Method for manufacturing milling cutter

A manufacturing method and milling cutter technology, which is applied in the field of milling cutter manufacturing, can solve problems such as difficulty in milling cutter recycling, and achieve the effects of no waste of materials, high pass rate, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to achieve the above-mentioned purpose and effect, the technical means and structure adopted by the present invention are hereby described in detail with respect to the preferred embodiments of the present invention. Its features and functions are as follows, so as to fully understand.

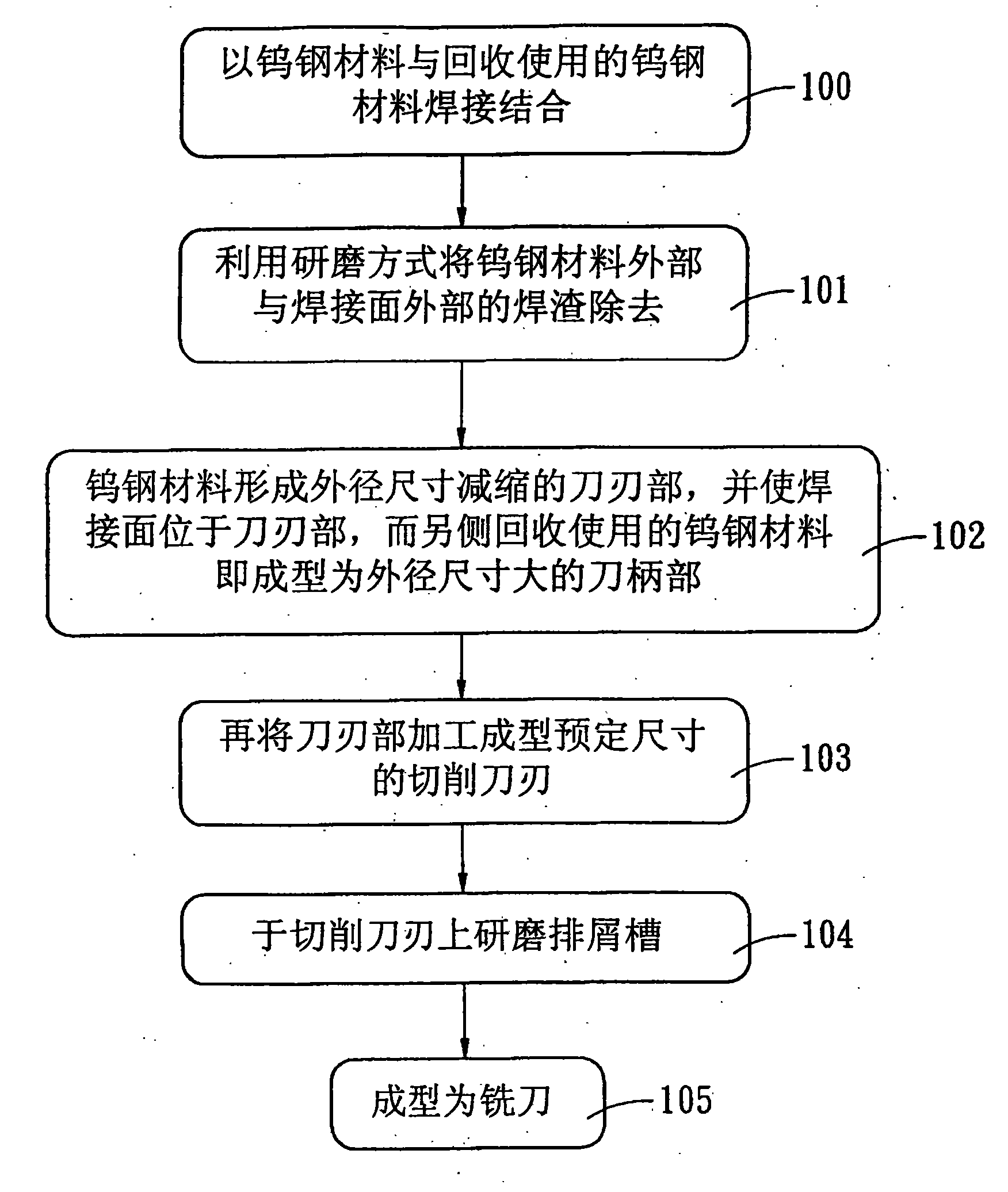

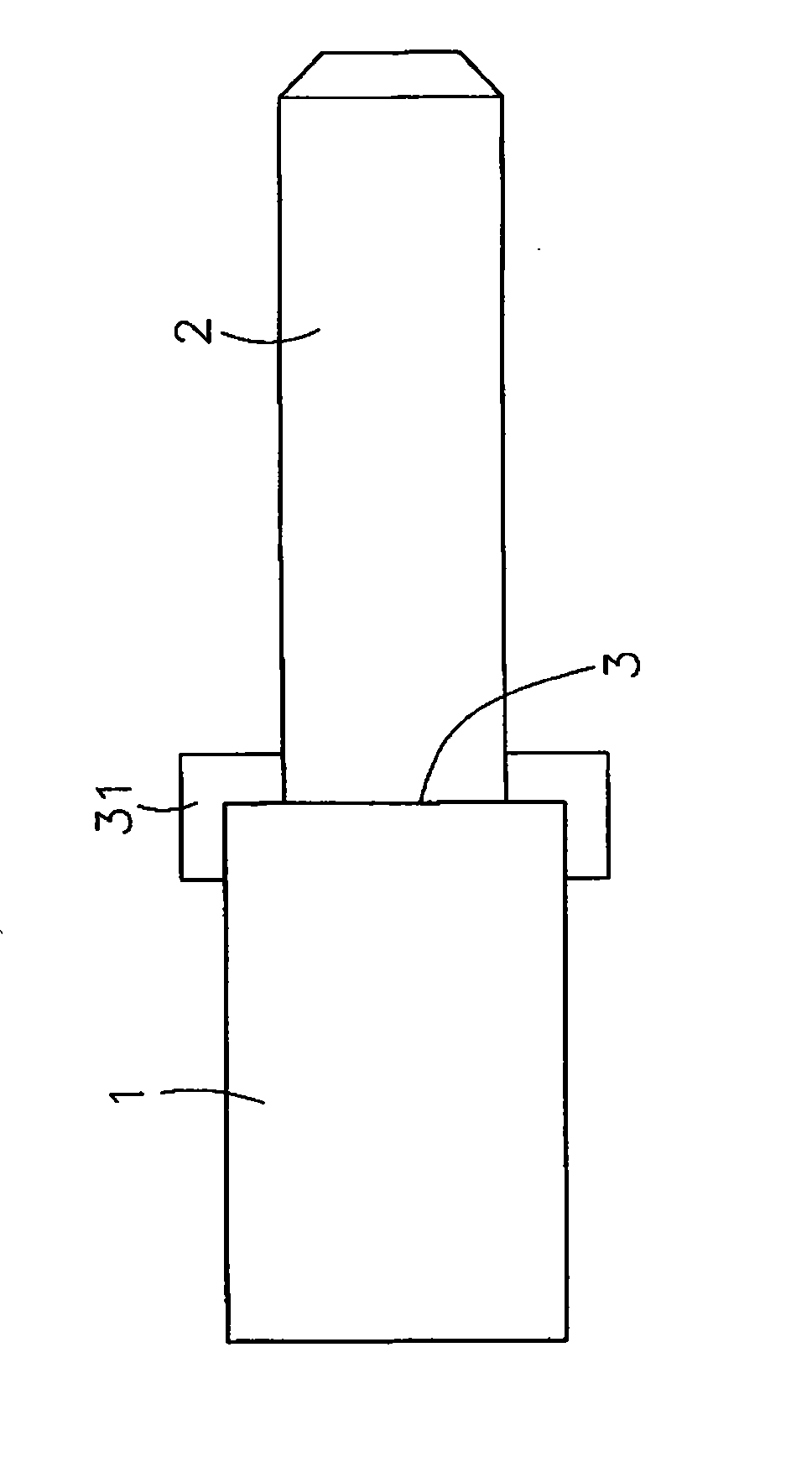

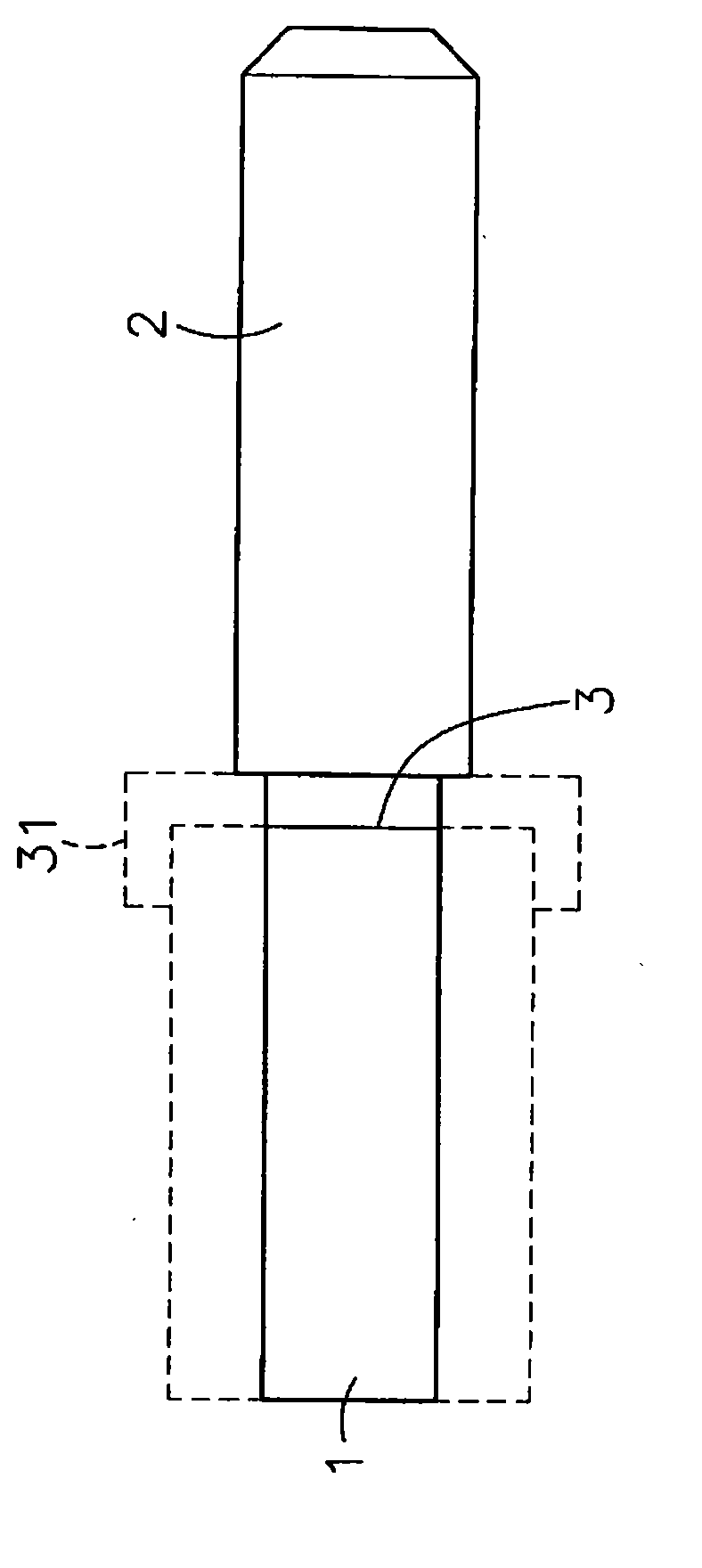

[0025] see figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown is the flow chart of the manufacturing method of the present invention, the plan view after the milling cutter is welded, the appearance plan view after the milling cutter is ground, the plan view of the milling cutter processing and forming blade portion, and the appearance plan view after the milling cutter is formed. It is clearly seen that the milling cutter manufacturing method of the present invention comprises the following steps:

[0026] (100) Provide a brand-new tungsten steel material 1 whose outer diameter is larger than the outer diameter of the recycled tungsten steel material 2 , and wel...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com