Coal mine transportation system

A transportation system and coal mine technology, applied in the field of coal mine transportation system, can solve the problems of high maintenance costs, high investment costs, noise pollution of high-power diesel engines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The stator frame of the present invention will be described in further detail below with reference to the embodiments given in the accompanying drawings.

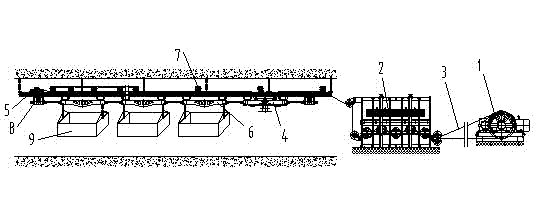

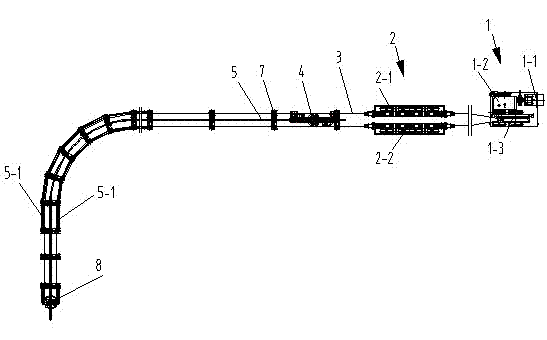

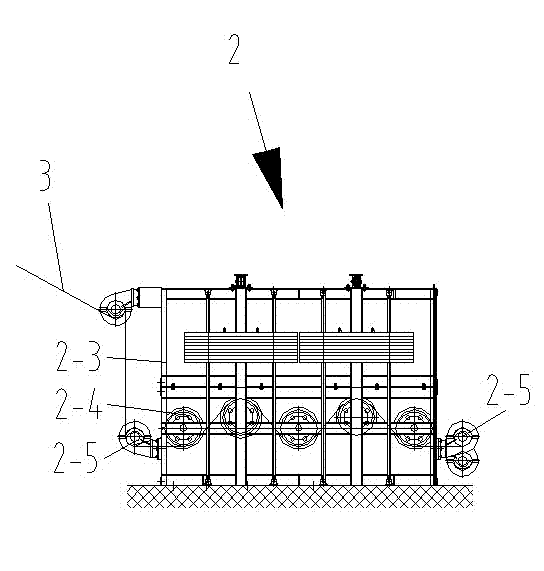

[0020] Such as Figure 1~7 As shown, a coal mine transportation system includes a power system 1, a tensioning device 2, a cable 3, a shuttle car 4, a suspension track 5, at least one lifting device 6, multiple sets of cable limit assemblies 7 and a return rope The wheel 8, the shuttle car 4 and the lifting device 6 are suspended on the suspension rail 5, and are slidingly connected with the suspension rail 5; 5 is fixedly connected, and the rope return wheel 8 is installed on the tail end of the suspension track 5, and the drag cable 3 passes through the power system 1 and the tensioning device 2, and passes through the cable limit assembly 7 and the rope return wheel 8, and pulls The head and the tail of the cable 3 are all fixedly connected with the shuttle car 4, and the shuttle car 4 includes a pulley frame 4-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com