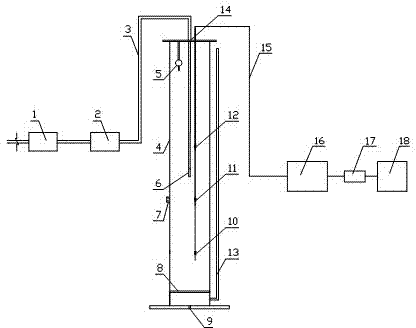

Thick loose rock-soil layer bottom water injection sedimentation deformation analog device and method

A simulation device and rock-soil layer technology, applied in the field of water injection settlement deformation simulation device at the bottom of thick loose rock-soil layer, can solve the problems of sensor moisture resistance, poor waterproof and anti-interference performance, and inability to realize distributed measurement, etc., to achieve real-time online monitoring And long-distance wireless transmission, short test cycle, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

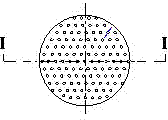

Embodiment 1

[0053] Simulate the loose rock and soil layer with a depth of 120-200 m in a mining area. According to the profile columnar diagram of the core drilled by the geological exploration institute, the test materials are configured in proportion to simulate the thick loose rock and soil layer in a mining area, and the sand ratio of different particle sizes is selected for simulation. experiment material. For the particle gradation experiment of the gravel layer in the loose stratum on site, the gravel layer in the loose rock soil layer D 20 The particle size is 0.5 mm. Select a reasonable allocation of construction river sand particle size gradation in line with D 20 Equivalent particle size model material, model material particle gradation is particle size 0.1-0.25 mm, 0.3-0.5 mm and 1-2 mm sand content ratio is 1:1:8. Model material inhomogeneity coefficient C u 13.31>10, the model material is well graded. The stress of sand grains is less than 3 MPa, and the problem of grain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com