Continuous mixing supply method for acid fracturing fluid

A technology of acid fracturing and acid fluid, which is applied in the direction of earthwork drilling, mining fluid, wellbore/well parts, etc. It can solve the problems of waste of remaining liquid, large investment in equipment, and high labor intensity, so as to save construction fluid and save The effect of controllable equipment cost and dosing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

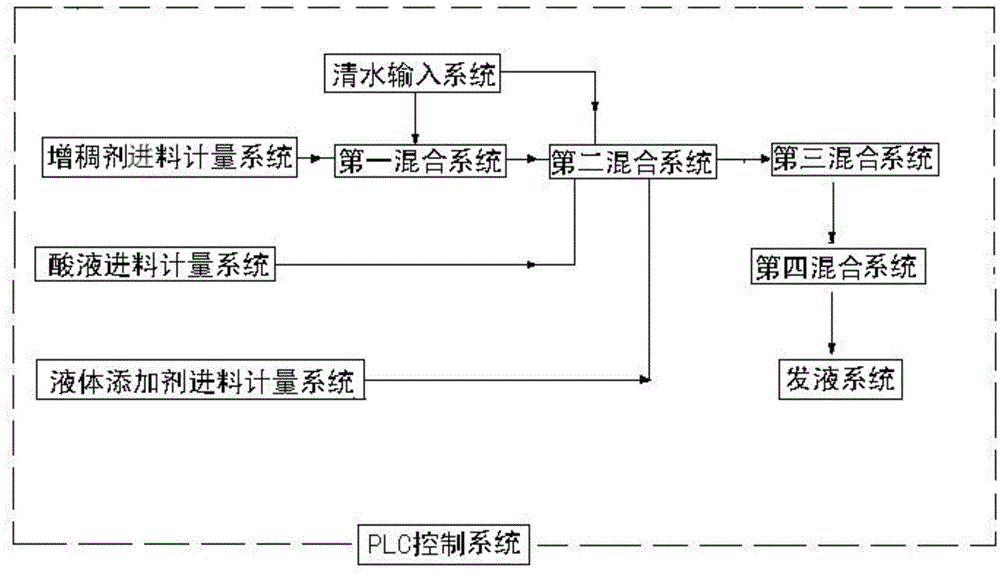

[0046] The method of continuous mixing and supply of acidified fracturing fluid is as follows:

[0047] Step 1, polyacrylamide dry powder is input into the first mixing system through the screw feeding metering device of the thickener feeding metering system, wherein the screw feeding metering device is controlled by the PLC control system, and can be input into the system according to the set water-powder ratio and clean water The input water volume automatically adjusts the dry powder delivery volume; the clean water input system also delivers clean water to the first mixing system, where the flow sensor of the clean water input system feeds back the signal to the PLC control system, and the PLC control system adjusts the proportional control valve to make the clean water The conveying speed and conveying volume meet the specified requirements, so that water can be added while adding thickener dry powder, and the mass ratio of thickener dry powder to water per second is contr...

Embodiment 2

[0052] The method of continuous mixing and supply of acidified fracturing fluid is as follows:

[0053] Step one and step three are the same as embodiment 1,

[0054] Step 2 is: the polyacrylamide premix solution obtained in step 1 is directly pumped into the fourth mixing system through a metering pump, and the metering pump is controlled by a PLC control system, so as to adjust the pumping volume and pump volume of the polyacrylamide premix solution at any time. At the same time, the corresponding acid liquid is sucked from the outside through the two acid-resistant pumps of the acid liquid feeding metering system, and the acid liquid is pumped into the fourth mixing system after passing through the acid-resistant flow sensor and the acid-resistant flow regulating valve on the respective pipelines, controlled by PLC According to the set ratio of the two acid liquids and the signals fed back by the two acid-resistant flow sensors, the system adjusts the input volume and input...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com