Positioning and reinforcing system and method for assembly type building cast-in-place connection layer reserved reinforcing steel bar

A technology for reserving steel bars and connecting layers, which is applied in the processing of building materials, construction, building construction, etc., can solve the problems that affect the correct positioning and installation speed of prefabricated walls, and affect the quality of installation, so as to reduce the cost of wall hoisting The effect of shortening the time of positioning, shortening the construction period, and not wasting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

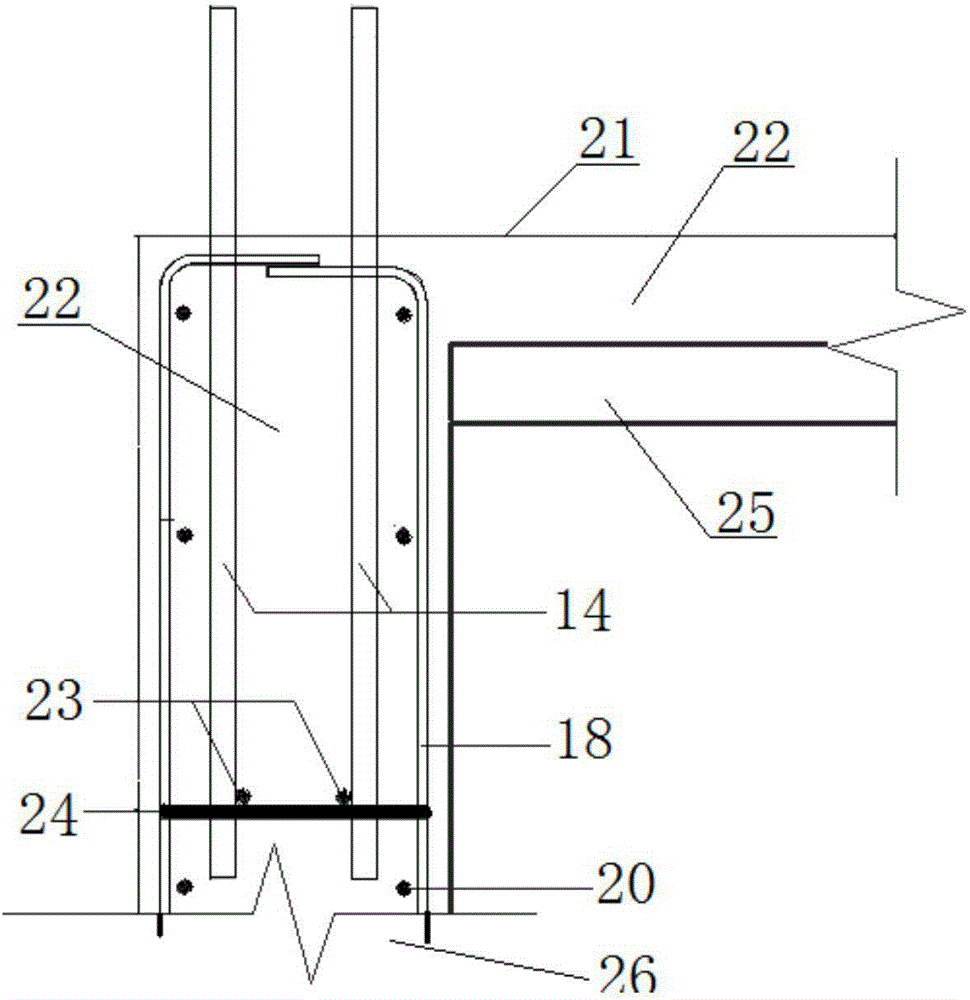

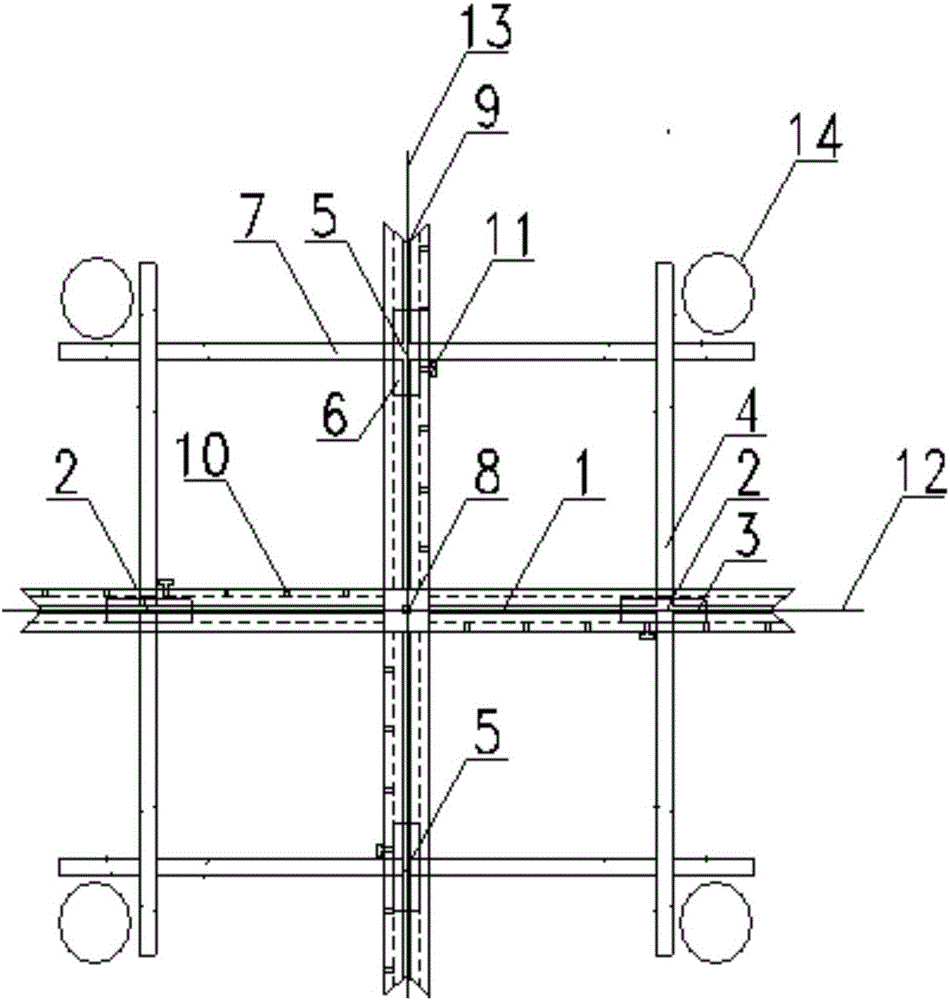

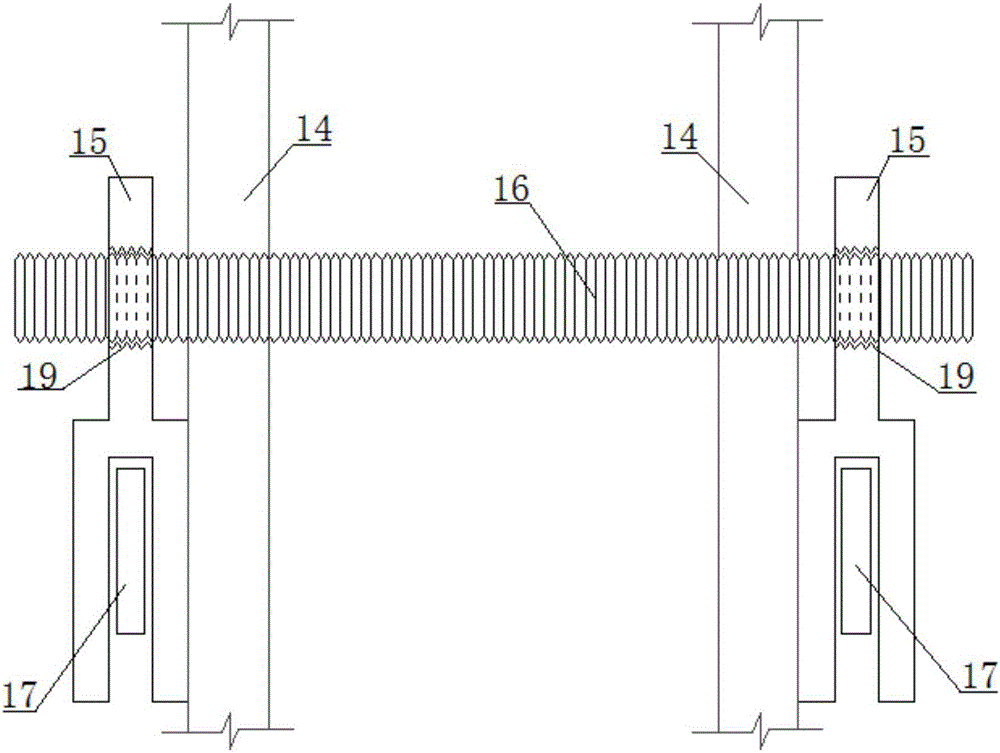

[0039] refer to Figure 1 to Figure 8 As shown, the positioning and strengthening system and method for the reserved steel bars of the cast-in-place connection layer of the prefabricated building in an embodiment provided by the present invention include an axis positioning detection device and an anti-offset reinforcement device. The reserved steel bars 14 are detected and positioned, and the anti-offset reinforcement device is used to reinforce the positioned reserved steel bars 14 to prevent the reserved steel bars 14 from shifting and tilting during the pouring process; wherein,

[0040]The axis positioning detection device includes a cross-shaped frame 1, two sets of transverse slide bar assemblies 2 and two sets of longitudinal slide bar assemblies 5. The cross-shaped frame 1 includes X-axis horizontal bars and Y-axis vertical bars that are vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com