Gas sensor test system

A gas sensor and test system technology, applied in the direction of material resistance, etc., can solve problems such as stable laminar flow in the unfavorable gas sensitivity measurement device, pressure and temperature disturbance of the gas sensitivity measurement device, affecting the test effect of the gas sensor, etc. Good performance, easy adjustment and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

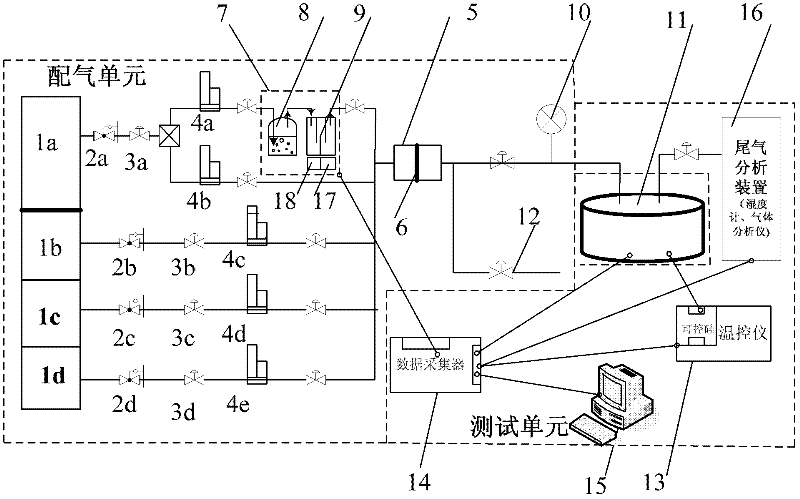

[0034] like figure 1 As shown, this embodiment discloses a gas sensor testing system, including a gas distribution unit, a gas sensitivity measurement device, and a test unit; the gas distribution unit includes an air supply unit 1a, three gas supply units to be tested, and A gas mixing chamber 5 for uniformly mixing air and three gases to be measured, the gas mixing chamber communicates with a gas sensitivity measuring device 11, and is used to input the proportioned gas into the gas sensitivity measuring device through a pipeline. The outlet of the gas mixing chamber 5 is divided into two paths, one path is directly connected to the atmosphere through the valve 12, and the other path is connected to the gas sensitivity measurement device 11, and the pipeline connected to the gas sensitivity measurement device 11 is connected with a pressure gauge 10.

[0035] The three gas supply units to be tested are respectively a hydrogen supply unit, a methane supply unit and a carbon m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com