High resolution infrared gas sensor

A gas sensor, high-resolution technology, applied in the direction of instruments, scientific instruments, analytical materials, etc., can solve the problems of difficult high-sensitivity and high-precision gas testing, inability to meet high-precision, high requirements, and low sensitivity of sensor testing , to achieve strong anti-moisture interference ability, improve test sensitivity and accuracy, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be described in further detail below through specific implementation methods.

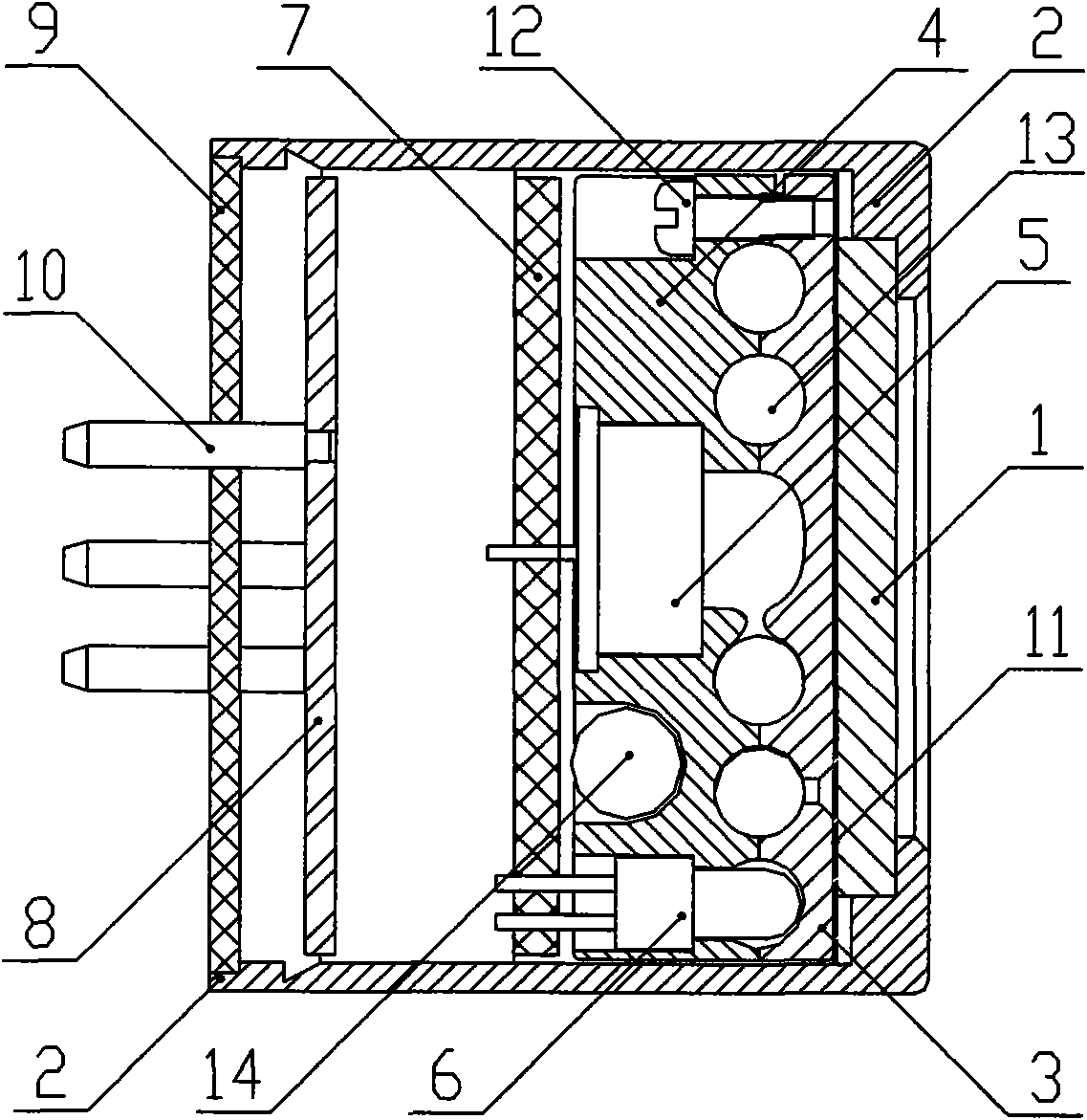

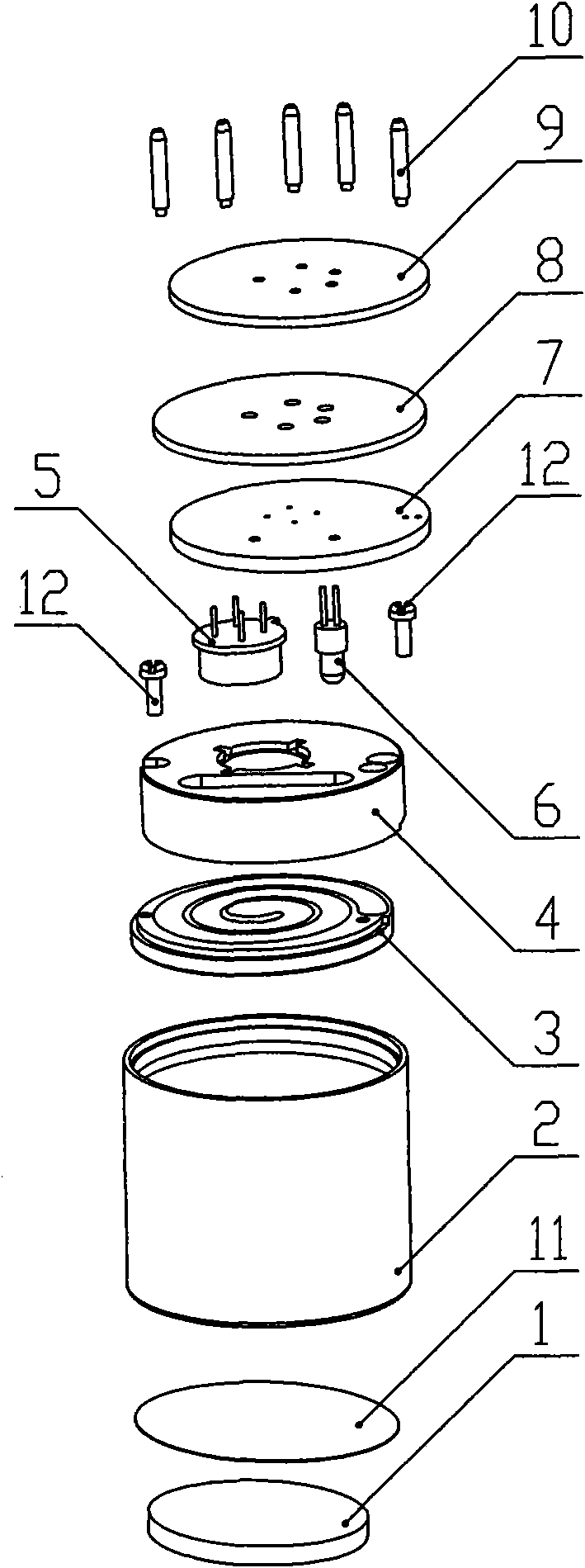

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 As shown, a high-resolution infrared gas sensor comprises an explosion-proof casing 2, an explosion-proof metallurgical powder net 1 arranged at one opening end of the explosion-proof casing 2, an explosion-proof casing cover 9 arranged at the other opening end of the explosion-proof casing 2, and an explosion-proof casing cover 9 arranged at the other opening end of the explosion-proof casing 2. Output pin 10 on 9, infrared gas detector 5 and infrared light source 6;

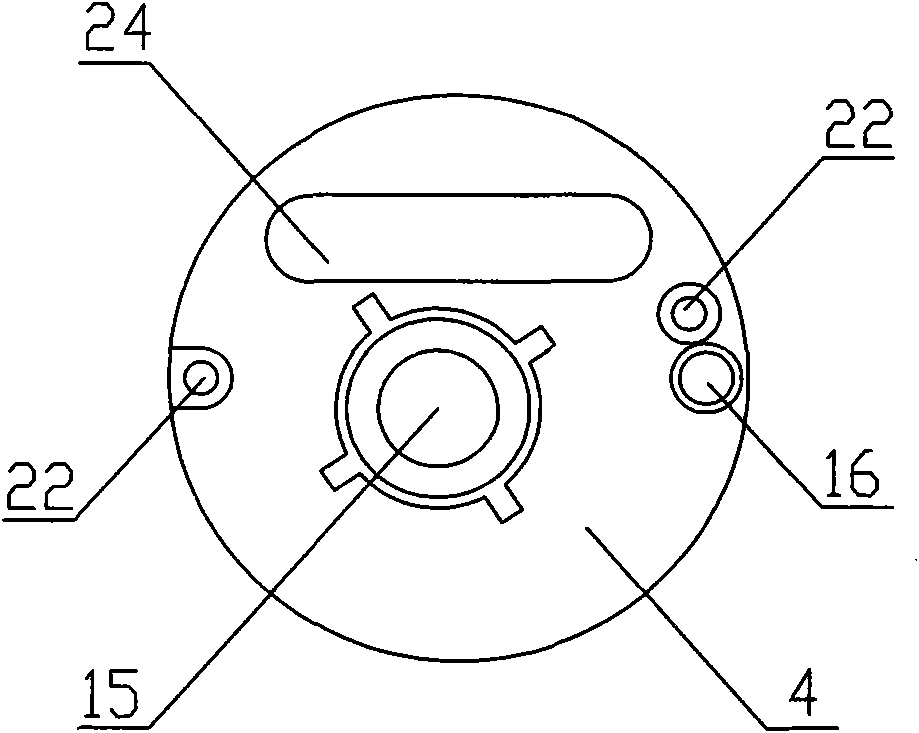

[0030] Wherein, an optical cavity, a signal control and acquisition circuit board 7 and a main circuit board 8 are sequentially arranged inside the explosion-proof housing 2, an optical channel 13 is arranged in the optical cavity, and the optical cavity is close to the explosion-proof metallurgi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com