Quick connector for cables

A connector, fast technology, applied in the direction of transmission element or pulley rope or cable, textile cable, belt/chain/gear, etc., can solve the problems of pulling out the cable, wrong connection, complicated disassembly method, etc. The effect of outputting cables and not wasting materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

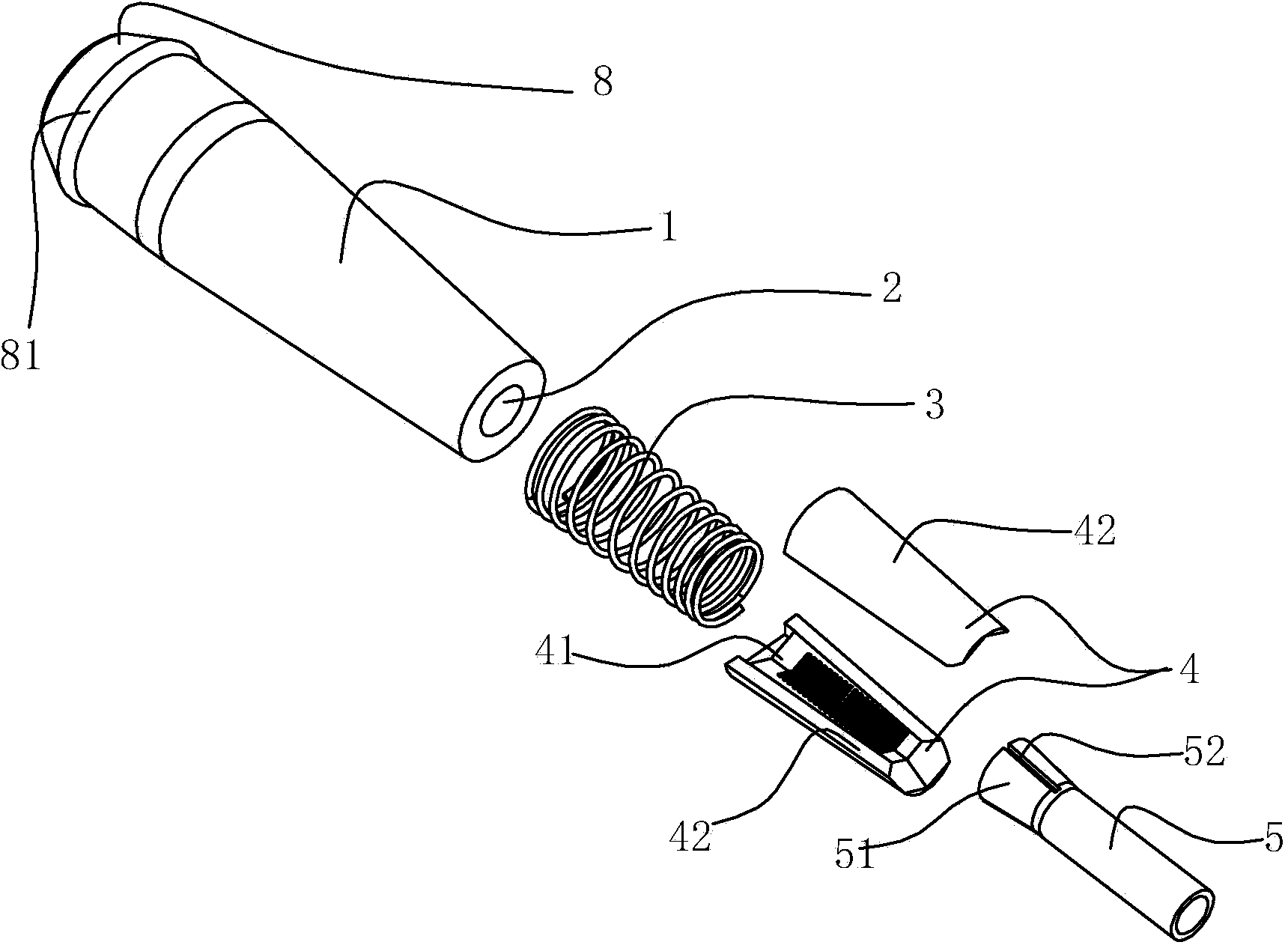

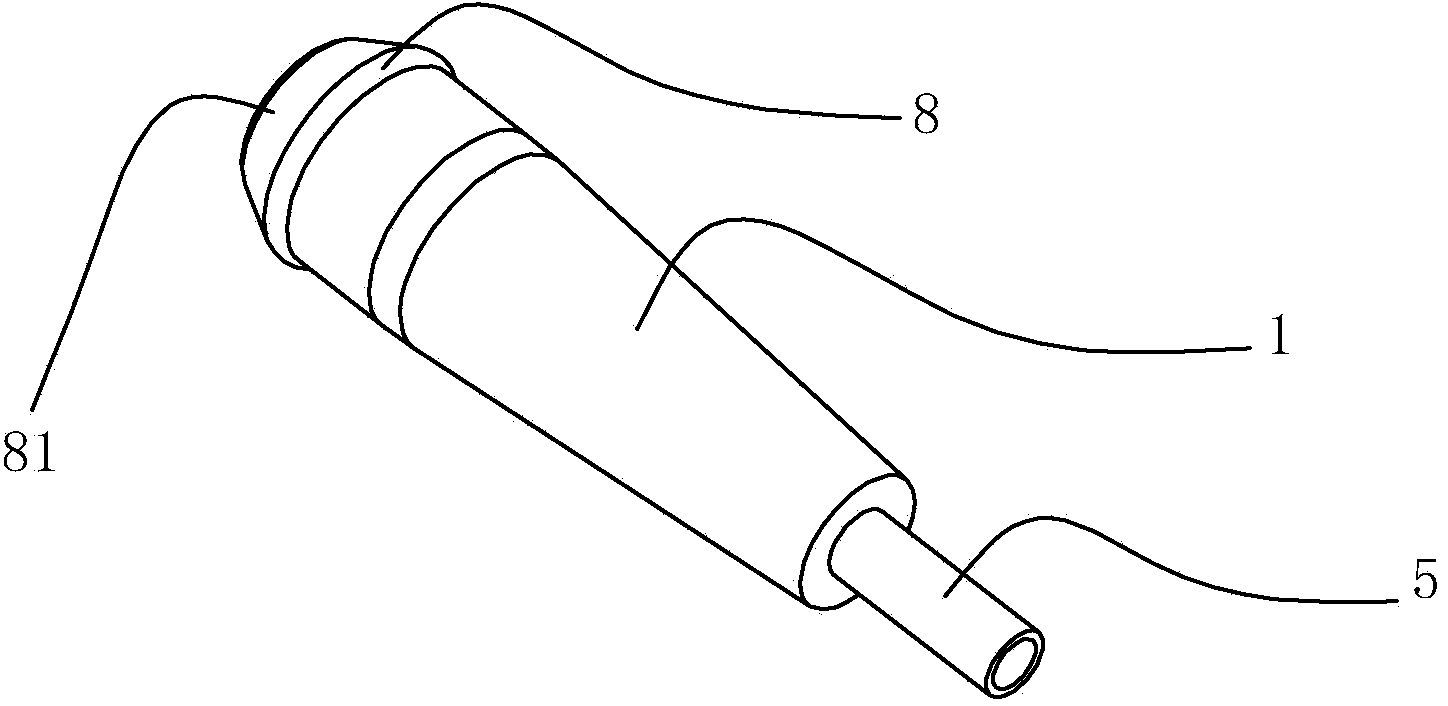

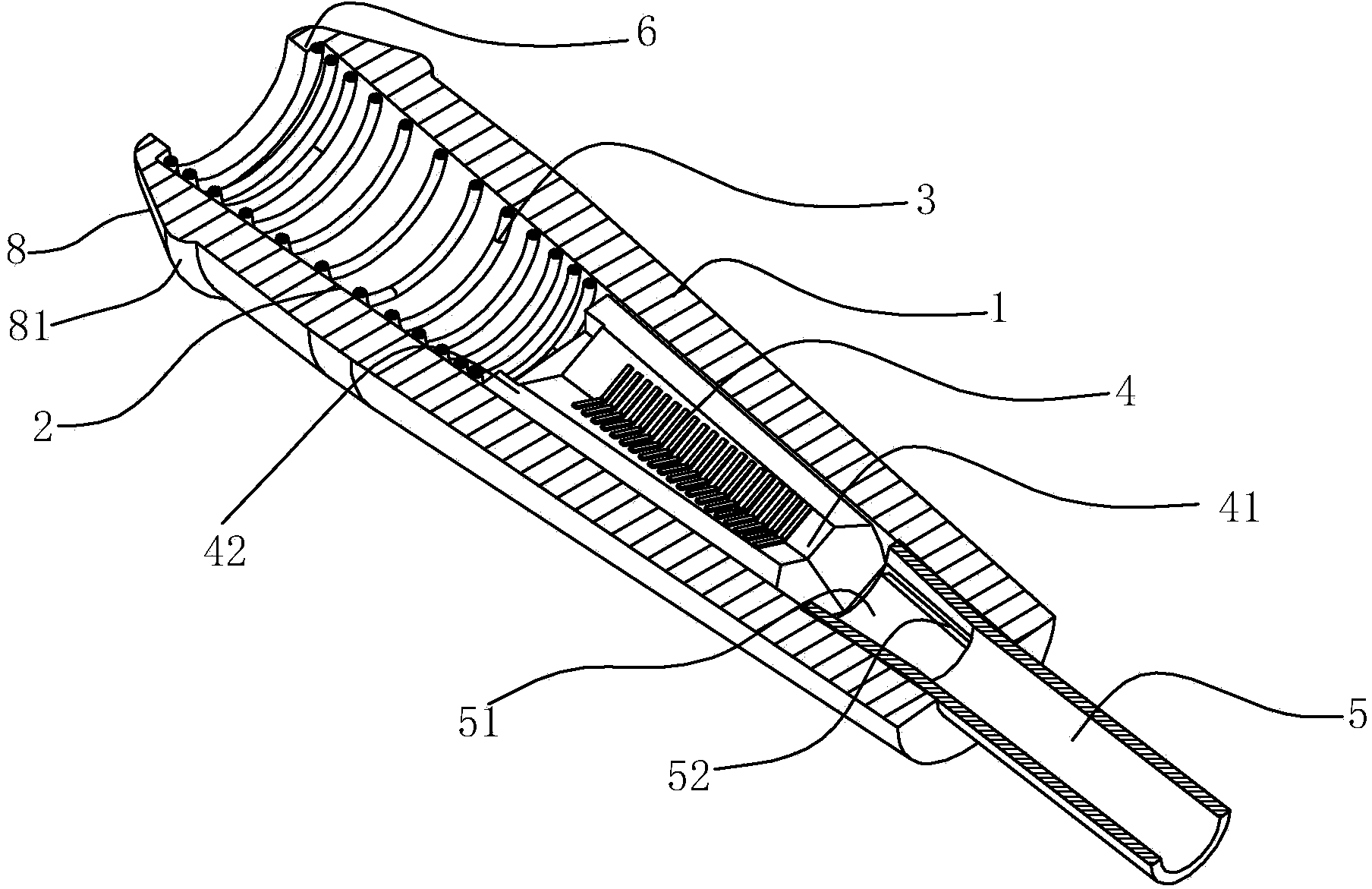

[0022] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, the quick connector for cables in this embodiment includes a sleeve 1 with a tapered through hole 2, and in the tapered through hole 2, the first A spring 3 and a wire clip 4, the first end of the first spring 3 is against the large diameter end wall of the tapered through hole 2, the second end of the first spring 3 is against the first end of the wire clip 4, the described The clamp 4 includes at least two jaws 42, the inside of the jaws 42 has a groove 41 extending along the axial direction of the tapered through hole 2, the sleeve 1 also includes a push tube 5, the first of the push tube 5 One end is located in the small-diameter end of the tapered through hole 2 and abuts against the second end of the clamp 4 , and the second end of the push tube 5 protrudes out of the tapered through hole 2 .

[0023] In order to achieve reliable and firm connection during the cable connection process, in the dire...

Embodiment 2

[0030] Such as Figure 5 , Image 6 and Figure 7 As shown, the difference from the first embodiment is that the second end of the push tube 5 has an outer flange 53 in order to facilitate the operation when the quick connector is used to release the cable and facilitate the user to press the push tube.

[0031] In order to increase the locking degree of the cable in the quick connector and ensure the elastic force for locking the cable, the outer circumference of the push tube 5 protruding from the tapered through hole 2 is provided with a second spring 9 , One end of the second spring 9 abuts against the circumferential end surface of the small-diameter end of the sleeve 1 , and the other end abuts against the outer flange 53 of the push tube 5 .

[0032] The difference from Embodiment 1 during use is that due to the elastic force generated by the second spring 9 on the sleeve 1, the pulling force of the push tube 5 moving to the small diameter end of the tapered through h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com