Acid fracturing liquid continuous blending supply device

A technology of acidizing fracturing and acid liquid, which is applied in the direction of mixers, fluid mixers, chemical instruments and methods, etc., can solve the problems of difficult acid liquid transportation, long mixing time, and high operating costs, so as to reduce labor costs, distribute The effect of controllable acid precision and high flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the purpose, technical solution and advantages of the present invention clearer, the implementation manners of the present invention will be further described in detail below.

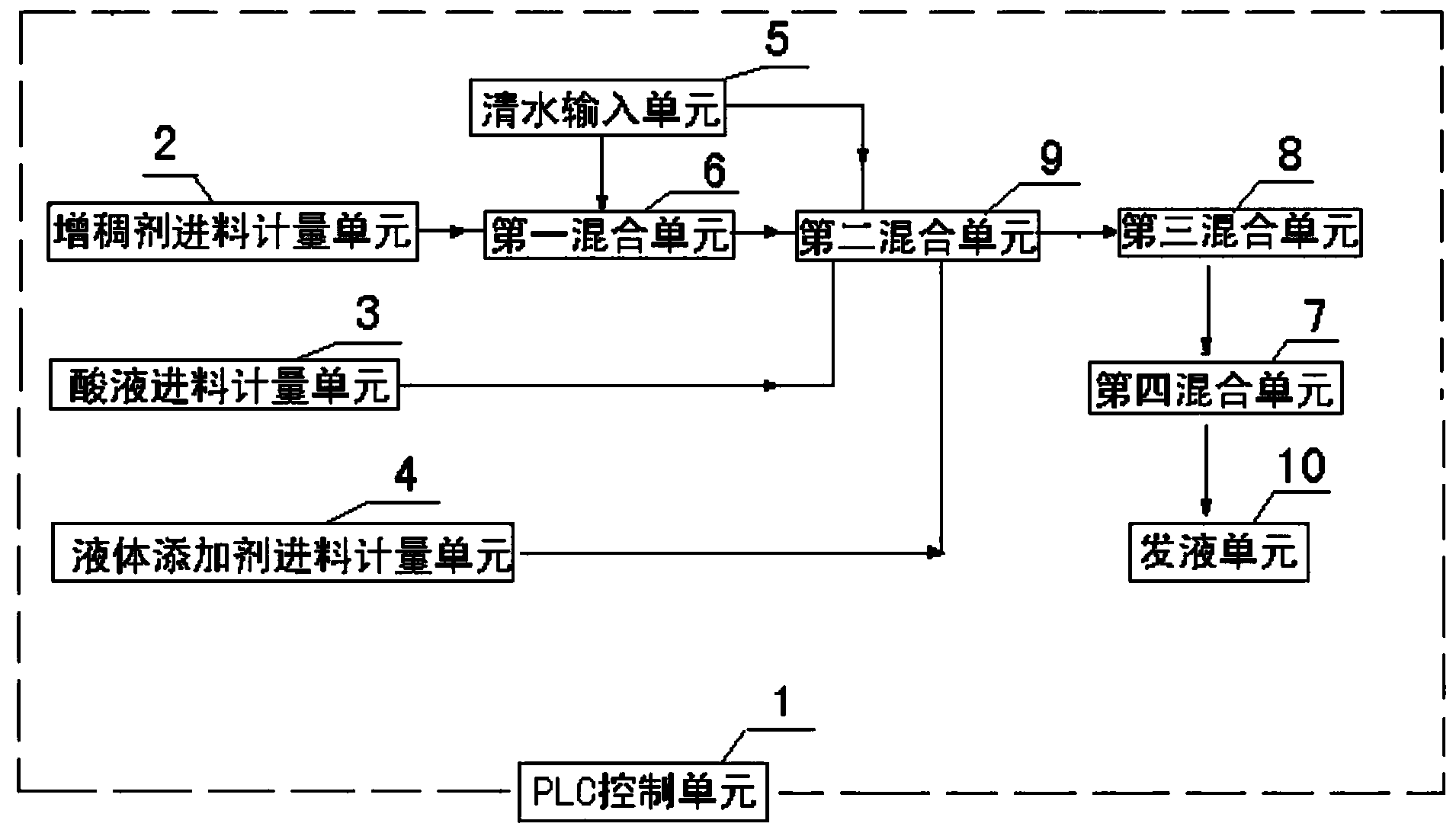

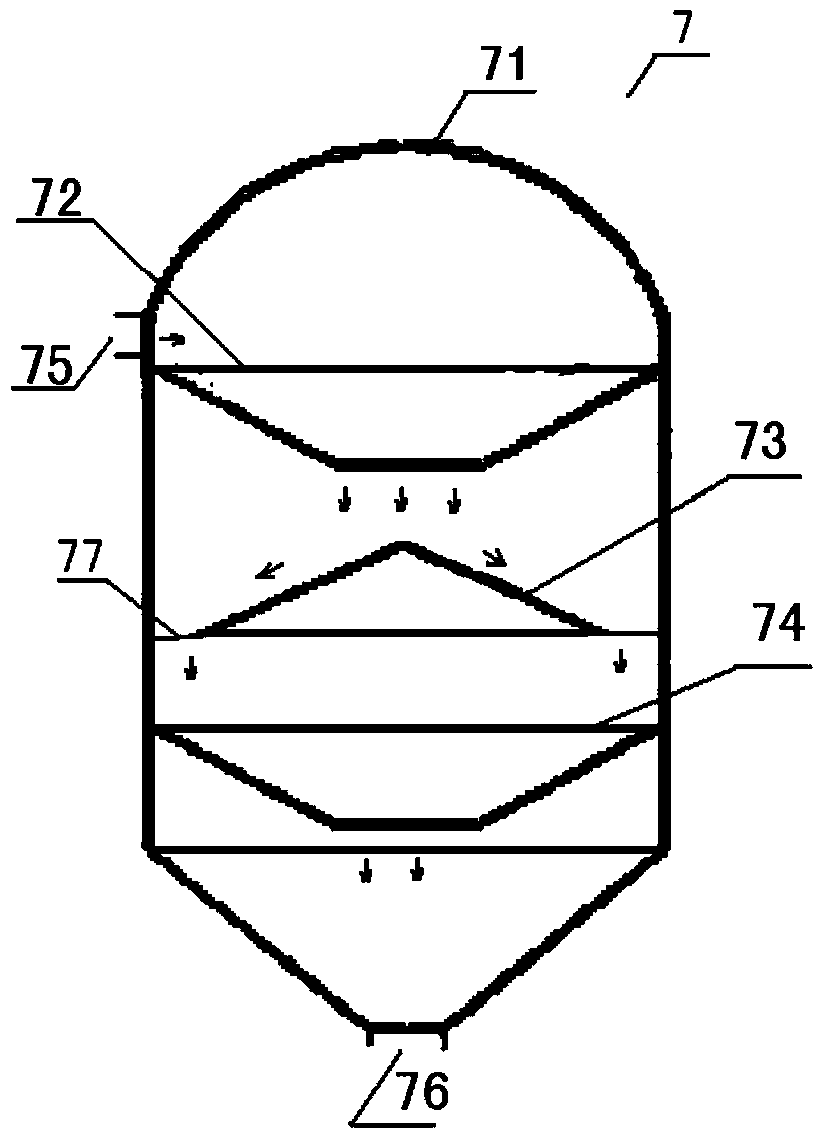

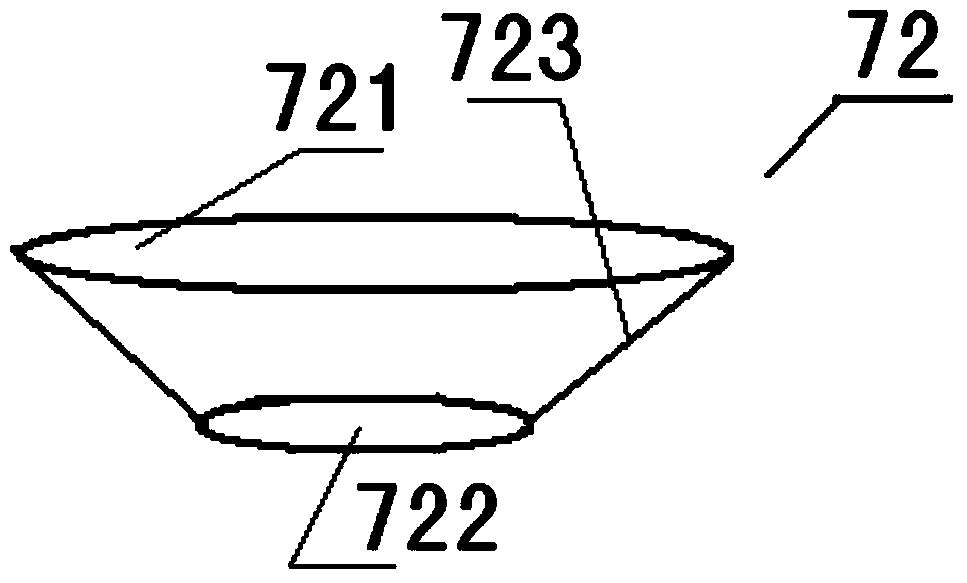

[0032] see figure 1 , which is a schematic diagram of an acidified fracturing fluid continuous mixing device provided in an embodiment of the present invention. The device includes: a PLC control unit 1, a thickener feeding metering unit 2, an acid liquid feeding metering unit 3, and a liquid additive feeding Metering unit 4, clean water input unit 5, first mixing unit 6, fourth mixing unit (mixing tank) 7, third mixing unit 8, second mixing unit 9, liquid sending unit 10, the above units can be installed on a flatbed on the semi-trailer. The above components will be described one by one below.

[0033] The thickener feed metering unit 2 is connected with the first mixing unit 6 and is used for supplying the dry powder or paste thickener to the first mixing unit 6 at a fixed rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com