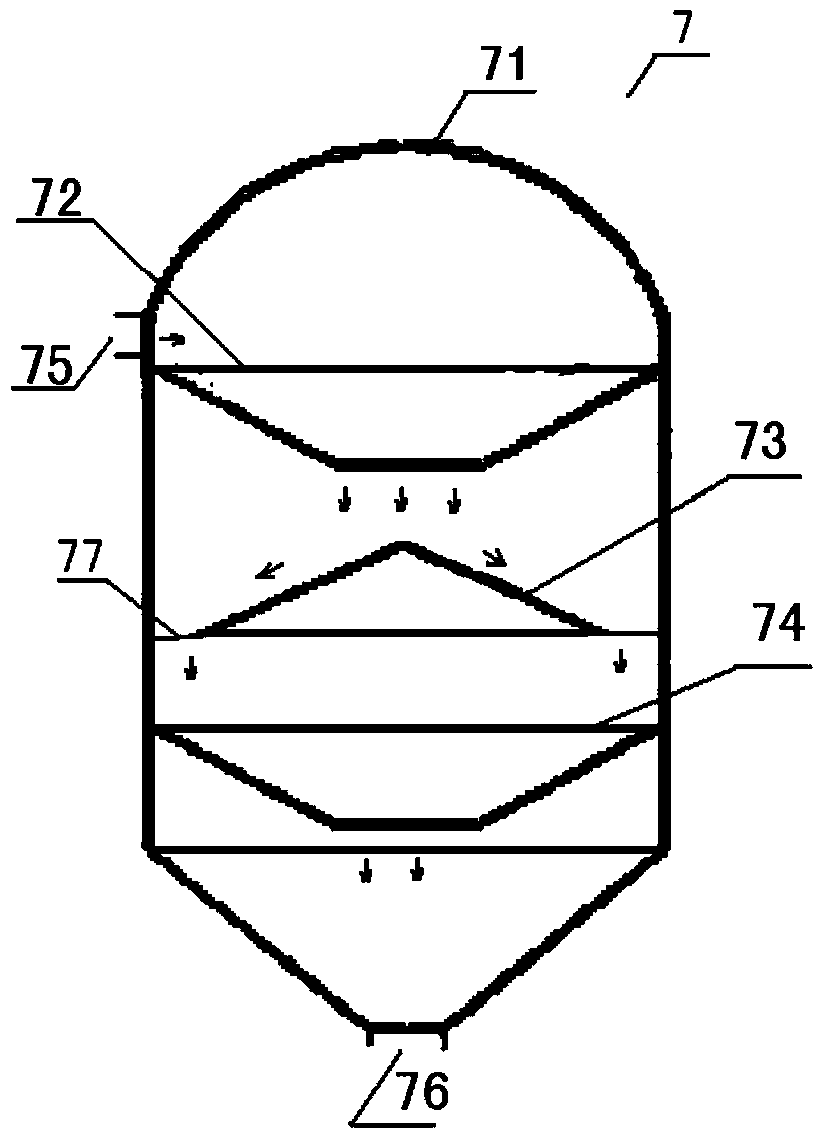

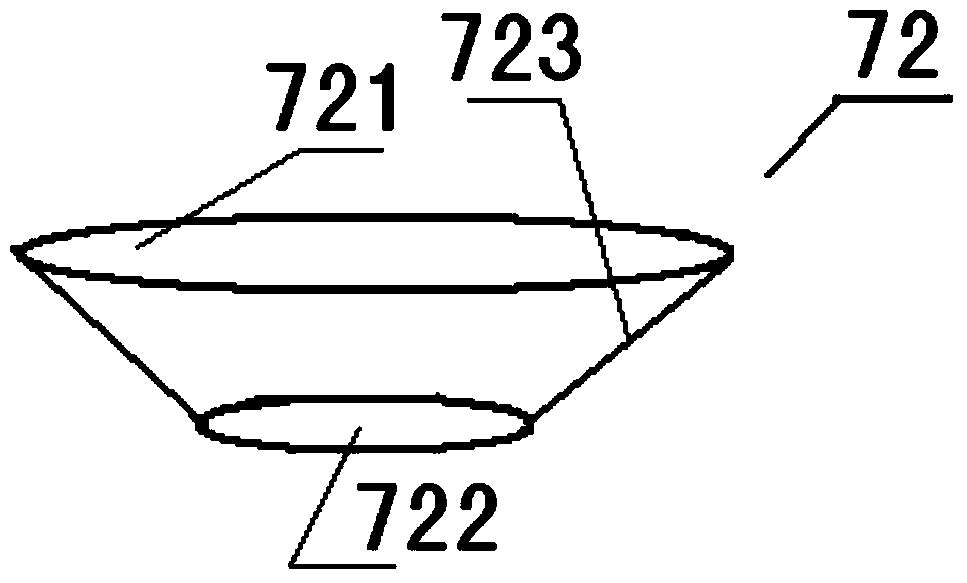

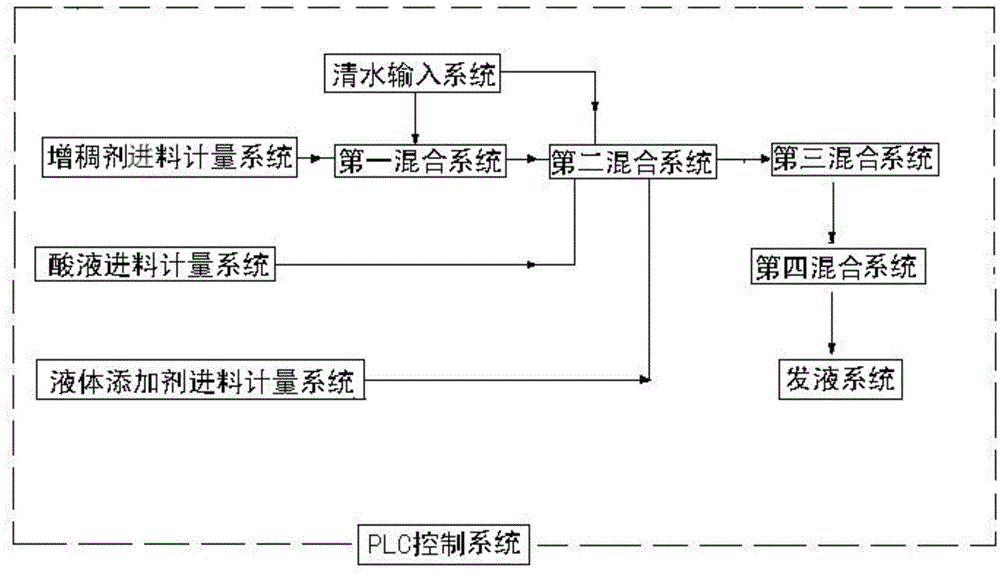

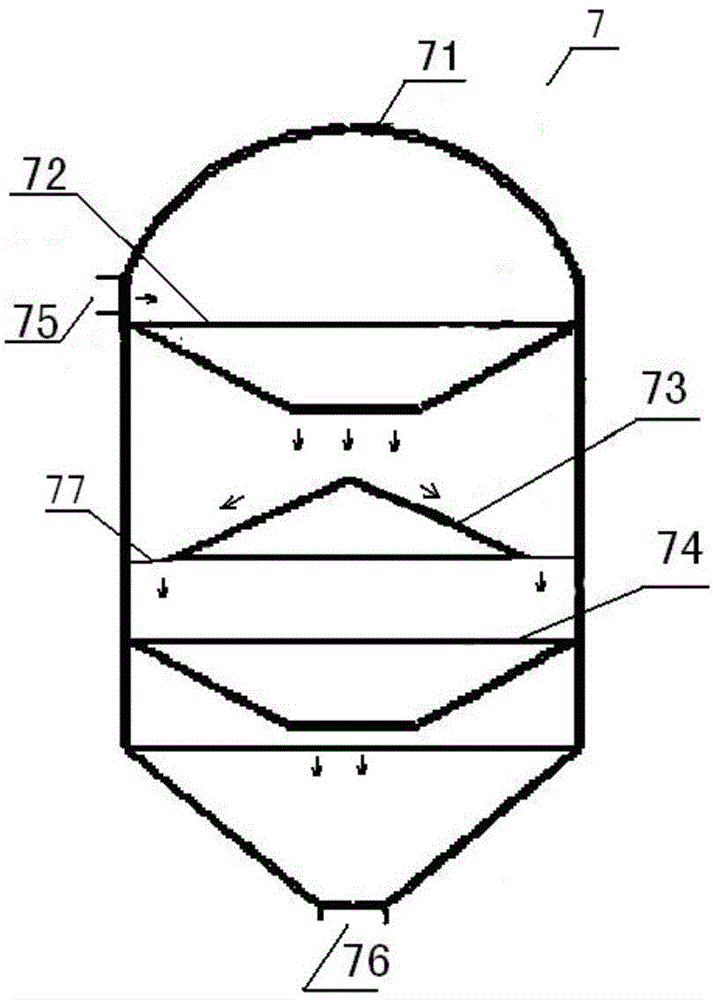

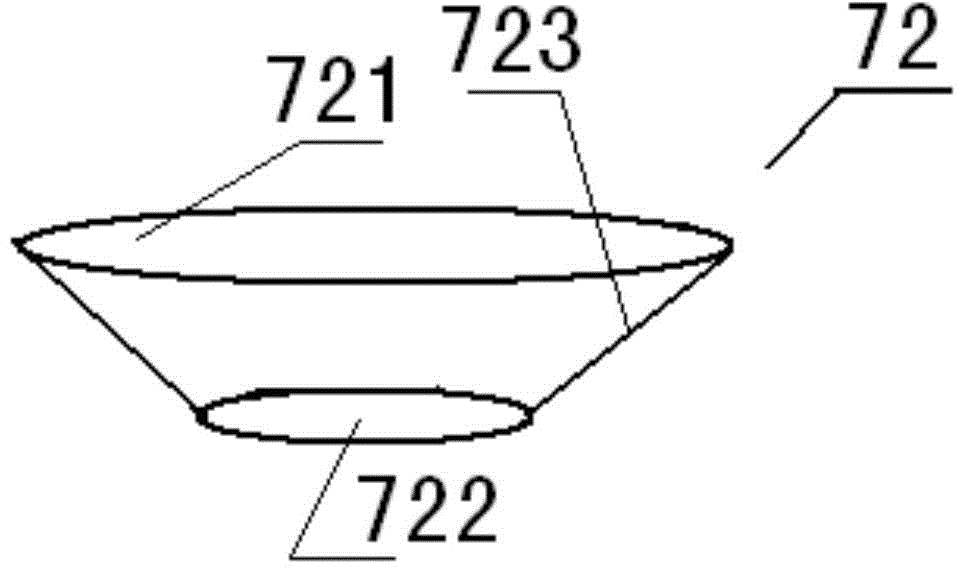

Acid fracturing liquid continuous blending supply device

ActiveCN103726821AUniform viscosityNo stratificationFlow mixersFluid removalAcid fracturingEnvironmental engineering

The invention discloses an acid fracturing liquid continuous blending supply device which comprises a clear water input unit, a first blending unit, a whole blending unit and a liquid sending unit. The clear water input unit is used for feeding clear water in a quantifying mode at a constant speed. The first blending unit is connected with the clear water input unit and is used for blending thickening agents and clear water from the clear water input unit, so that a thickening agent pre-blending solution is obtained. The whole blending unit is connected with the first blending unit and is used for blending the thickening agent pre-blending solution, acid liquid and various liquid additives, so that acid fracturing liquid is obtained. The liquid sending unit is connected with the whole blending unit and is used for discharging the acid fracturing liquid from the whole blending unit. According to the blending device, continuous blending supply of water, acid liquid, dry powder or pasty fluid and various liquid additives can be achieved, blending effect is good, blending is even, acid liquid quality is high, in addition, a large amount of manual cost is reduced through a continuous automatic acid preparing device, the requirement for an acid storage tank is lowered, construction liquid is saved, and equipment cost is saved.

Owner:BEIJING SHENZHOU ZHUOYUE GASOLINEEUM TECH

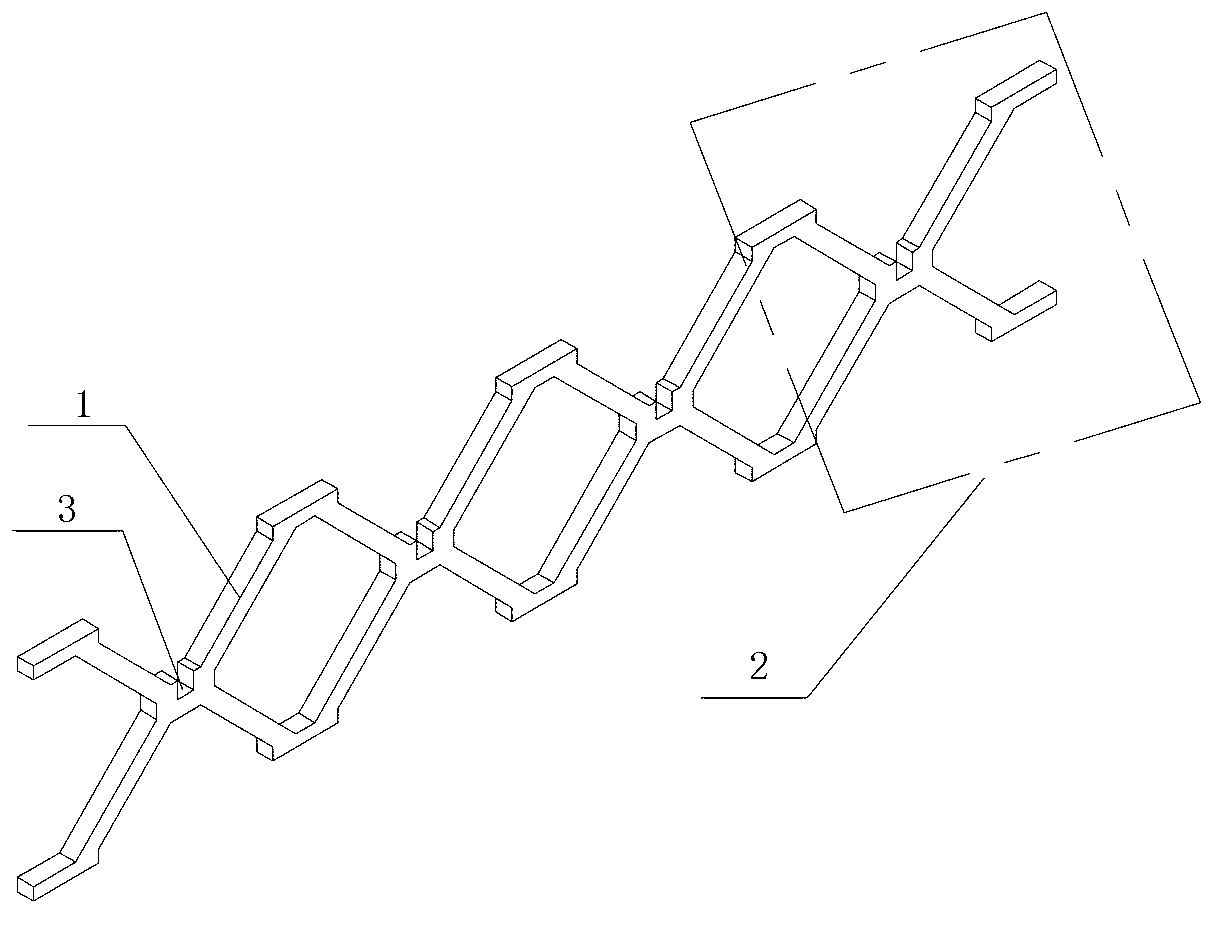

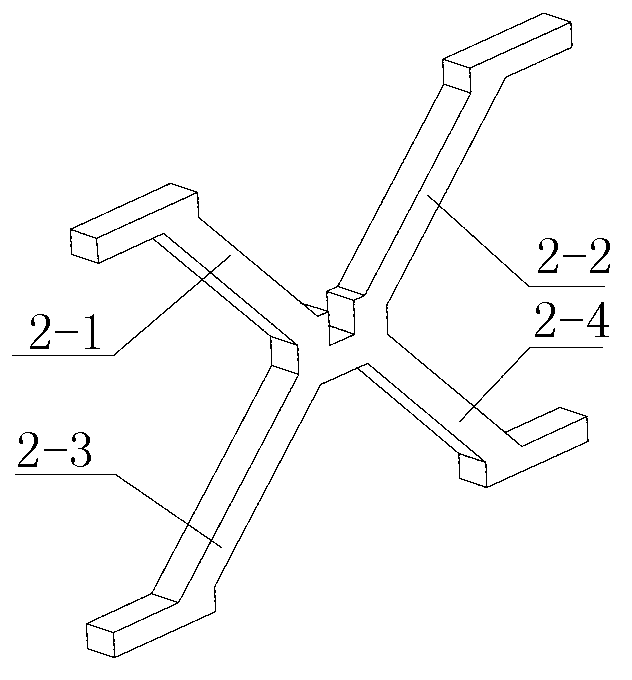

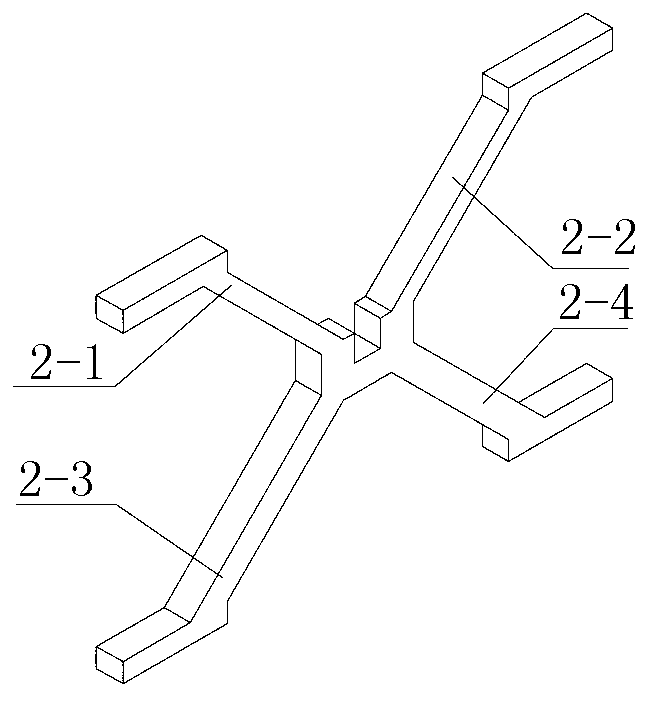

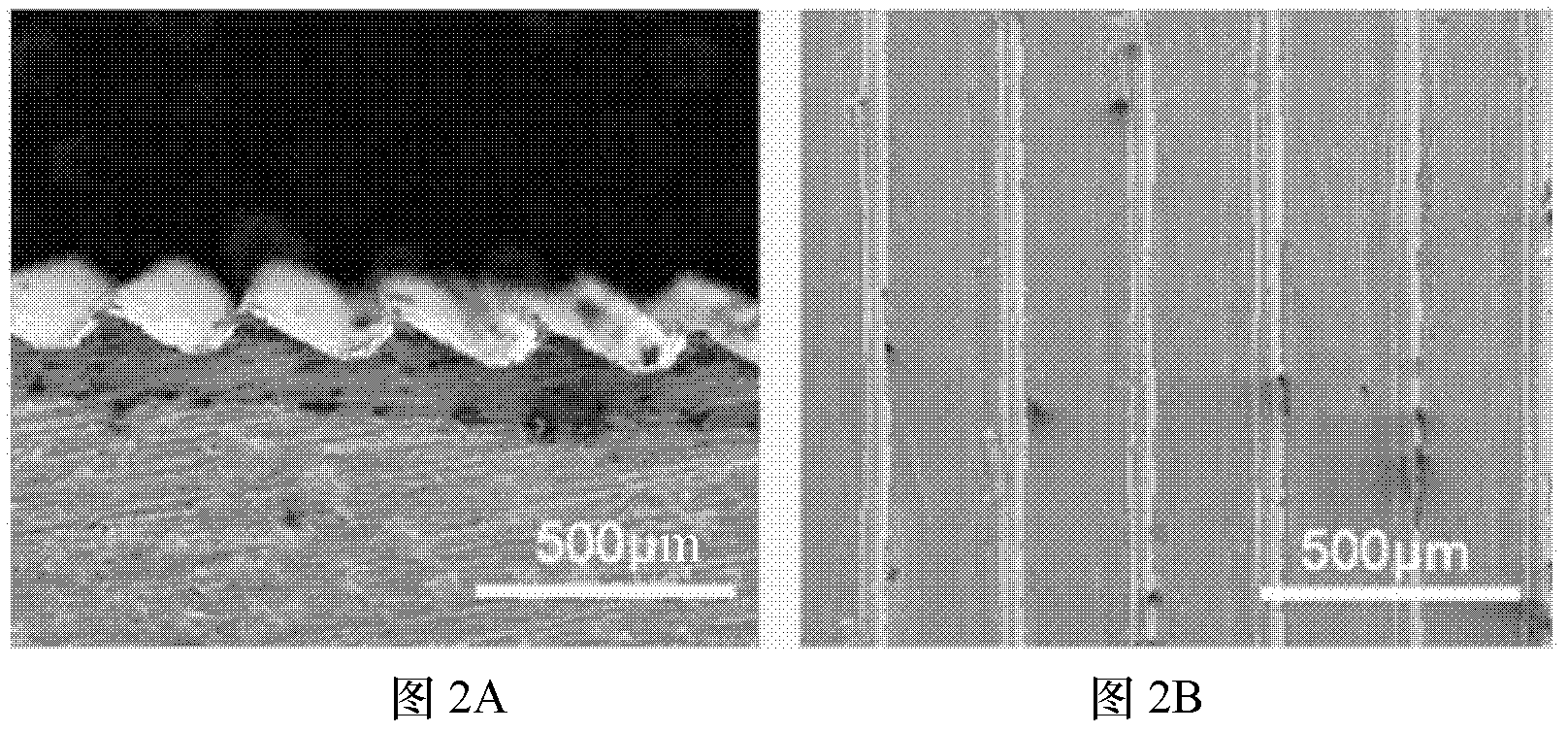

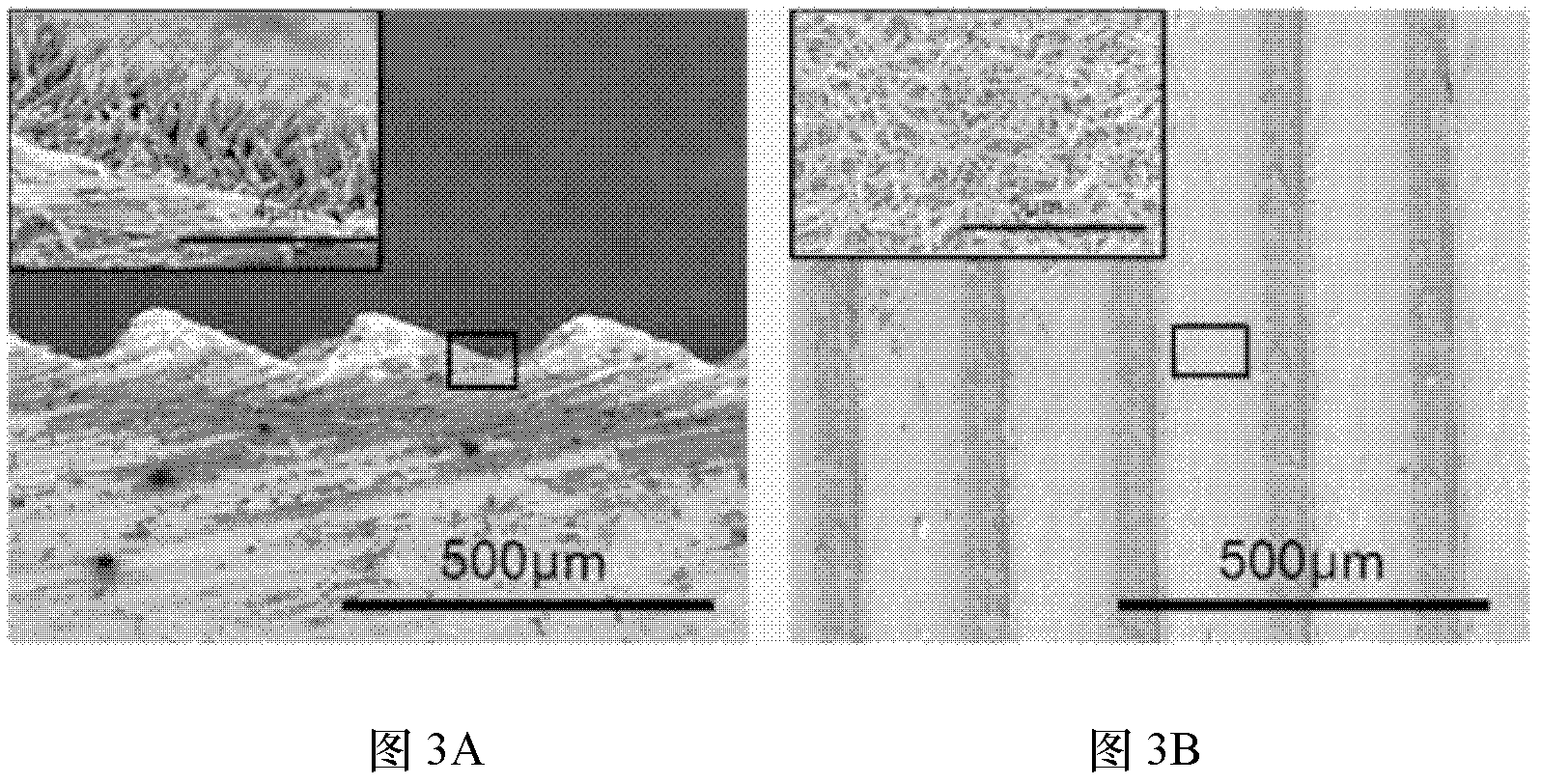

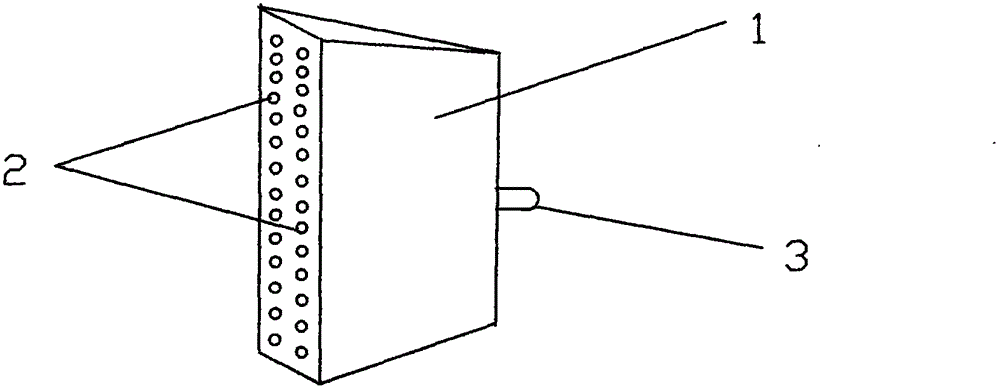

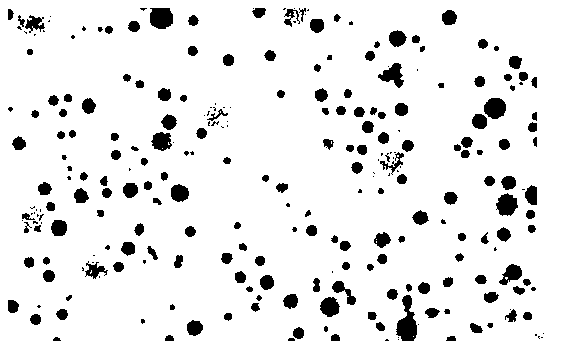

Core material of dot matrix laminboard and manufacturing method of core material by using extruding and interlocking

InactiveCN103302908AEasy snap-in assemblySimple processLaminationLamination apparatusDot matrixMaterials science

The invention discloses a core material of a dot matrix laminboard and a core material manufacturing method by using extruding and interlocking, and relates to a core material of the laminboard and a manufacturing method for the core material. The invention aims to solve the problems that the preparation technology of the conventional core material of the dot matrix laminboard is complicated, the cost is high, and the core material is difficultly produced in batches. According to a scheme I, each connection strip is integrated by a plurality of X-shaped units which are sequentially connected with one another; notches are formed above the intersections of the X-shaped units; two groups of connection strips are perpendicular to each other and are clamped with each other through the notches. According to a scheme II, each connection strip comprises a plurality of V-shaped units and a plurality of connectors; the connection strips in two groups are clamped with each other through first notches and notches in the connectors. According to a scheme III, connection plates are extruded; the connection plates in the step 1 are cut into connection strips with the equal thicknesses; the two groups of connection strips are perpendicular to one another and are clamped with one another through the notches. According to a scheme IV, the difference from the scheme III is that the connection strips in the two groups are clamped with one another through the first notches and the notches in the connectors. The core material is used for preparing the dot matrix laminboard.

Owner:HARBIN INST OF TECH

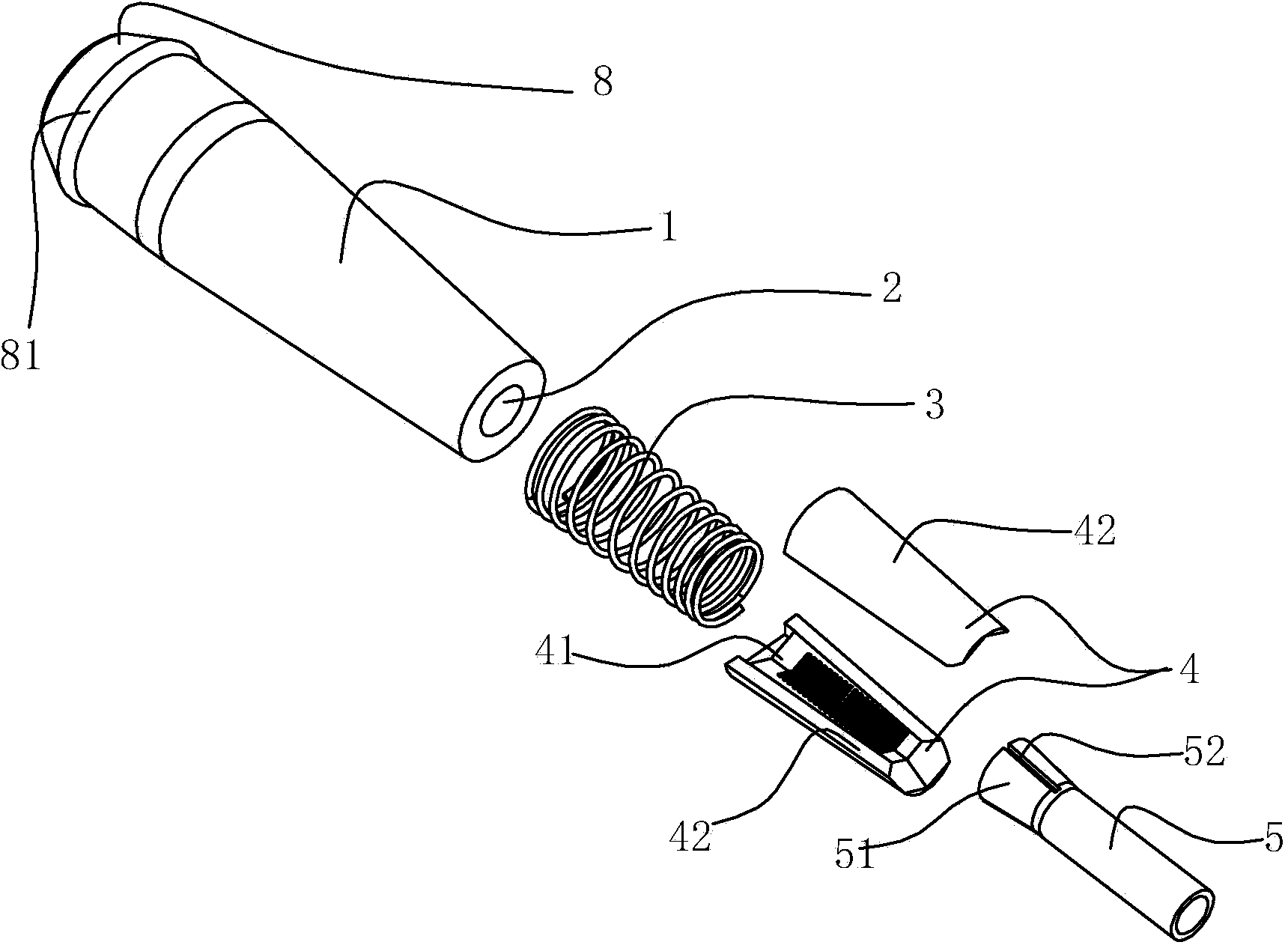

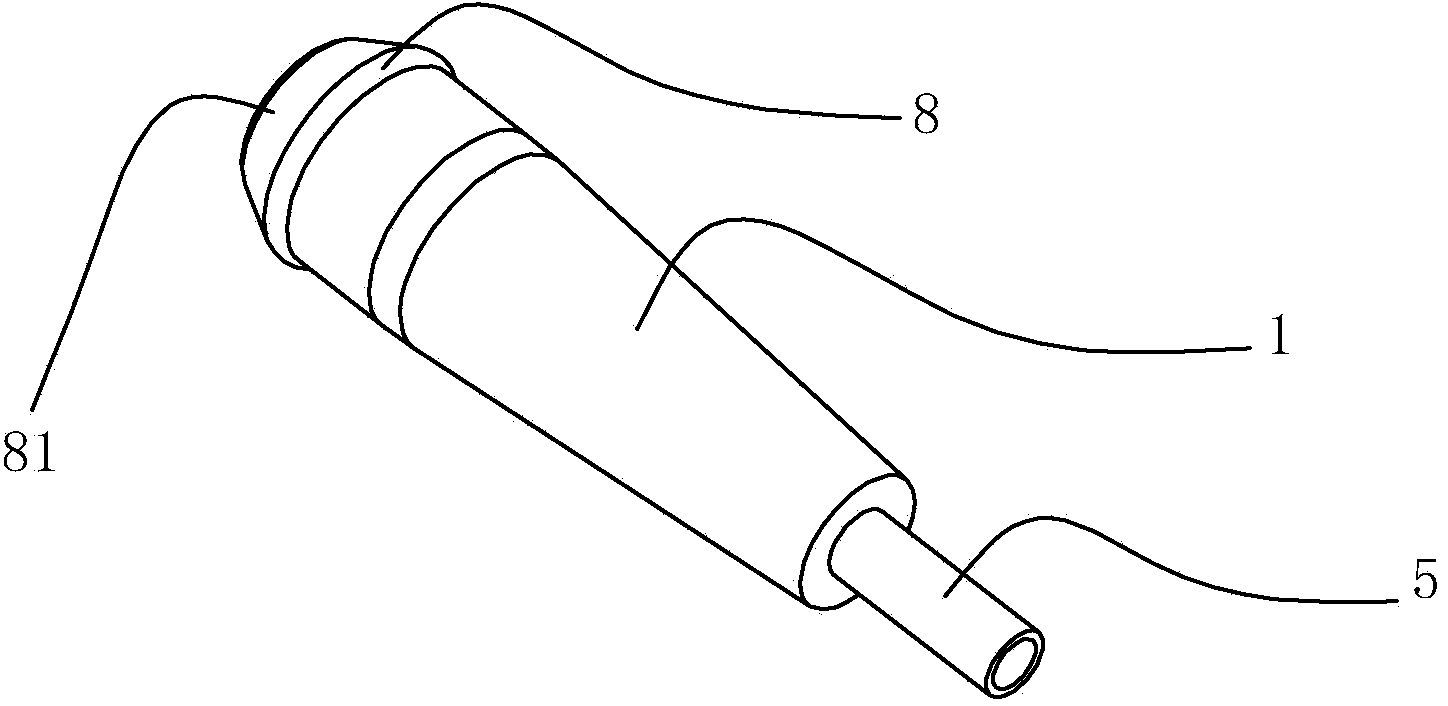

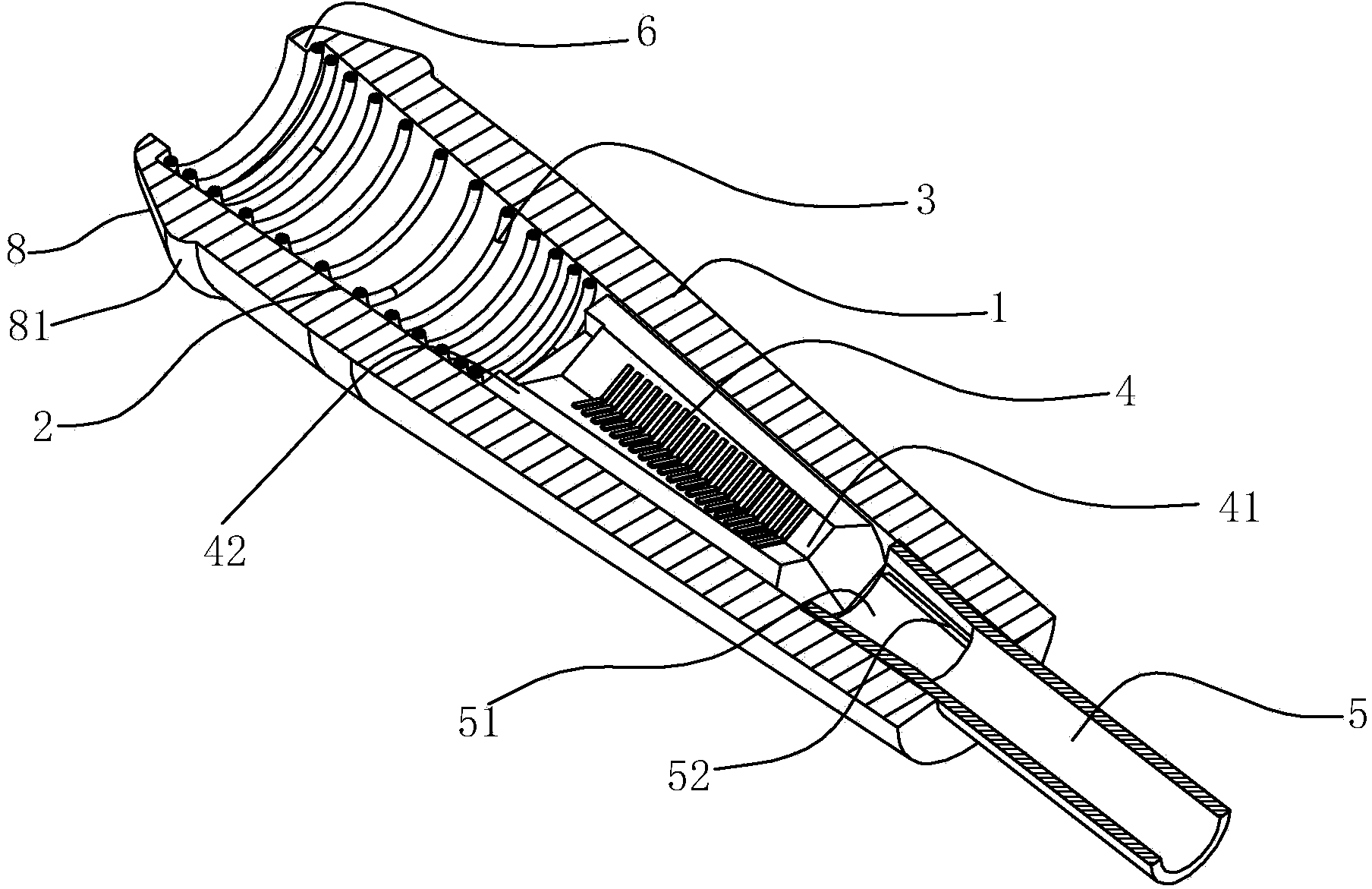

Quick connector for cables

ActiveCN103758926AFacilitated releasePull out easilyRopes and cables for vehicles/pulleyTextile cablesEngineeringElectrical and Electronics engineering

The invention relates to a quick connector for cables. The quick connector for the cables comprises a sleeve with a conical through hole, wherein a first spring and a cable clamp are arranged in the conical through hole in sequence from the large-diameter end to the small-diameter end, the first end of the first spring abuts against the wall of the large-diameter end of the conical through hole, the second end of the first spring abuts against the first end of the cable clamp, the cable clamp comprises at least two clamping jaws, grooves extending in the axial direction of the conical through hole are formed in the inner sides of the clamping jaws, an ejector sleeve is further arranged in the sleeve, the first end of the ejector sleeve is located at the small-diameter end of the conical through hole and abuts against the second end of the cable clamp, and the second end of the ejector sleeve stretches out of the conical through hole. The quick connector for the cables has the connecting function of a traditional quick connector and has the advantages that the cables can be released conveniently, both time and labor are saved, energy is saved, environmental friendliness is achieved, connecting reliability and connecting stability can be guaranteed due to the adoption of the structure, and the quick connector is convenient to use and practical.

Owner:宁波迅联机械制造有限公司

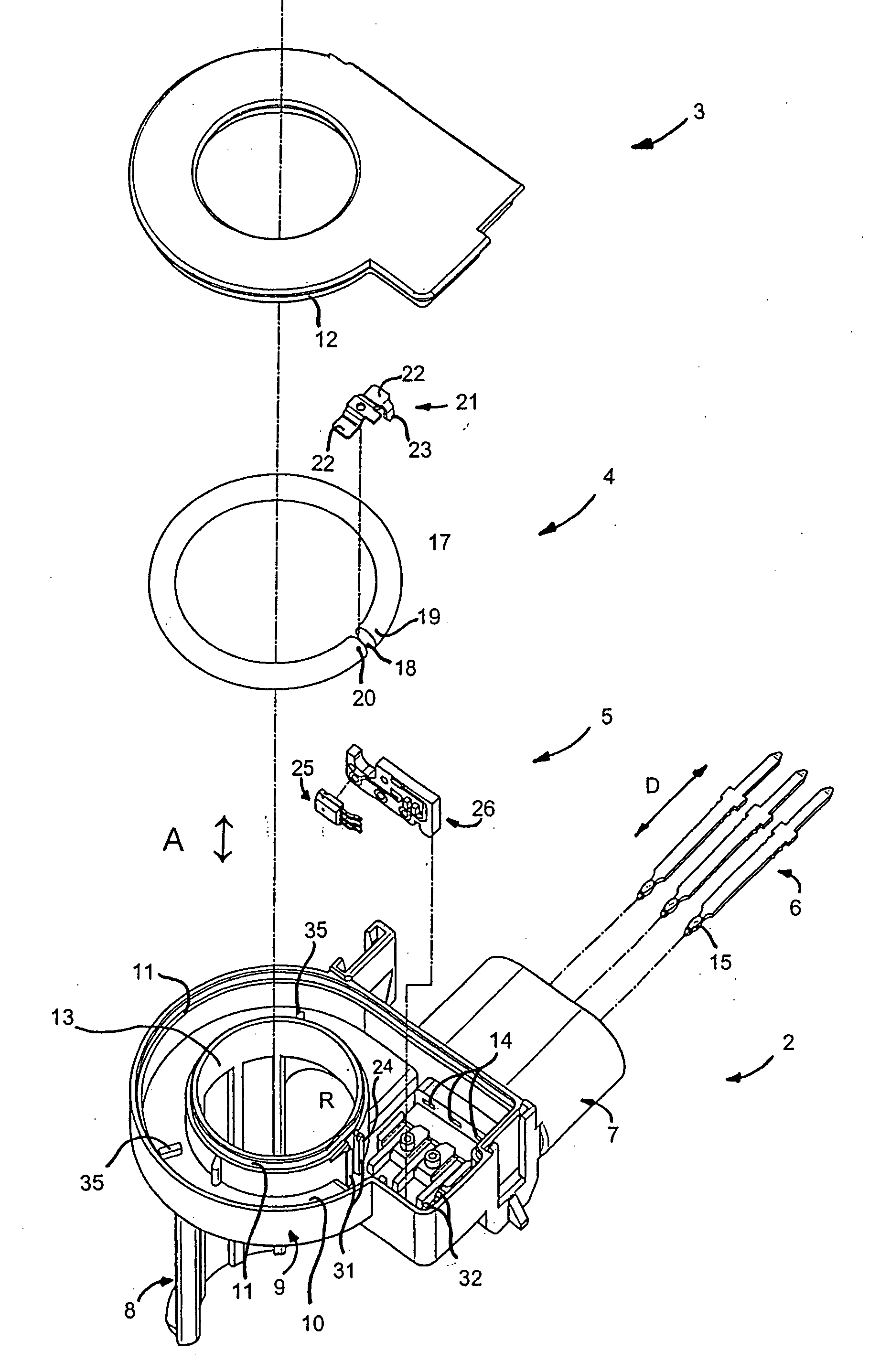

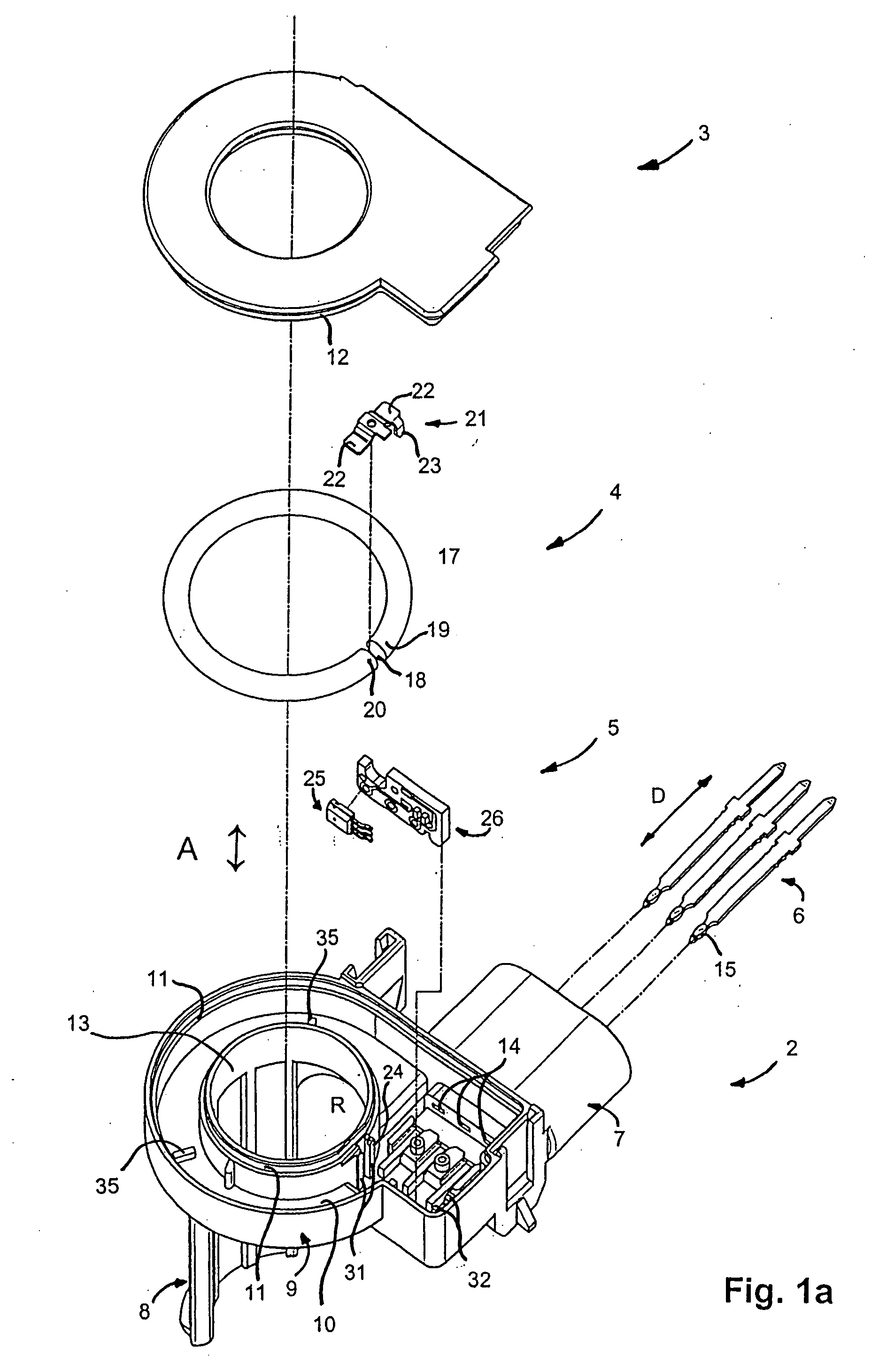

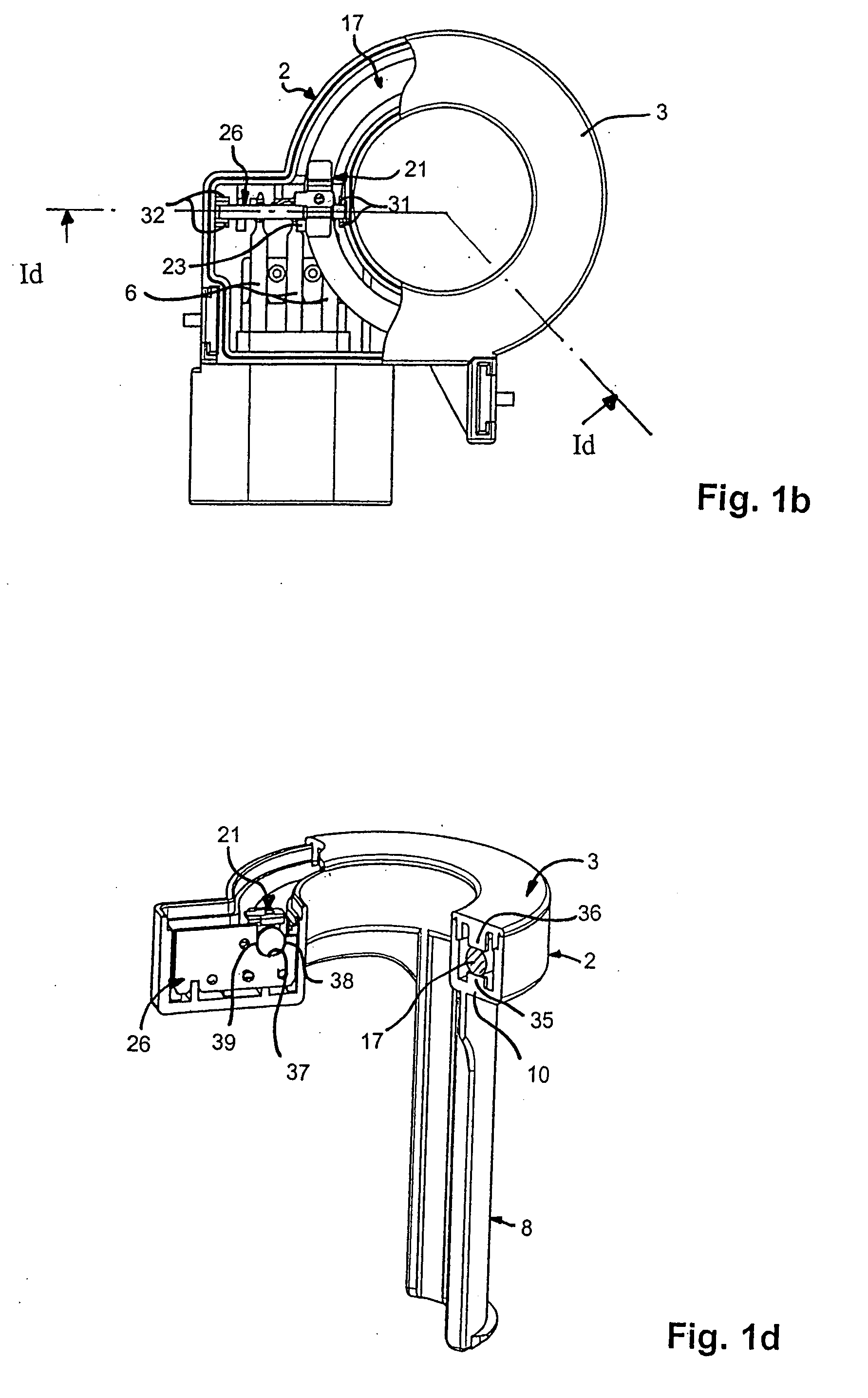

Electric current sensor

ActiveUS20080290857A1Easy to operateImprove automationMeasurement using dc-ac conversionVoltage/current isolationEngineeringNon magnetic

An electric current sensor having a housing, magnetic circuit with a magnetic core, and a magnetic field detector with a detection cell, positioned in an air gap between ends of the core. The core is made of a non-laminated magnetic material, and the magnetic circuit has a strap made of non-magnetic material welded to the core at each side of the air gap. The magnetic field detector has a support plate on which the detection cell is mounted. The plate has a recess, opposition the detection cell, which houses one end of the magnetic circuit.

Owner:LEM INT SA

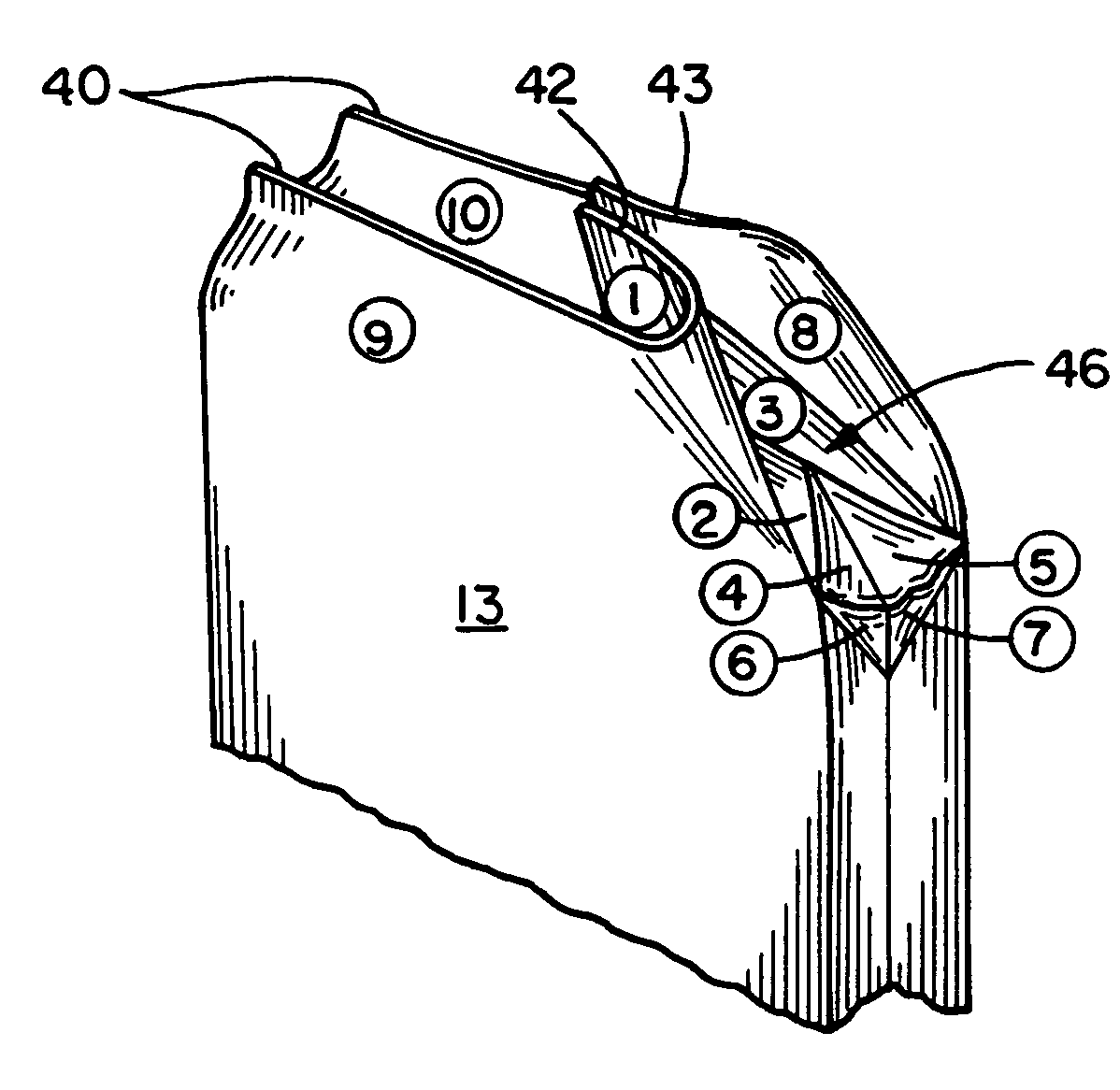

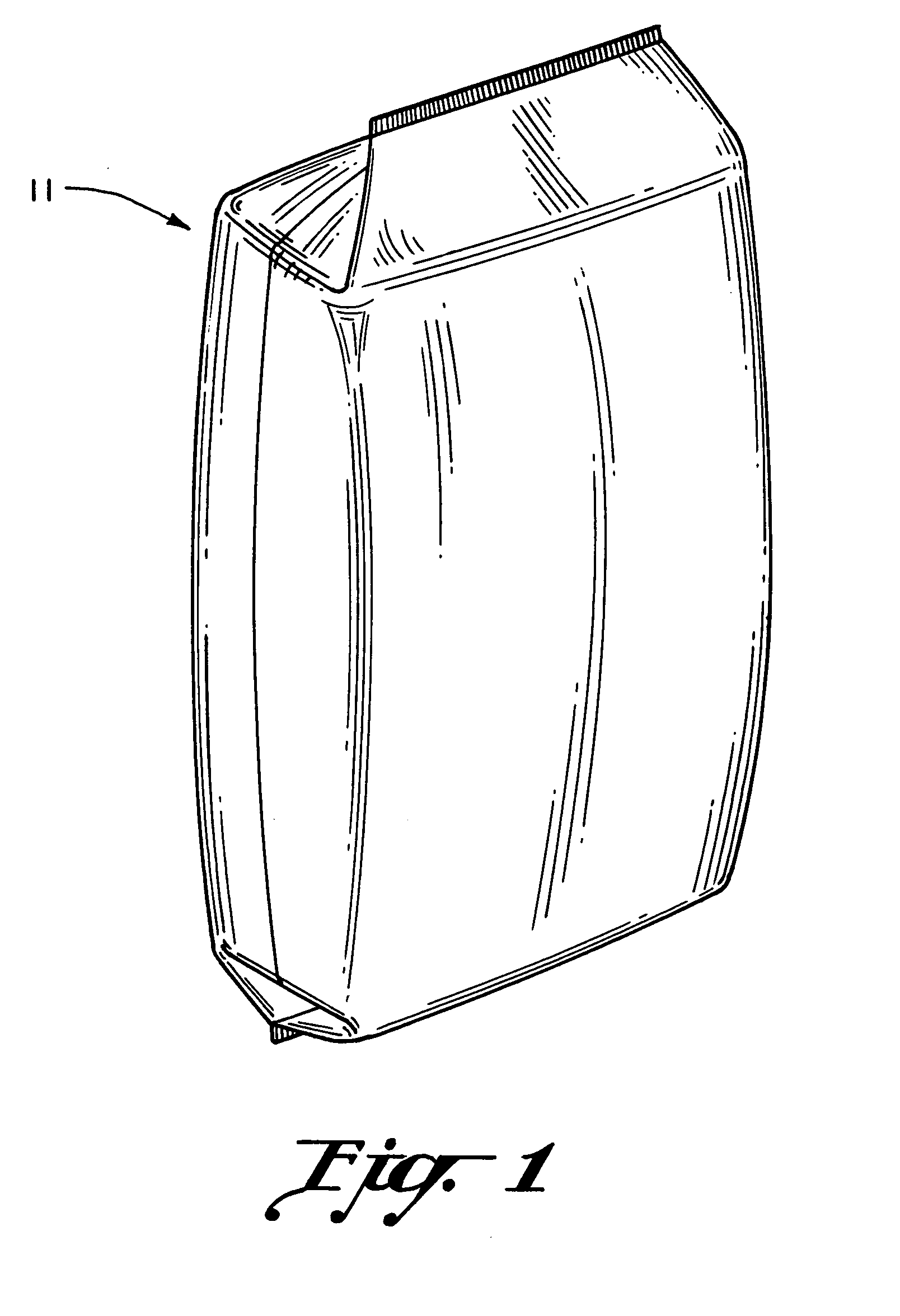

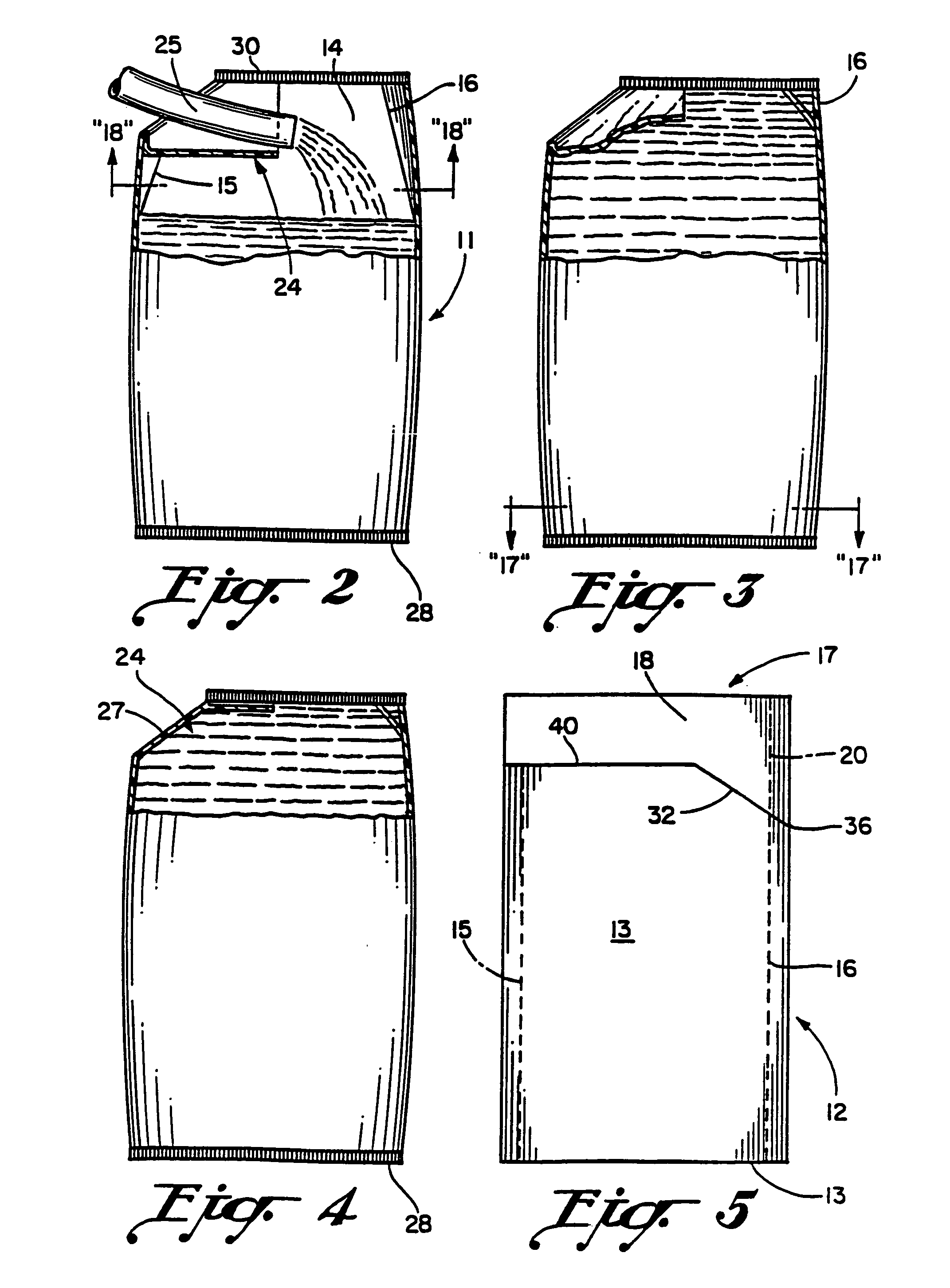

Side gusseted poly bag with a filling valve and its method of manufacture

ActiveUS6997858B1Labor savingSave materialEnvelopes/bags making machineryBag making operationsGusset plateEngineering

Owner:MORAVEK LAWRENCE R

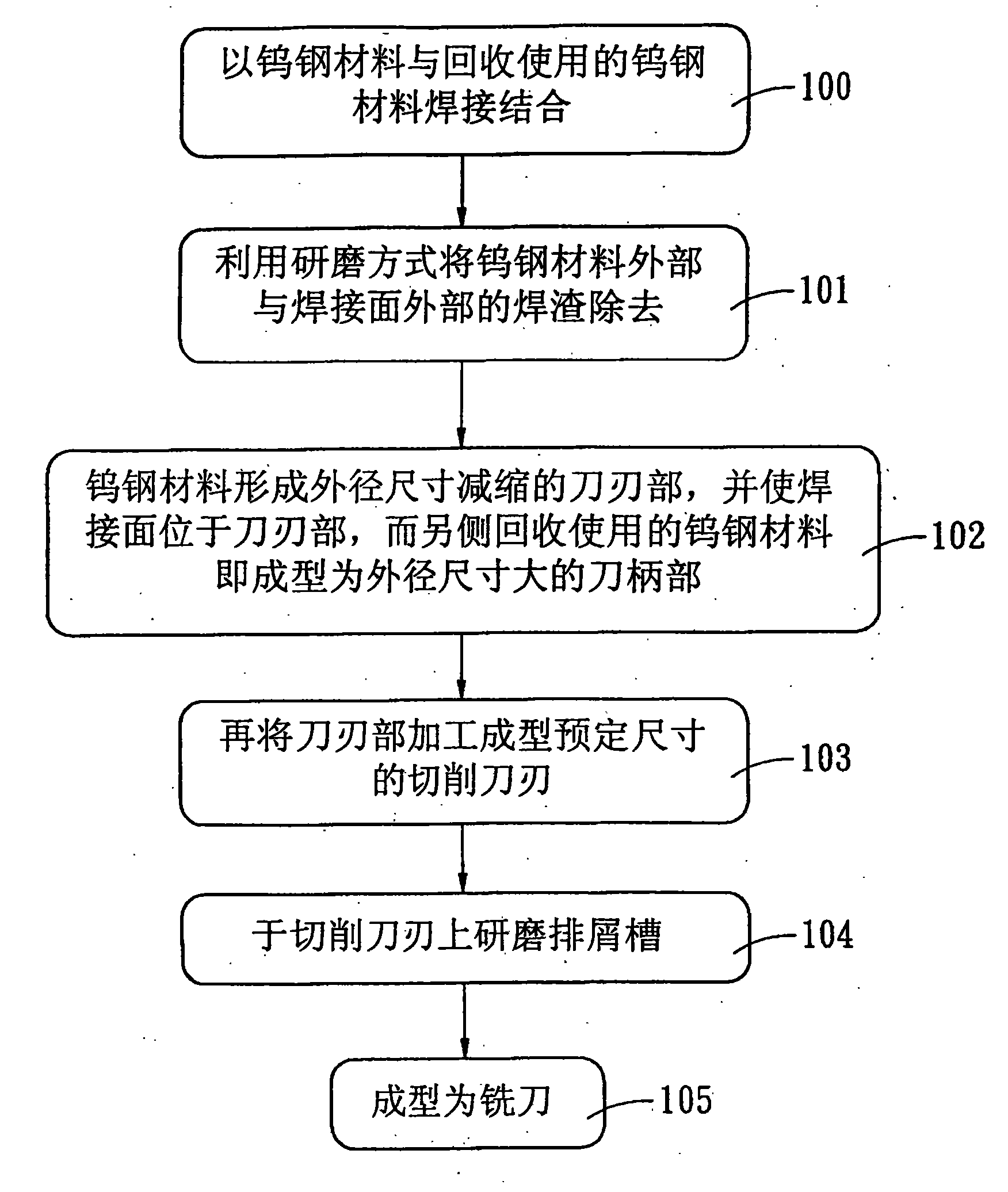

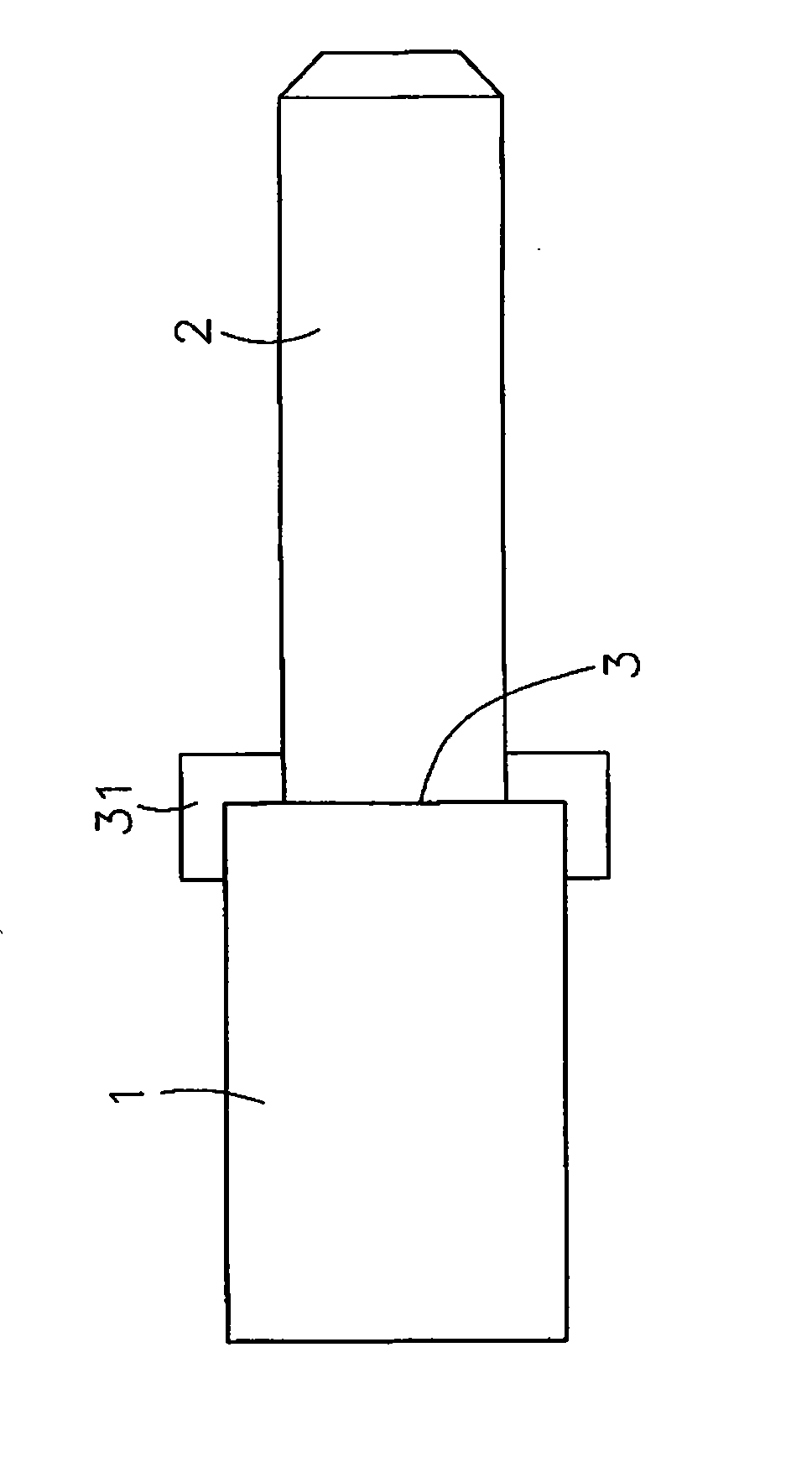

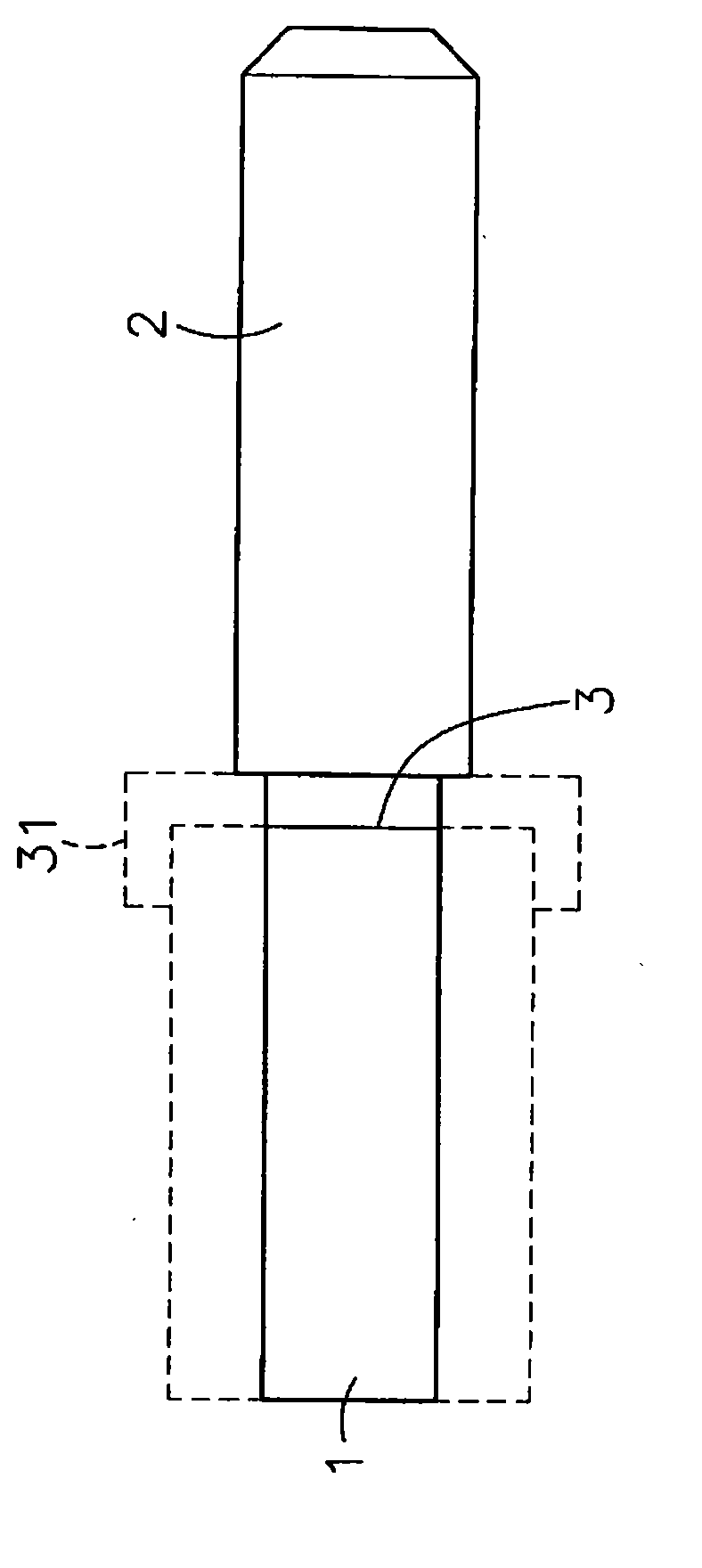

Method for manufacturing milling cutter

The invention relates to a method for manufacturing a milling cutter, in particular to the method for manufacturing the milling cutter by grinding machining to make the jointed milling cutter have good concentric roundness. The method comprises the following steps: performing welding joint on a brand-new tungsten material and a recycled tungsten material, wherein the outer diameter of the brand-new tungsten material is greater than that of the recycled tungsten material, and the new tungsten material is easy to weld in a contraposition way and has good concentric roundness; grinding to removewelding slag outside the brand-new tungsten material and a welding surface in a grinding mode to make the brand-new tungsten material form a blade part with a reduced outer diameter size and make thewelding surface positioned in the blade part; molding the recycled tungsten material on the other side into a handle part of which an outer diameter size is greater than that of the blade part; machining and molding the blade part into a cutting blade of a predetermined size; and forming a slag discharge groove on the cutting blade by grinding to mold the milling cutter. Therefore, the molded blade part and the handle part have good concentric roundness, and the milling cutter achieves the aims of quick molding, high product qualification rate and no material waste.

Owner:TOPOINT TECH

Bamboo fungus culture medium and preparation method thereof

InactiveCN104193446AFast and healthy growthLow costBio-organic fraction processingOrganic fertiliser preparationPorosityAdditive ingredient

The invention relates to the field of edible mushrooms and particularly relates to an artificially-bred bamboo fungus culture medium. The bamboo fungus culture medium comprises the following components in parts by weight: 20-25 parts of bamboo bits, preferably bamboo rhizome bits with the age of over two years, 10-20 parts of brown wood bits, 10-15 parts of bamboo leaves, 10-15 parts of bamboo forest humus soils, 2-5 parts of potatoes, 5-10 parts of bagasse, 10-15 parts of wheat straws, 2-5 parts of soybean meal, 0.3-0.5 part of glucose, 0.5-1 part of calcium superphosphate, 0.5-1 part of magnesium sulfate, 0.5-1 part of ammonium nitrate and 0.5-1 part of hydrated lime, wherein the bamboo leaves and the wheat straws are soaked and bubbled for over 30 days by use of water in a fermenting tank, properly dried in the air after being bubbled until the moisture content is 25%-35%, wherein the integral moisture content of the culture medium is 70%-80%; and the culture medium is pressed by beating and compacted, so that the porosity is smaller than 10%. The culture medium is complete in nutritional ingredient, moderate in acid and alkaline condition, and capable of meeting the growth needs of the bamboo fungus and greatly increasing the yield of the artificially-bred bamboo fungus.

Owner:商丘学院

Connector

ActiveCN102195214AReduce crosstalkImprove shielding effectCoupling contact membersTwo-part coupling devicesGround contactElectric potential

The present invention provides a card edge connector as a high-speed differential signal connector configured to equalize electric potentials of ground contacts adjacent to signal line contacts, and thus to reduce crosstalk between adjacent signal line contacts. The card edge connector serves as a female connector in which multiple signal line contacts and multiple ground contacts are arranged inparallel in at least one row. In the card edge connector, the signal line contacts and the ground contacts are arranged in a way that every two signal line contacts for high-speed signals to send andreturn respectively therethrough are interposed between two ground contacts, and all of the multiple ground contacts arranged in the one row are electrically connected to one another by use of a common contact.

Owner:YAMAICHI ELECTRONICS

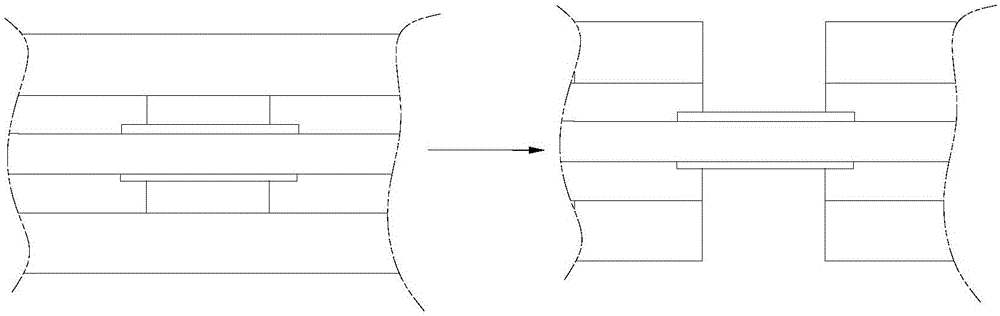

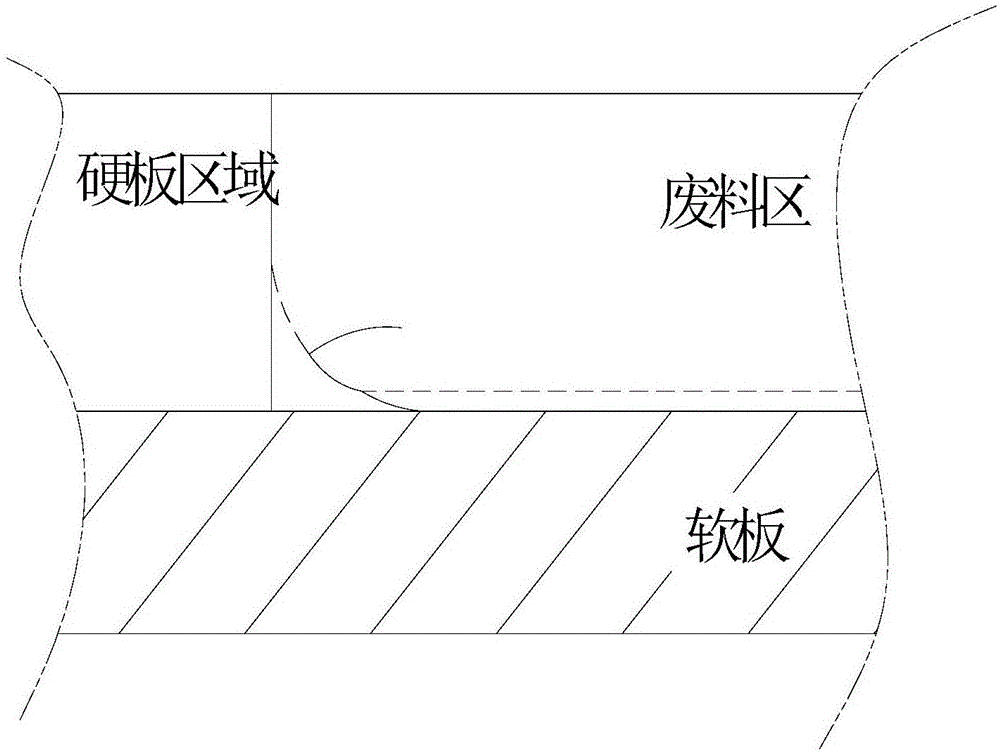

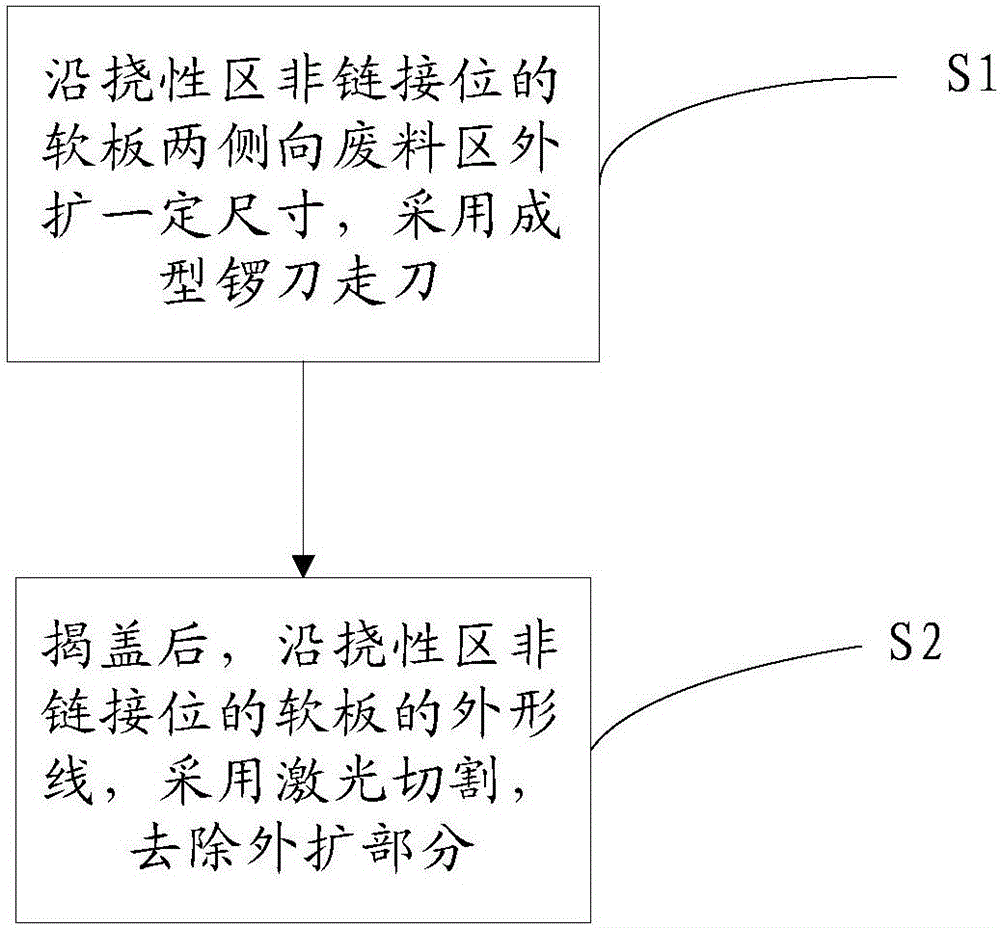

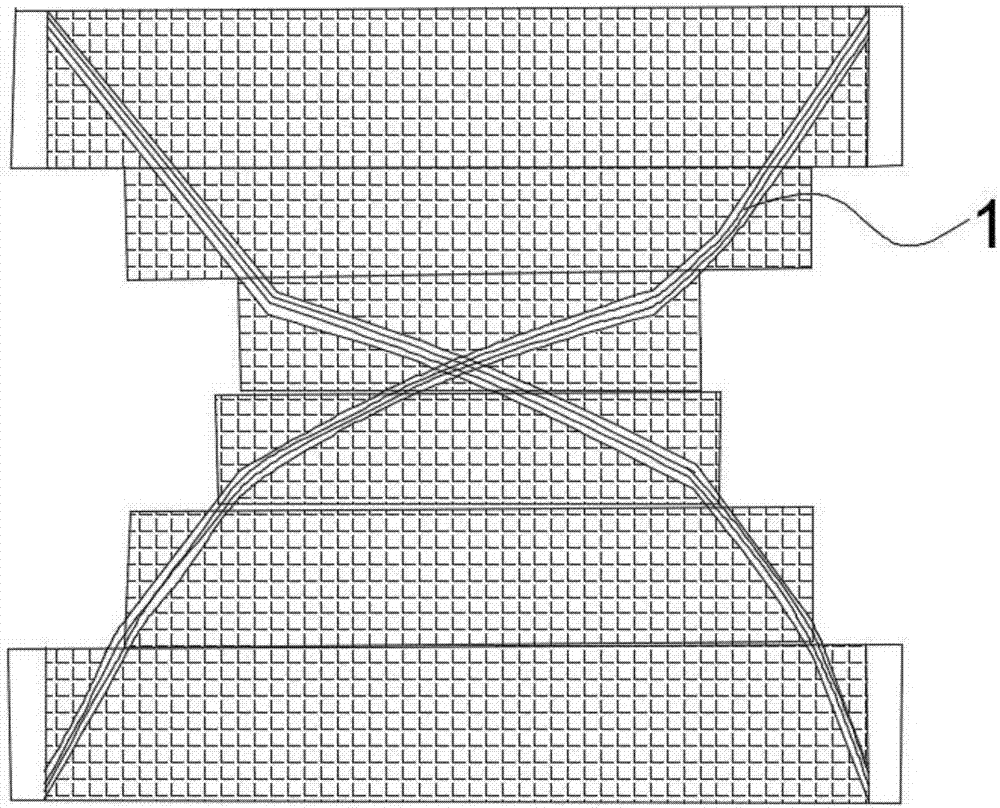

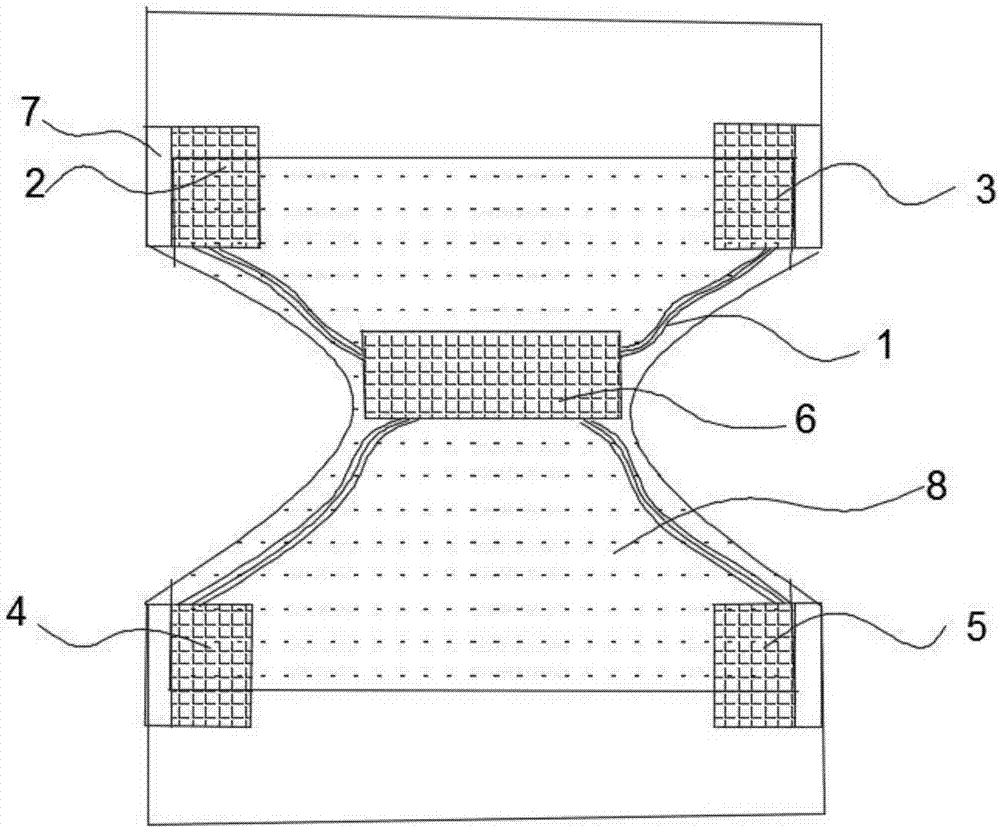

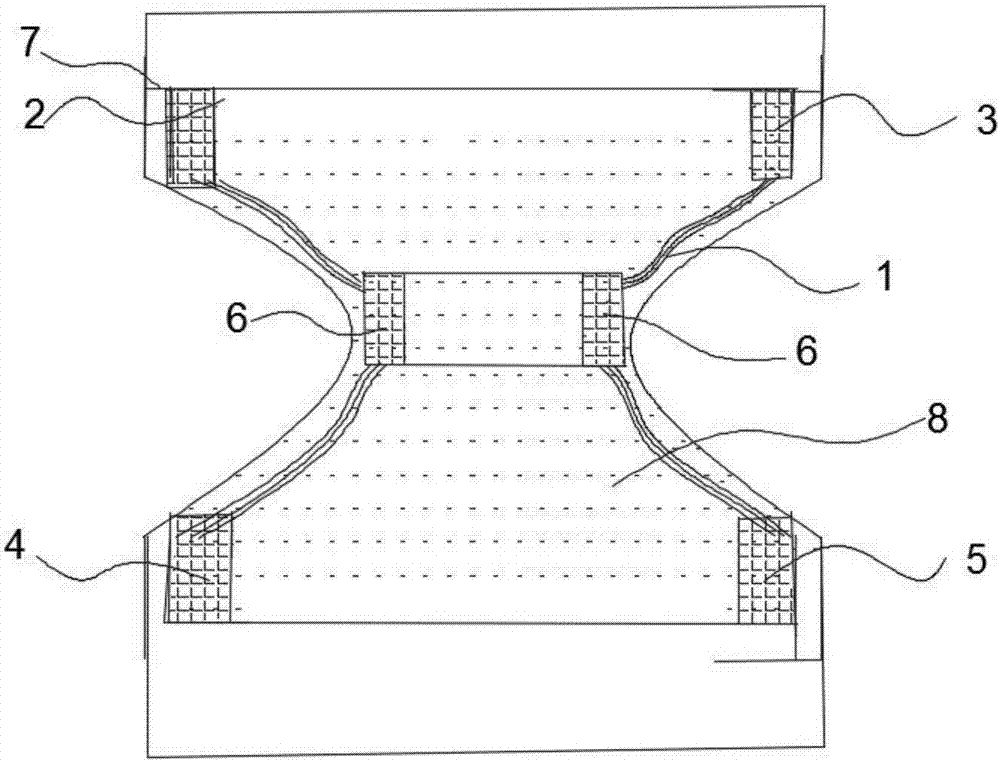

Processing method for removing burrs from flexible printed circuit board region of rigid-flexible printed circuit board

ActiveCN106658970AHigh precisionSolve glitchesFlexible printed circuitsPrinted circuit manufactureMilling cutterEngineering

The invention relates to a processing method for removing burrs from a flexible printed circuit board region of a rigid-flexible printed circuit board. The processing method comprises the following steps of expanding along the two sides of a flexible printed circuit board in a non-linking position in a flexible region to a waste material region for a certain dimension, and feeding by adopting a shaping milling cutter; and after uncovering, adopting laser cutting along the outline of the flexible printed circuit board in the non-linking position in the flexible region to remove an outward-expansion part. According to the processing method, the step of expanding along the two sides of the flexible printed circuit board in the non-linking position of the flexible region to the waste material region for a certain dimension is performed by the shaping milling cutter in advance; then uncovering is carried out, and by adopting laser cutting, the outward-expansion part is removed along the outline of the flexible printed circuit board in the non-linking position in the flexible region, so that manual repairing is not required; the high precision of the outline precision of the flexible printed circuit board is maintained; the problem of burrs on the two sides of the flexible printed circuit board in the flexible region is solved; and effects of low cost and no waste of material are achieved.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

Construction method of water supply pipeline

ActiveCN111059353AEnsure safe water supplyAvoid Notes, ConservationDetection of fluid at leakage pointPipe laying and repairWater resource managementWater supply

The invention relates to a construction method of a water supply pipeline. The construction method comprises the following steps of 1, setting out and line inspecting; 2, trench excavation; 3, pipeline mounting; 4, carrying out a pipeline experiment and a leakproofness experiment; 5, pipeline backfilling; and 6, inspection well periphery backfilling. The construction method has the beneficial effects that the experiment period of a water supply pipeline pressure test can be effectively shortened, and the cost of the test can be effectively reduced.

Owner:QINGDAO HUADE METER MFGD & ENG CO LTD

Rubber string adhesive applying and fixing method of pull-ups with warps

InactiveCN106859856AExcellent adhesionPaste firmlyLiquid surface applicatorsAbsorbent padsAdhesiveEngineering

The invention discloses a rubber string adhesive applying and fixing method of pull-ups with warps. The method includes the steps that non-woven cloth of a base layer of a body of the pull-ups is unfolded and spread, an X-shaped rubber string area is determined, and six adhesive coating regions are arranged on peripheral areas of four corners of the X-shaped rubber string area, a waist intersected area and other areas except an upper edge area and a lower edge area respectively; the side faces of the adhesive coating regions at the four corners are provided with connection parts respectively; the first five adhesive coating regions are subjected to adhesive shaving, the sixth adhesive coating region is subjected to adhesive spraying, and a rubber string is fixed and attached; then the non-woven cloth covers the rubber string, and the rubber string is fixed among multiple layers of non-woven cloth; the corresponding connection parts are subjected to thermo-compression bonding. The method is simple, rubber strings are effectively saved, waste is prevented, and the touch feeling of the product is improved.

Owner:HANGZHOU HAOYUE INDAL

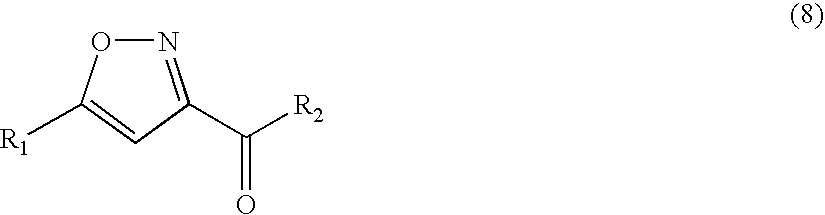

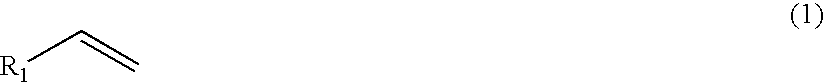

Method for manufacturing isoxazole derivative or dihydroisoxazole derivative

There is provided with a method for manufacturing an isoxazole derivative at a high yield and without discharging waste products, and a novel isoxazole derivative. An isoxazole derivative expressed by Formula (8) is produced by reacting a 1-alkyne compound expressed by Formula (7) with iron(III) nitrate in the presence of acetone or acetophenone: (where R1 is an alkyl, cycloalkyl, phenyl, or other such group); and (where R2 is a methyl or a phenyl).

Owner:GAKUIN RIKKYO

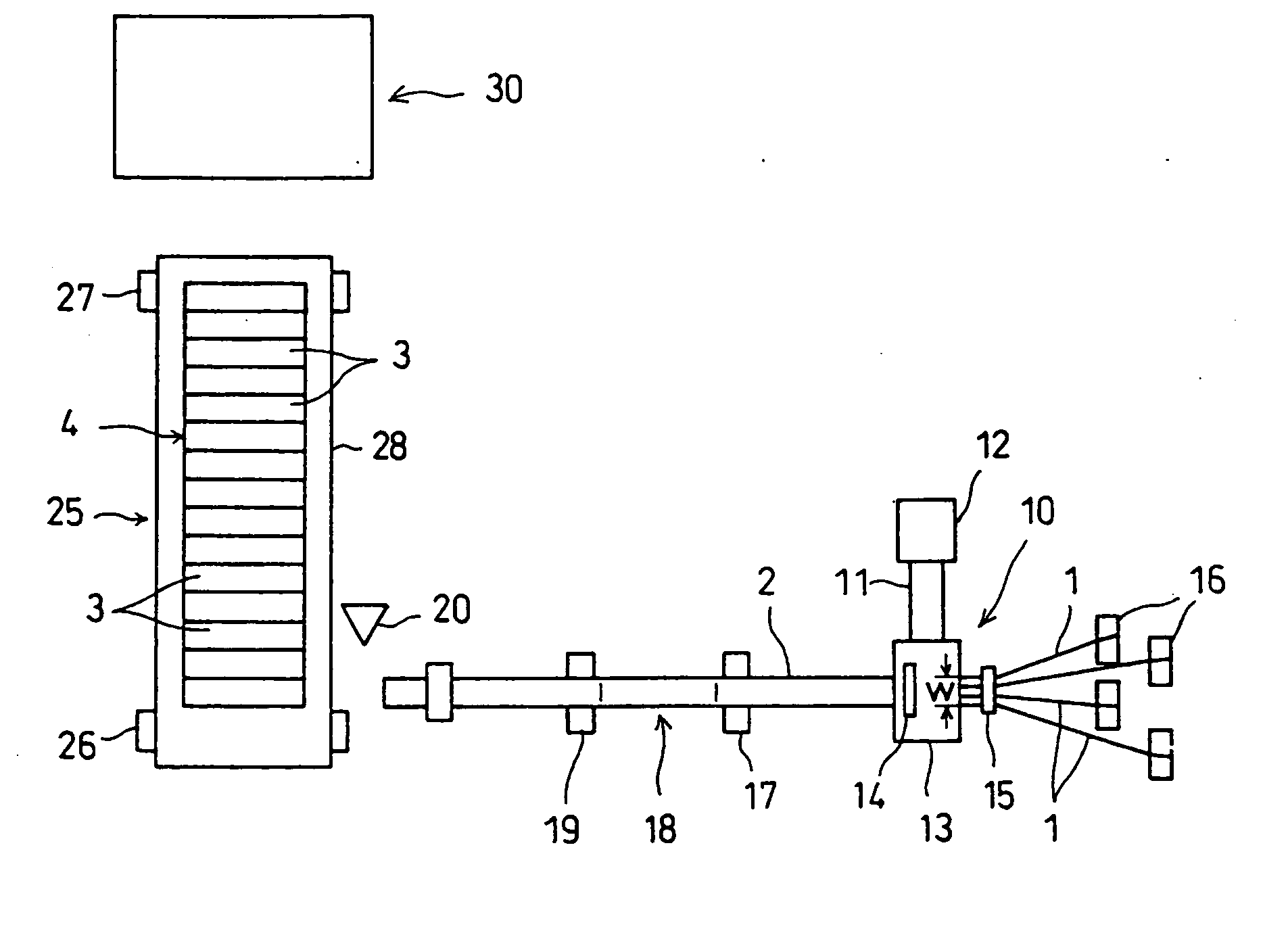

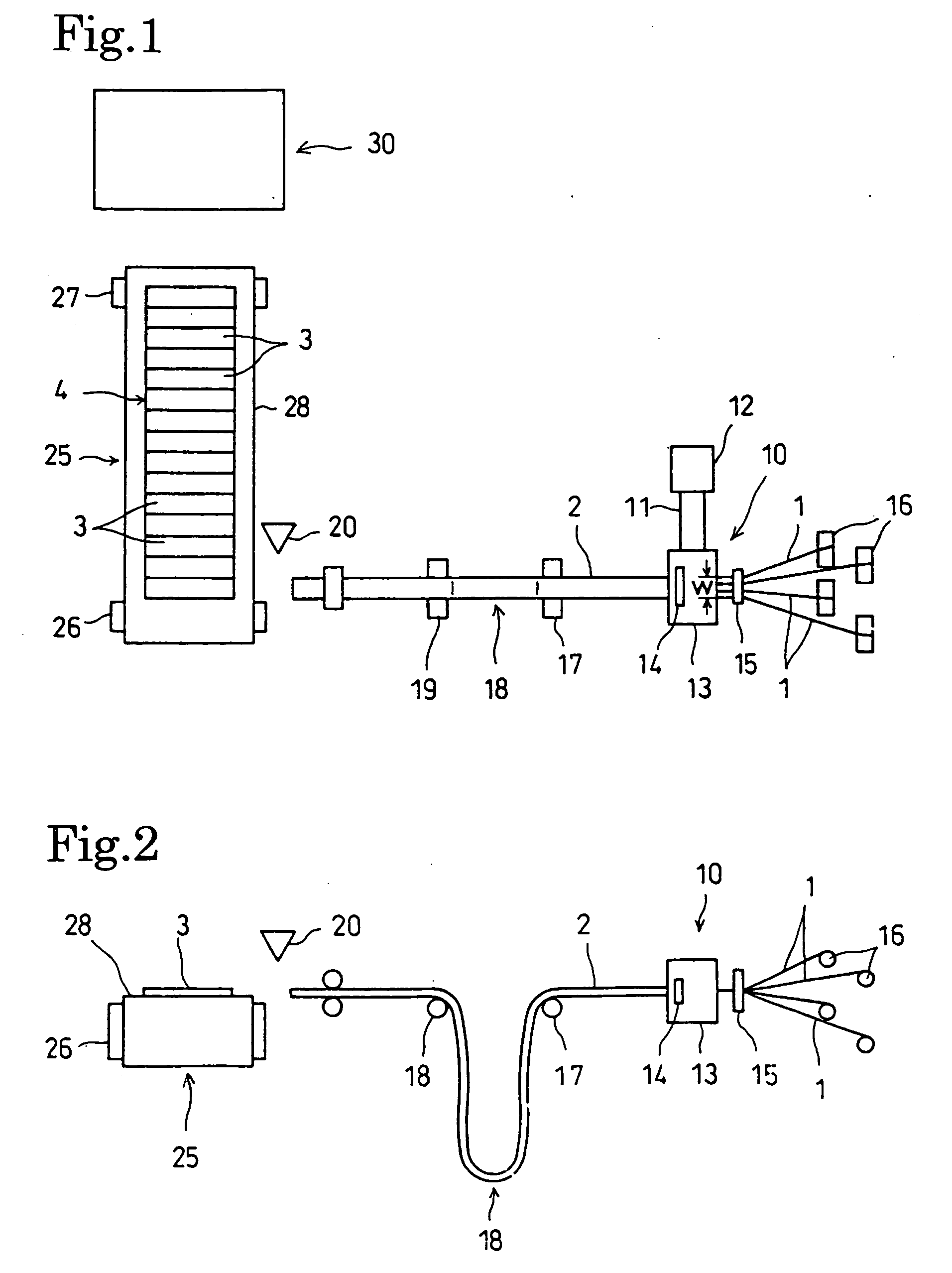

Method of manufacturing tire component member and pneumatic tire

InactiveUS20050178488A1Forming accuratelyNotLamination ancillary operationsLaminationEngineeringIncreasing weight

A tire component is fabricated by the steps of forming a narrow belt by arranging a plurality of cords and embedding the cords in a rubber layer, cutting the belt into strips of a predetermined length, and successively arranging and joining a necessary number of the strips such that edge parts of adjacent strips overlap each other with the outermost cord in the edge part of one of the adjacent strips overlying the outermost cord in the edge part of the other strip. The strips can be surely joined without requiring advanced techniques, without wasting materials and without increasing weight. Thus a desired annular tire component can be accurately formed in a desired circumference. The cords are arranged in each strip in a width equal to a length shorter than a length equal to an integral division of the predetermined circumference of a tire by a length corresponding to an increase in the diameter of the tire component. A tire component of a predetermined circumference can be accurately formed by increasing the diameter of an annular ply fabricated by successively joining an integral number of the strips such that the edge parts of the adjacent strips overlap each other with the outermost cord in the edge part of one of the adjacent strips superposed on the outermost cord in the edge part of the other strip. A pneumatic tire including the thus formed carcass ply thus fabricated has an improved quality.

Owner:BRIDGESTONE CORP

Culture medium for low-cost pleurotus eryngii

InactiveCN103408362AFast and healthy growthLow costFertilizer mixturesBiotechnologyAdditive ingredient

A culture medium for low-cost pleurotus eryngii comprises the following ingredients by weight percent: 70-75% of wheat straw, 10-15% of cotton seed, 5-10% of soybean powder, 0.3-0.5% of glucose, 0.5-1% of quick lime, 1-2% of hydrated lime, 0.1-0.2% calcium superphosphate and 0.1-0.2% of magnesium sulphate; the wheat straw is soaked in water in a fermentation pool for more than 20 days, and is then dried properly to have a water content of 25-35%; the total water content of the culture medium is 70-75%; the wheat straw, the cotton seed and the soybean powder are mixed according to respective ratio, and the rest of nutrition ingredients are scattered on the upper surface of or in the upper layer of the culture medium; the culture medium is tightly compressed, and the void ratio is lower than 10%. The culture medium adopts low-cost and reachable materials, the nutrition ingredients can satisfy the requirement for the growing of the pleurotus eryngii, and can facilitate the domestic manufacturing of pleurotus eryngii by a peasant.

Owner:江苏惠发农业科技发展有限公司

A Method of Seedling Breeding of Fritillaria

InactiveCN106489470AFull of nutritionMeeting nutritional needsBiocideBio-organic fraction processingFertilizerChlamydomonas

The invention relates to a method for seedling raising of Fritillaria, which comprises the following steps: (1) the humus-containing loam soil or sand is selected as the nursery land of Chlamydomonas subspecies; (2) the land of the control tiger are strewed by Pesticide 1- 2kg; (3) 15- 20 days later, the land is made to the ridge, the base fertilizer are spread on the ridge, and then soil, cover the base fertilizer, level the land, and finally cover with 1cm- 1.5cm mountain (5) to keep the soil moist, until spring emergence, cover density of 50 after emergence- 60 sun-shade net.(4) the pretreatment of seeds are sprinkled on the ridge, the seeds are covered with shrimp, pine and cooked soil; 60 shade net; (6) Miao long 3cm after every 20-25 days fertilizer once, fertilizer in accordance with the 300kg per mu, according to the amount of 5kg per acre, 45-60 days spraying foliar fertilizer once. The seedling rate of the seedling is less than 4%, and the rate of insects is less than 1.5%, and the germination rate is 90.2%.The incidence rate is less than 3.5%, the seedling rate is 93.4% , bulb weight to 1.5g, much higher than the existing nursery method.

Owner:YULONG JINWANG CHINESE MEDICINAL HERBS PLANTING CO LTD

Continuous mixing supply method for acid fracturing fluid

The invention discloses a continuous mixing supply method for acid fracturing fluid. The method includes the following steps of mixing: feeding a thickener premixed solution, acid fluid and various fluid additives into an integral mixing system for solution mixing so as to obtain the uniformly-mixed acid fracturing fluid, and solution distribution: supplying and discharging the acid fracturing fluid obtained in the mixing step. By the mixing method, continuous mixing supply of water, the acid fluid, dry powder or pasty fluid and the various fluid additives can be realized, mixing effect is good, mixing is uniform, and quality of the fracturing fluid is high; in addition, by realization of a continuous automatic acid preparing process, a large amount of labor cost is reduced, the requirement on a fluid storage tank is lowered, construction fluid is saved, and equipment cost is saved.

Owner:李磊

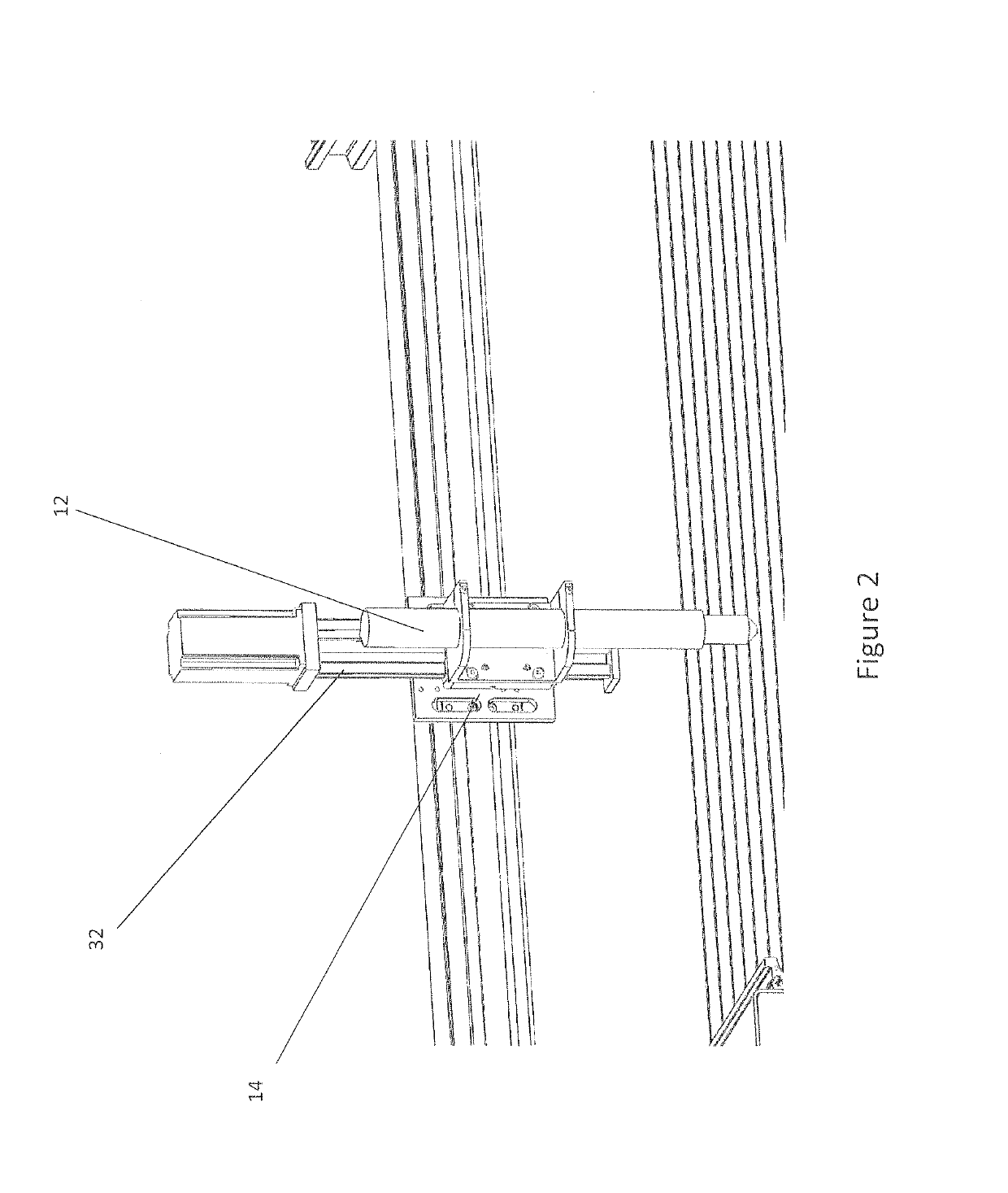

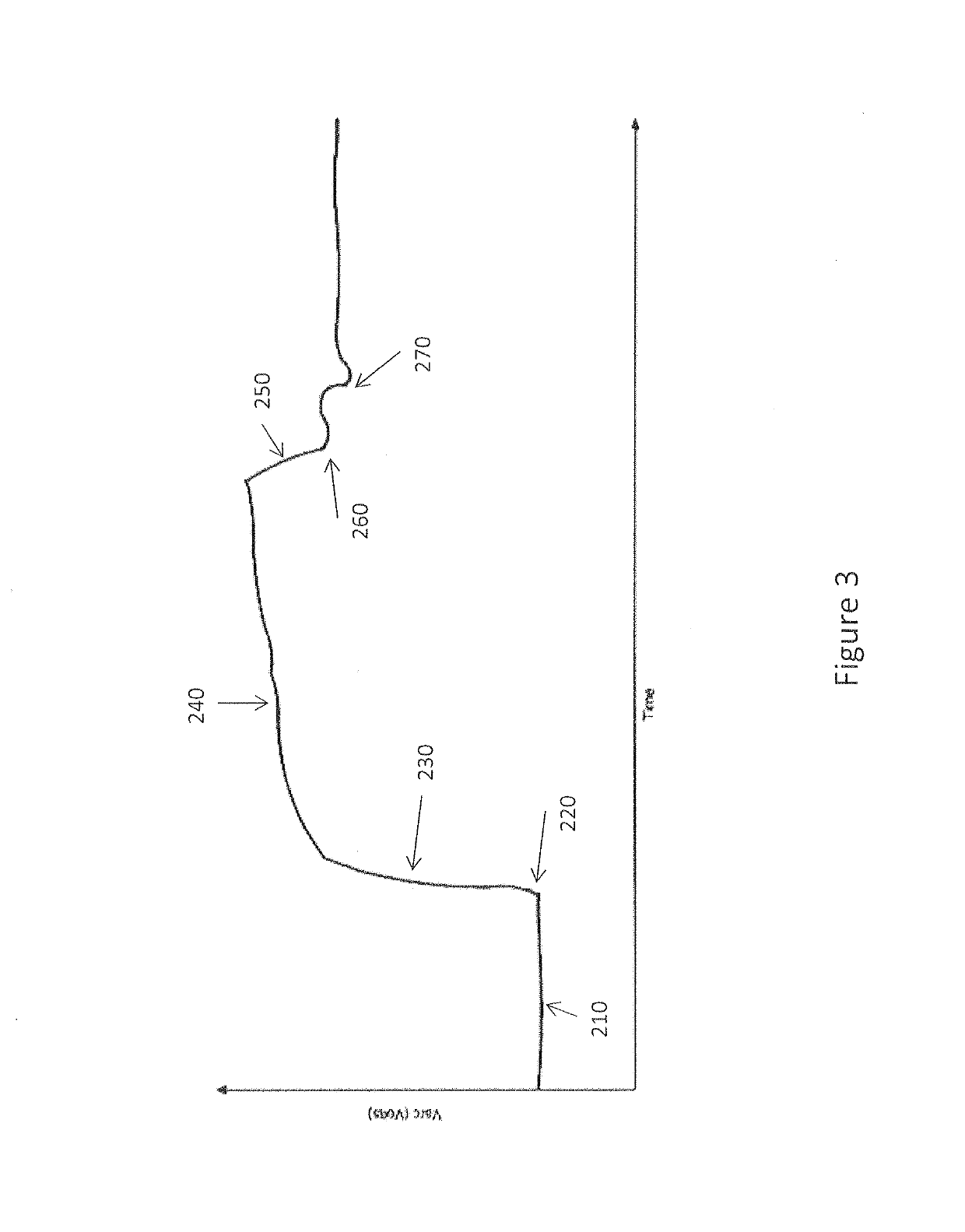

System and methods for improved sheet metal cutting with improved sharper corners cutting technique

A plasma cutting system for measuring or monitoring the voltage between a plasma torch and the material being cut to determine a voltage or voltage signature and comparing that measurement against predetermined values to indicate that an initial pierce of the material is complete, and based on the measurement, moving the torch or the material to a different location for additional cutting. The system further provides a Fix Drawing Tool, which will automatically detect and fix gaps or overlaps in a drawing that are very difficult to find visually. These gaps and overlaps become a problem when trying to make a proper toolpath because a CAM program requires a clean, closed shape. The system also provides a Dynamic Corner Looping system, which automatically adjusts with the feed-rate and accelerations of the toolpath and plasma machine, eliminates unwanted dross, sharpens corners and minimizes material loss. A pendant tethering system is also disclosed for managing control of a CNC machine remotely. Additional disclosed functionality includes a data collection system, a manual hand wheel with 3D simulation and a multiple fabrication head management system.

Owner:WORTH PFAFF INNOVATIONS

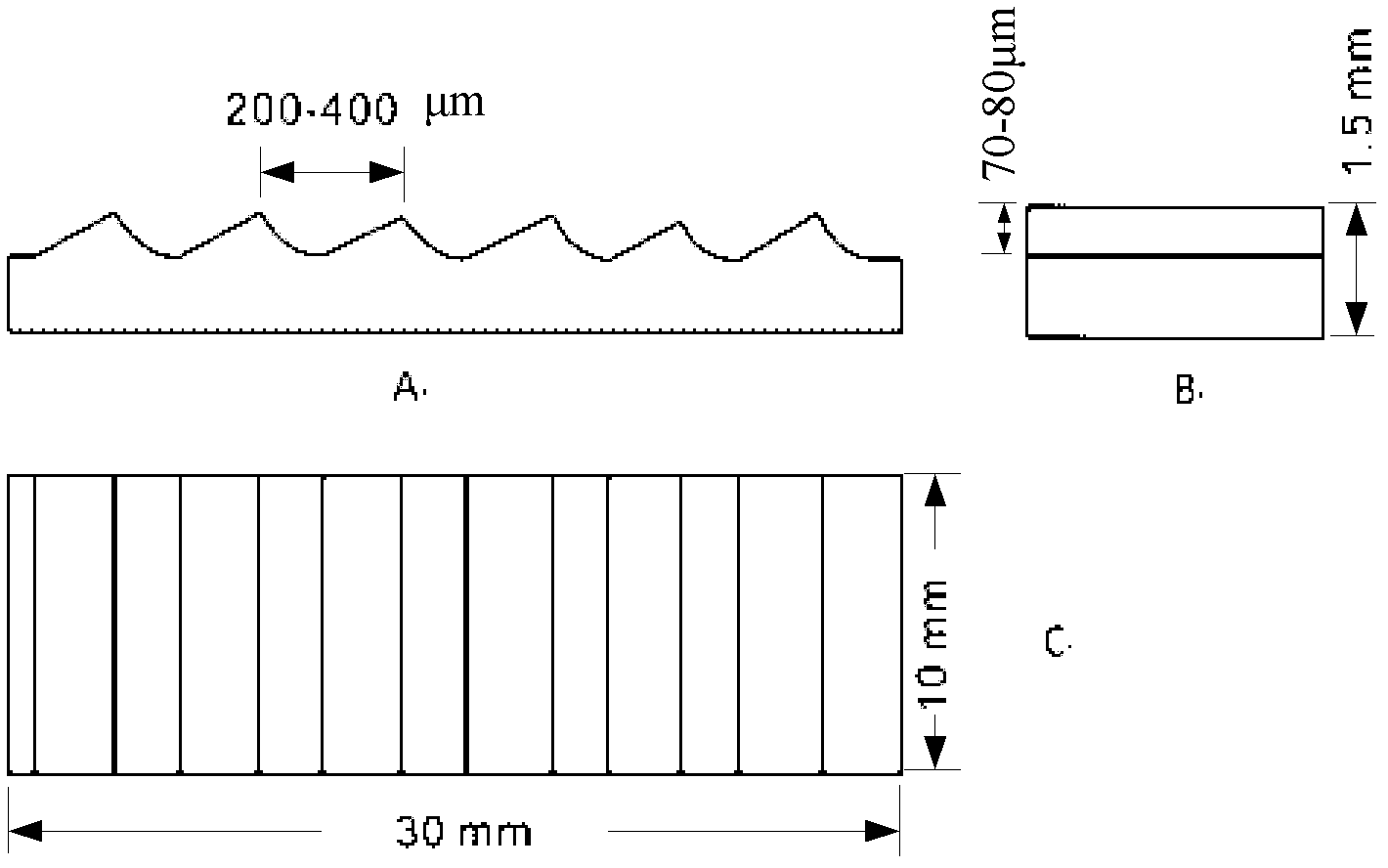

Preparation method of ice coating prevention surface of bionic micro-nano composite structure

ActiveCN102492945BImprove surface roughnessReduce contact areaVacuum evaporation coatingSputtering coatingMicro nanoMicro structure

The invention discloses an ice coating prevention surface of a bionic micro-nano composite structure and a preparation method thereof, and belongs to the technical fields of chemistry and materials. The preparation method comprises the steps of: processing a surface micro structure on the surface of a substrate, planting a nano structure on the surface micro structure and finishing the surface toobtain the ice coating prevention surface. The ice coating prevention surface has a micro-nano composite structure, thus the surface roughness of the material is greatly increased, the contact area between liquid drops and the surface of the substrate is reduced, and the surface of the substrate not only has hydrophobicity, but also has lower adhesion property; under the condition of -10 DEG C even -15 DEG C, the surface has hydrophobic and anti-icing effects, and the icing time is larger than 7200 seconds; and the ice coating prevention surface can be formed on multiple materials, thus the limit to low-temperature icing prevention of the materials is greatly widened.

Owner:BEIHANG UNIV

Spray head

InactiveCN102716822AExpand the spraying areaSpray evenlySpray nozzlesMechanical engineeringRaw material

Owner:王光树

Dephosphorizing agent for low-silicon molten iron steelmaking and preparation and using method thereof

The invention belongs to the field of steel metallurgy technology and resource recycling, and relates to a dephosphorizing agent for low-silicon molten iron steelmaking and a preparation method and using method of the dephosphorizing agent. Magnesium reducing slag, lime particles and scale are mixed according to the mass ratio being (0.5-3):(1-2):(0.5-3), fully and uniformly mixed by a ball mill, added with a binder, and pressed by a ball press to obtain the dephosphorizing agent with the particle size being 1-60mm, and the dephosphorizing agent comprises, by mass, 25%-75% of CaO, 15%-65% of Fe2O3, 5%-25 % of SiO2, 1%-8% of MgO and 0.3%-3% of Al2O3. The proportion of the magnesium reducing slag is adjusted according to the silicon content of the molten iron in the preparation process, so that a multi-element dephosphorization slag system with low melting point and high fluidity can be formed. Recycling application of magnesium reduction slag can be achieved, the problems of difficult slagging, high slag melting point, likely gun sticking and the like of low-silicon molten iron steel making can be solved, the dephosphorization slagging speed is increased by 10% or more, and the dephosphorization rate is increased by 5% or more.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for preparing single embryo chromosome of flounder fish

The invention relates to a method for preparing a single embryo chromosome of flounder fish and belongs to the field of marine animal cytogenetics in biotechnology. The embryo of the flounder fish is used as a material, an injector is used as a tool, the egg membrane of the embryo material is broken by means of physical pressurization, the embryo between tail germ stage and hatching stage is placed in a syringe together with seawater, the piston of the injector is pushed so that the embryo is extruded out of the needle part, and then the membrane of the embryo can be broken and the tissue can be preserved relatively completely, and the chromosome preparation of the membrane-broken embryo is carried out according to a conventional chromosome preparation method; and the chromosome preparation specifically comprises the following steps of treating the membrane-broken embryo for two hours by using colchicine, then treating in a hypotonic solution for 30 minutes, and at last fixing the embryo by using a Carnot fixing solution, wherein each Carnot fixing takes 20 minutes. A lot of chromosome dividing phases of the flounder fish with very good effect are obtained by using the method provided by the invention, especially the chromosome of a single embryo can also be prepared without wasting material, and subsequent genetics analysis can be carried out on a single individual.

Owner:OCEAN UNIV OF CHINA

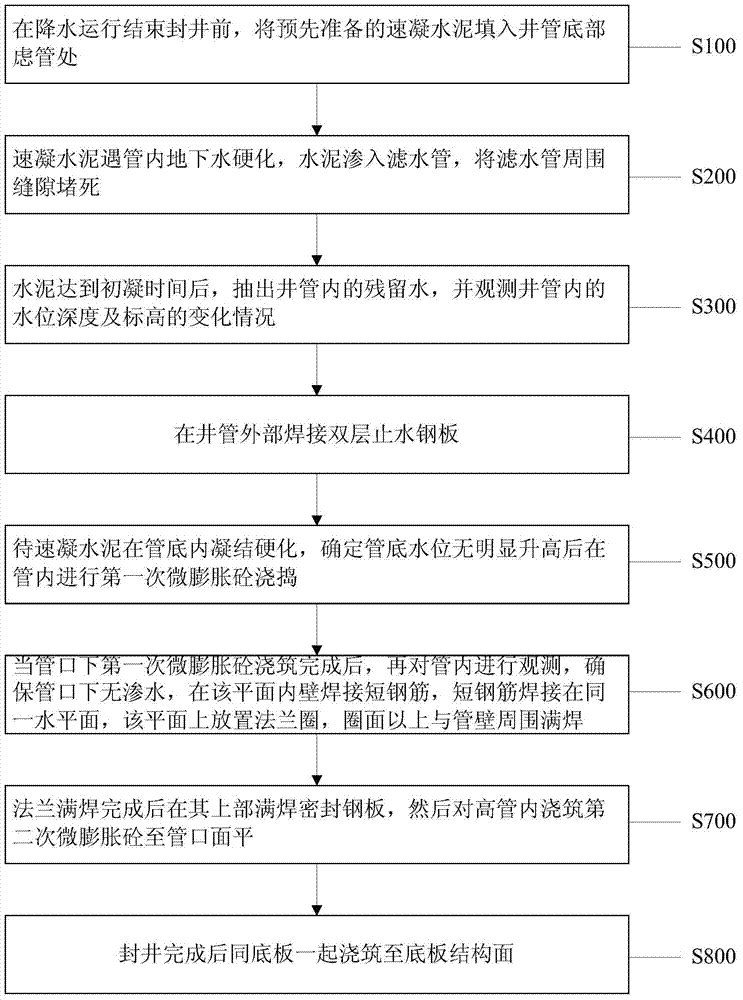

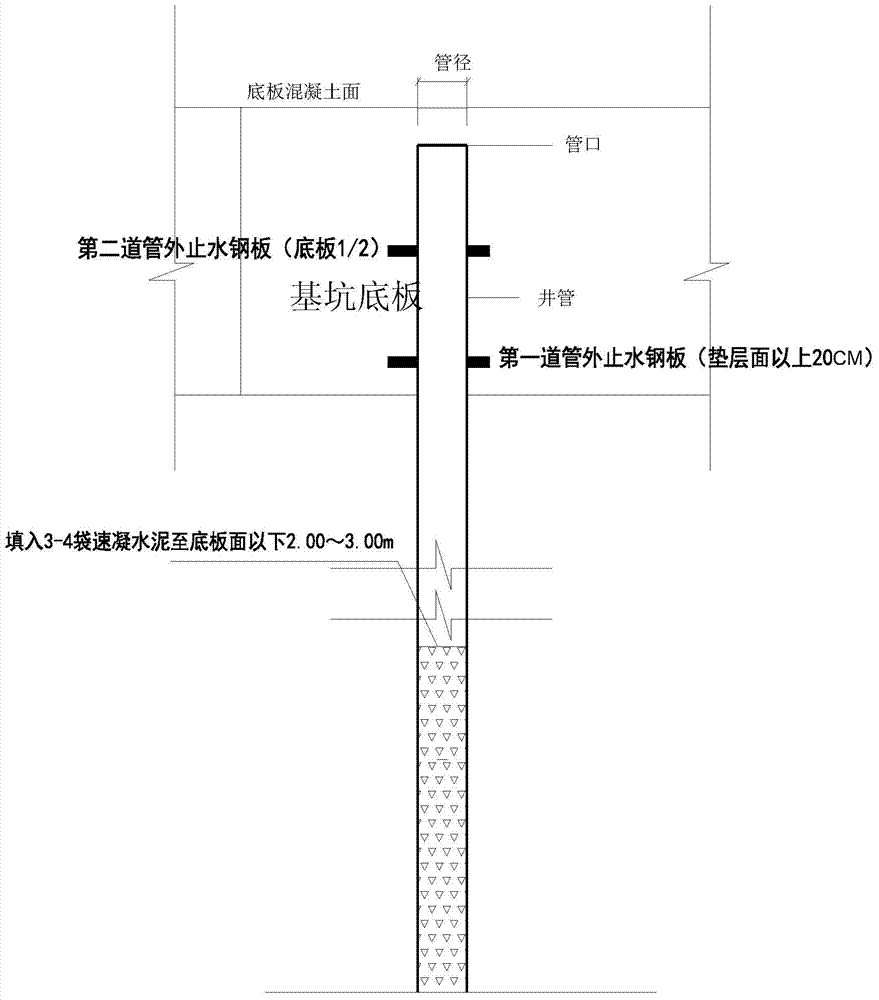

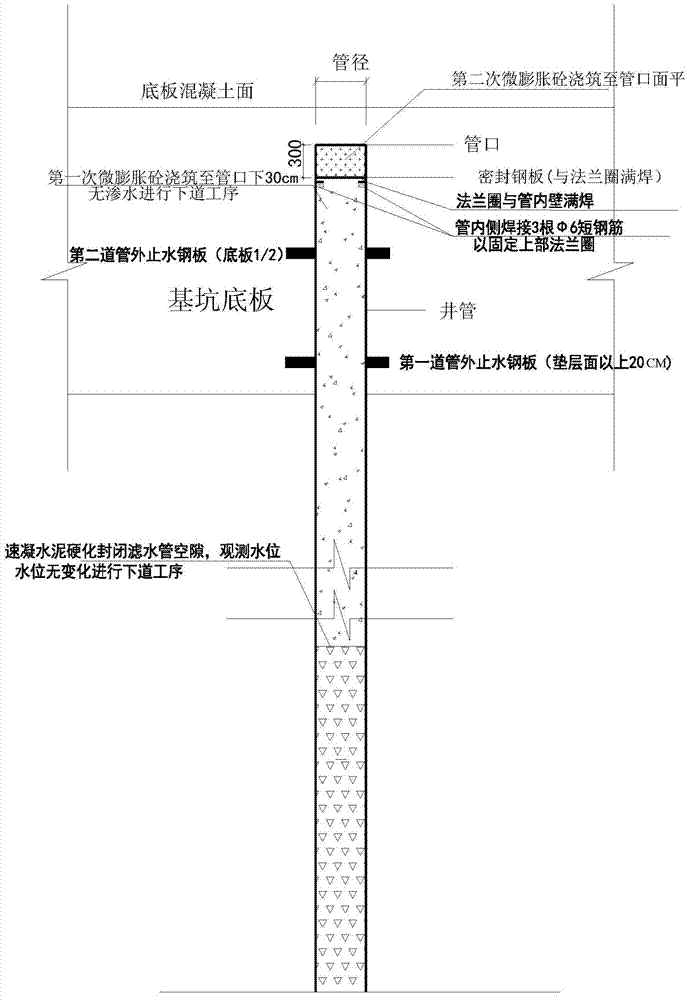

Construction method for blocking depressurization well by adopting accelerated cement

The invention discloses a construction method for blocking a depressurization well by adopting accelerated cement. The construction method includes the step 1, filling a filter pipe on the bottom of a well casing with the accelerated cement after precipitation and before well blocking, step 2, blocking gaps around the filter pipe after the cement hardens when meeting underground water in the casing and after the cement seeps into the filter pipe, step 3, pumping residual water in the well casing out after the cement reaches initial setting time, step 4, welding two layers of water stop steel plates outside the well casing, step 5, carrying out primary microdilatancy concrete pouring and smashing in the casing when the water level on the bottom of the casing does not rise obviously after the cement sets and hardens in the bottom of the casing, step 6, guaranteeing that water seepage does not exist below a casing mouth, welding short steel bars in the plane, placing a flange ring, and carrying out full weld on the portion, above the ring face and the portion, around a casing wall, step 7, welding and sealing the steel plates fully on the upper portion of the flange after full-weld is carried out on the flange, and then carrying out secondary microdilatancy concrete pouring in a high casing until the casing mouth face is flat, and step 8, pouring the high casing and a bottom plate to a bottom plate structural face after well blocking is completed. According to the construction method, operation is quick and convenient, well blocking periods are short, cost is low, and the construction method can be applied to later-stage different water yield situations of the depressurization well in a pit.

Owner:SHANGHAI NO 7 CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com