PRESSURE adjusting device FOR INK-JET PRINTER and adjusting method thereof

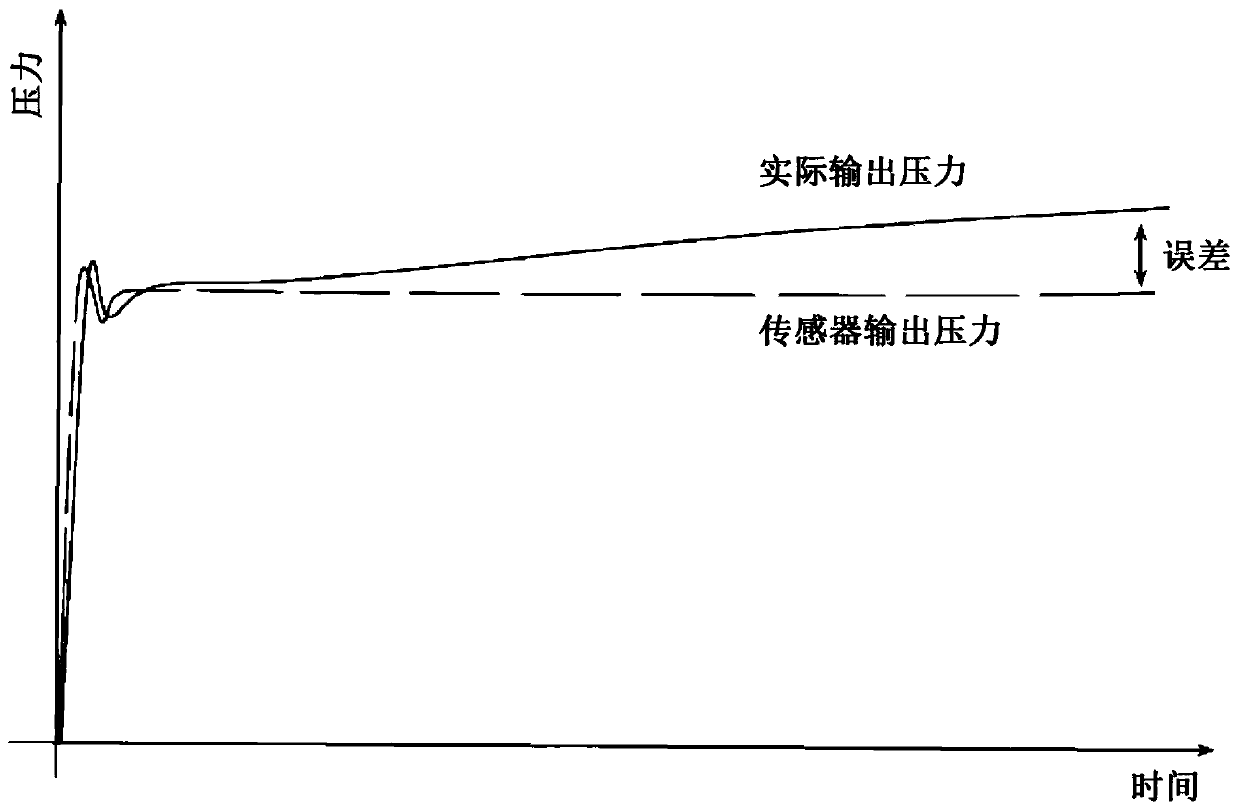

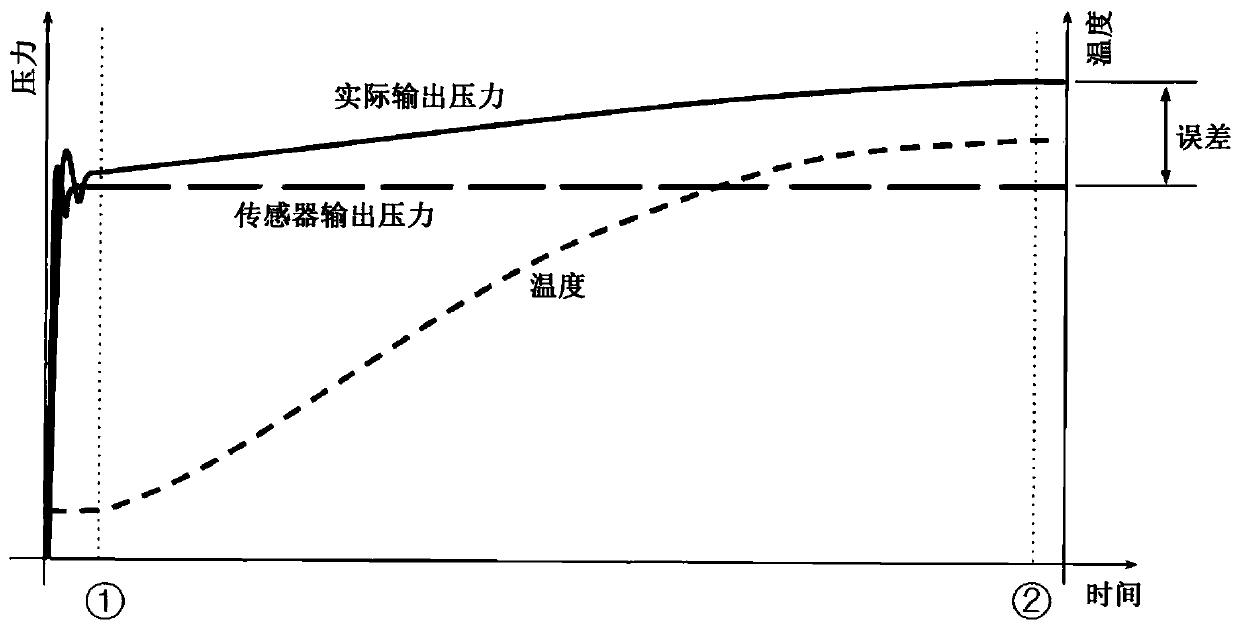

An inkjet printer, pressure regulation technology, applied in measuring device, measuring fluid pressure, printing and other directions, can solve the problems of pressure control offset, error is not large, error, etc., to achieve the effect of precise control and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

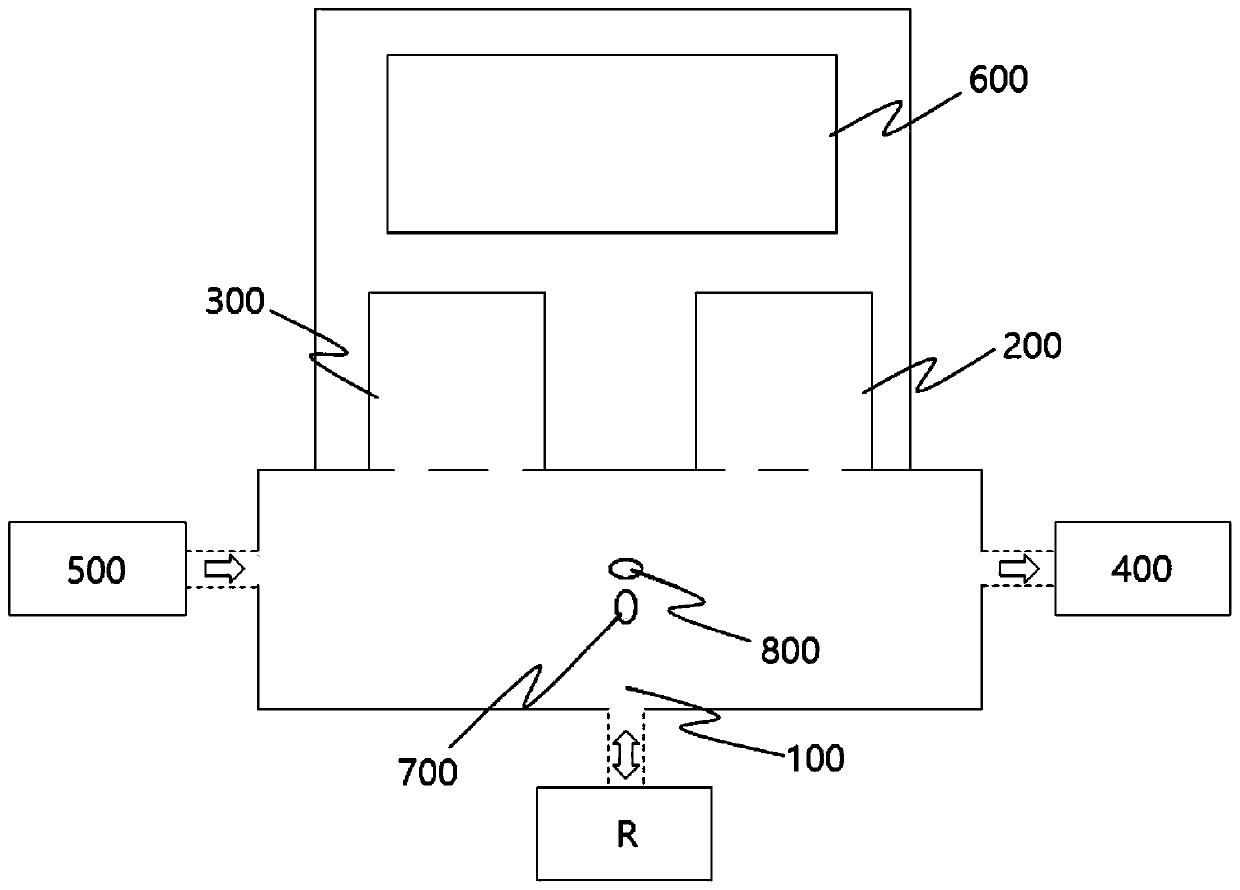

[0025] Embodiments according to the present invention will be described in detail with reference to the drawings.

[0026] However, the embodiments of the present invention can be modified into various other forms, and the scope of the present invention is not limited to the embodiments described below. The shapes, dimensions, etc. of elements in the drawings may be exaggerated for clearer description, and the same elements in the drawings are denoted by the same reference numerals.

[0027] Also, throughout the specification, when a component is referred to as being "connected" to another component, not only the case of "direct connection" but also the case of "electrical connection" with another part therebetween is included. In addition, when a component is referred to as "comprising" or "having" a component, it should be understood that this does not exclude other components, but may also include or have other components, unless explicitly stated otherwise.

[0028] Also,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com