Pyramid-shaped dot matrix coreboard with transverse bar, panel strips for preparing core and preparation method of coreboard

A technology of pyramids and sandwich panels, applied in the direction of layered products, etc., can solve the problems of small bonding area between the lattice sandwich core and the upper and lower panels, poor structural mechanical properties, and difficulty in interlocking and assembling, and achieves strong overall performance. , The effect of improved shearing performance and convenient interlocking assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

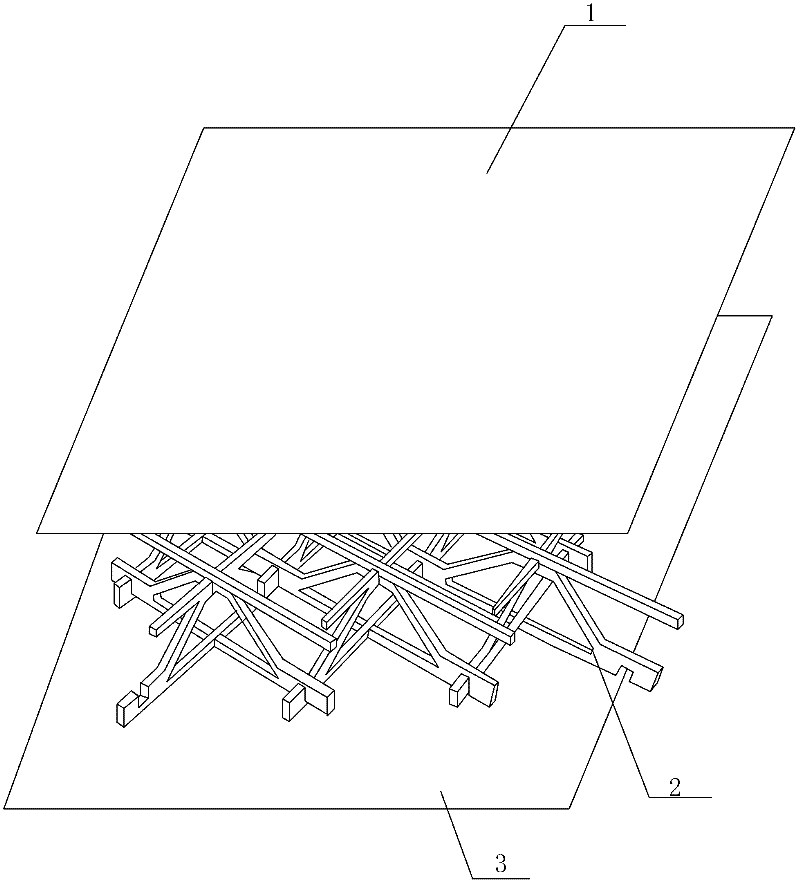

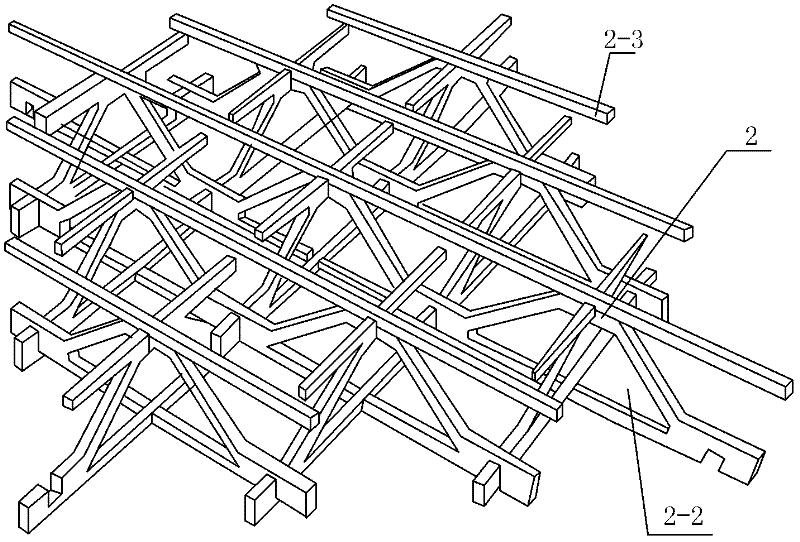

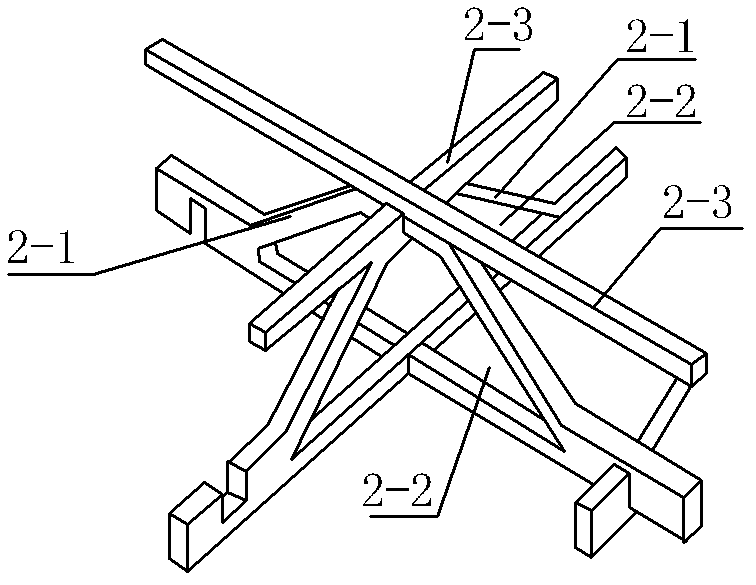

[0014] Specific implementation mode one: as figure 1 As shown, a pyramidal lattice sandwich panel with transverse ribs in this embodiment includes an upper panel 1, a core 2 and a lower panel 3, and the lower surface of the upper panel 1 is bonded to the upper surface of the core 2. connected together, the lower surface of the core 2 is bonded to the upper surface of the lower panel 3, the core 2 is a matrix structure composed of several pyramidal structural units, each pyramidal structural unit has the same structure, each A pyramid structural unit is made up of two vertical boards 2-1, and each vertical board 2-1 structure is identical, and each vertical board 2-1 is the structure that is narrow at the top and wide at the bottom, and two vertical boards 2-1 intersect each other and form a cross Each vertical plate 2-1 is perpendicular to the horizontal plane, the side of each vertical plate 2-1 has a through hole 2-2, and the upper end surface of each vertical plate 2-1 is p...

specific Embodiment approach 2

[0015] Specific implementation mode two: as Figure 4-5 As shown in this embodiment, a kind of molding strip for preparing the core described in Embodiment 1, the molding strip includes an upper molding strip 4 and a lower molding strip 5, and the upper molding strip 4 and the lower molding strip 5 Both are obtained by slotting on a rectangular base, and the side of the upper molding 4 is provided with a first trapezoidal through hole 4-1 and a first inverted trapezoidal through hole 4-2, and each first trapezoidal through hole 4-1 Arranged at intervals with each first inverted trapezoidal through hole 4-2, the upper base of each first trapezoidal through hole 4-1 is provided with a first upper card slot 4-3, and each first trapezoidal through hole 4 -1 has a first notch 4-4 on the lower bottom edge, the central axis of each first upper card slot 4-3 coincides with the central axis of the corresponding first notch 4-4, and the upper fillet 4 There are several second upper car...

specific Embodiment approach 3

[0018] Specific implementation mode three: as Figure 4-5 As shown, the distance d1 between the adjacent two first upper clamping grooves 4-3 of the fillet of the pyramid-shaped lattice sandwich panel core with transverse ribs described in this embodiment is 45.51 mm; The distance d2 between two adjacent first lower card slots 5-3 is 45.51mm. Other components and connections are the same as those in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com