Steel box girder section design with anti-explosion and anti-impact effects

An explosion impact, steel box girder technology, applied in bridge construction, bridges, bridge parts, etc., can solve the problem of inability to guide the explosion-proof design of steel box girder, the force load and force mode are quite different, and no protection and optimization suggestions are proposed. and other problems, to achieve the effects of good compressive and tensile properties, expanding the force surface and slowing down the speed of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

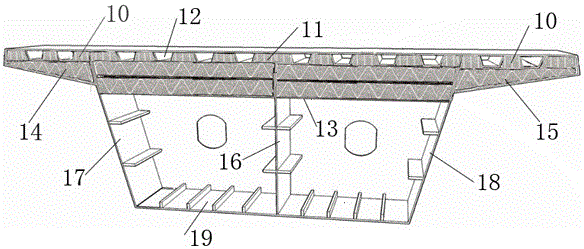

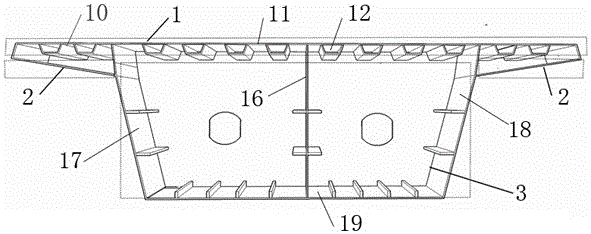

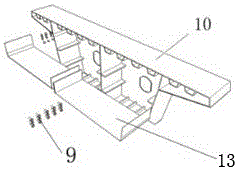

[0038] Such as Figure 1-Figure 5 As shown, a section design of a steel box girder anti-explosion impact, the steel box girder section 10 includes a roof 11, a U-shaped rib 12, a secondary roof 13, a longitudinal diaphragm 16, a first web 17, a second web 18, Bottom plate 19, along bridge type truss-foam aluminum composite member and cross bridge type truss-foam aluminum composite member;

[0039] The top plate 11 is arranged horizontally and a plurality of U-shaped ribs 12 are arranged at intervals on the bottom of the top plate 11, and the space between every two adjacent U-shaped ribs 12 of the plurality of U-shaped ribs 12 is set as the first explosion-proof shock zone 1 , the first explosion-proof shock zone 1 is filled with a single-layer bridge-type truss-foam aluminum composite member flush with the U-shaped rib 12;

[0040] A secondary top plate 13 is horizontally arranged below the top plate 11, the vertical distance between the secondary top plate 13 and the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com