High durability optical fiber grating wash out sensor

A fiber grating and durability technology, which is applied in the field of quantitative monitoring and scouring sensors, can solve the problems of unsuitable long-term real-time monitoring and complicated operation of traditional methods, and achieve the effect of convenient wiring and saving frequency of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

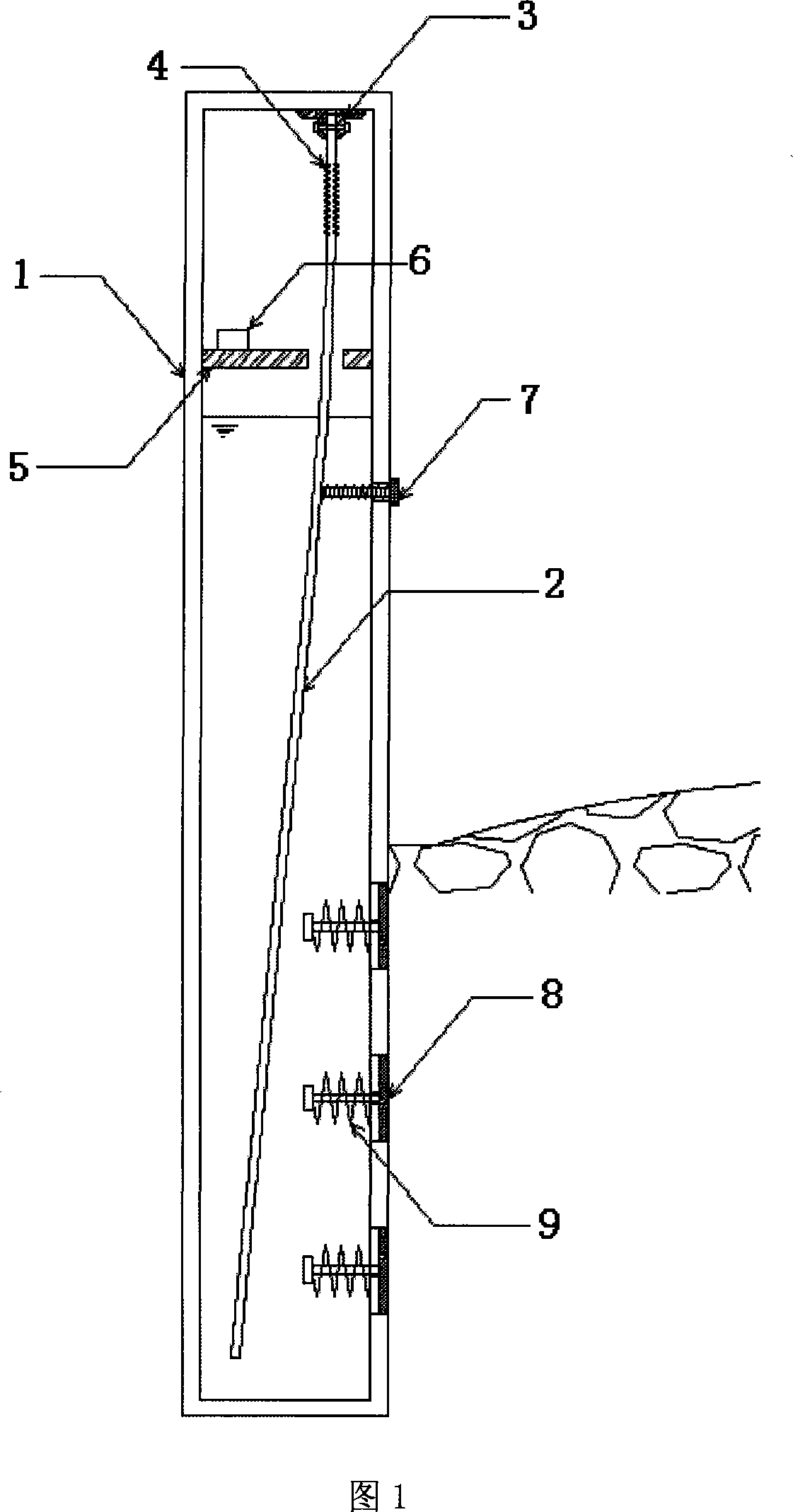

[0043] In conjunction with Fig. 1, this embodiment includes the following structure: a metal casing 1 and a measuring part connected to the metal support 3 on the top of the metal casing 1, which is composed of two fiber gratings 4 attached to the upper and lower surfaces of the FRP equal-strength beam 2, This structure can realize temperature self-compensation while ensuring that the fiber grating monitors the strain; the outside of the measuring part is a protective metal casing; the inner wall of the metal casing 1 is provided with a metal baffle 5, and a small amount of calcium carbide 6 is placed on it for use In order to ensure that the measuring part has sufficient gas protection and improve the sealing of the measuring part; setting the reset element, two options can be selected according to the different ranges: one is a reset bolt 7 under the baffle, and the other is in the metal A pre-compression sleeve is preset on the outer wall of the shell, and the reset element ...

Embodiment 2

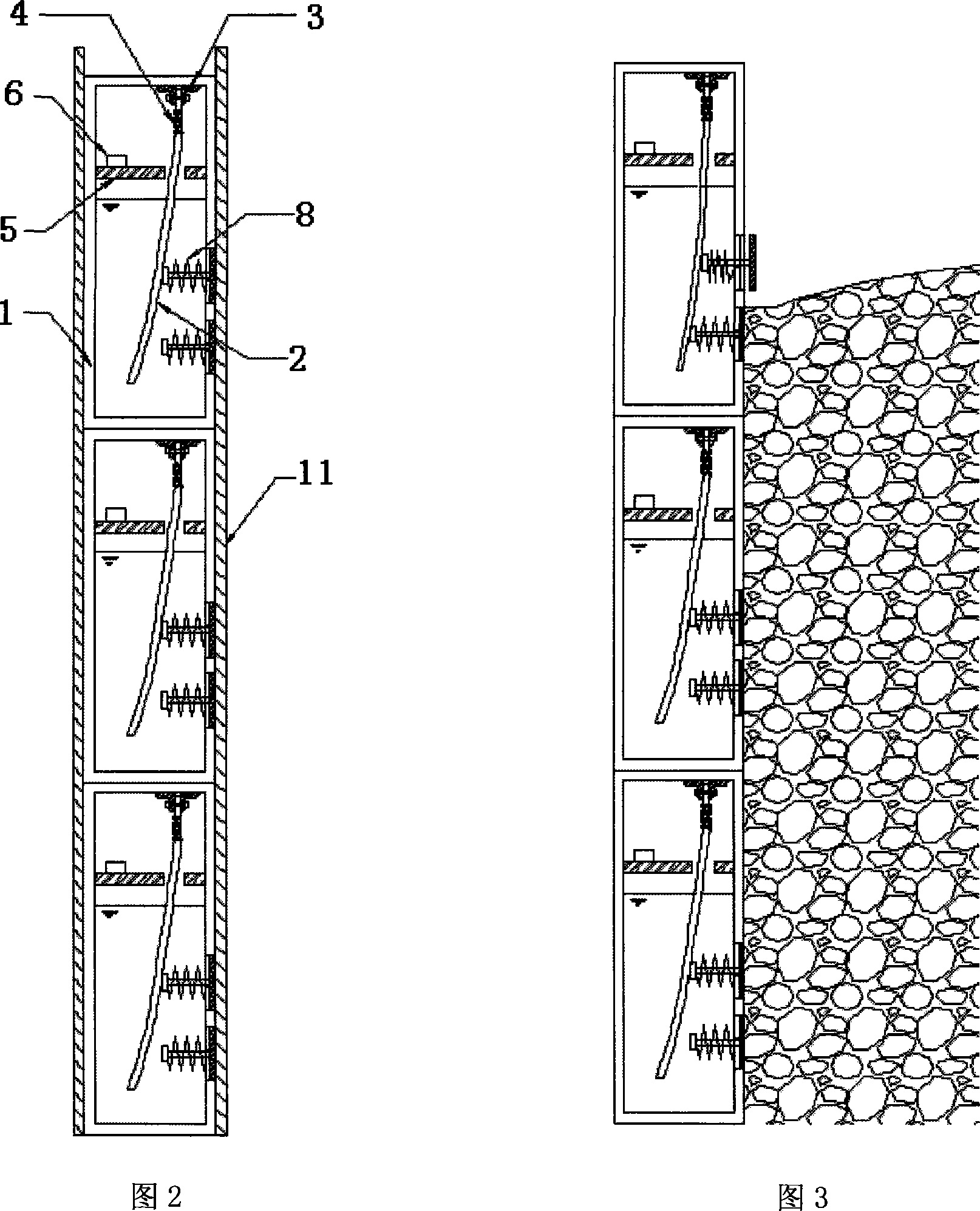

[0051] Referring to FIG. 2 , the basic structure of this embodiment is the same as that of Embodiment 1, except that the reset of this embodiment adopts the second solution, that is, a pre-compression sleeve 11 is preset on the outer wall of the metal casing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com