Adjustable explosion relief valve of storage battery

A safety valve, battery technology, applied in battery pack parts, circuits, electrical components, etc., can solve problems such as poor practicability, waste of materials, inconvenience, etc., to achieve strong practicability, prevent explosions, and avoid material waste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] specific implementation plan

[0013] Below in conjunction with accompanying drawing and embodiment the present invention will be further described 。

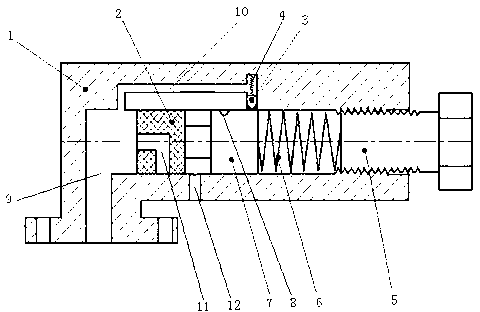

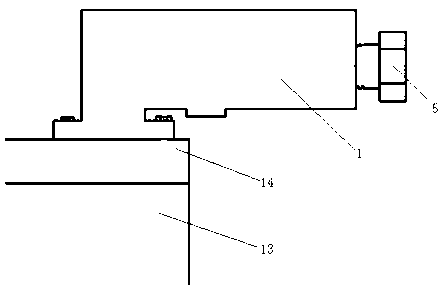

[0014] refer to figure 1 , this embodiment includes a valve body 1, an adjusting nut 5, a pressure spring 6, a piston 7, a sealing ring 2, a latch 3 and a latch spring 4, and the adjusting nut 5 is mounted on the rear end of the valve body 1, and is located One end of the pressure spring 6 in 1 is connected, the other end of the pressure spring 6 is connected with one end of the piston 7, the other end of the piston 7 is connected with the sealing ring 2, and the latch spring 4 is installed in the valve body 1, And fixedly connected with the latch 3, the upper part of the piston 7 is provided with a pit 8 corresponding to the latch 3, and the inside of the front end of the valve body 1 is provided with a first passage 9, and the first passage 9 passes through the second passage 10 In communication with the cavity wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com