Porous polypropylene modified fiber for antiexplosive concrete

A technology of modifying fiber and polypropylene, applied in the direction of single-component polypropylene rayon, fiber processing, filament/thread forming, etc., to achieve the effect of easy cleaning, meeting special needs, and improving anti-cracking properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

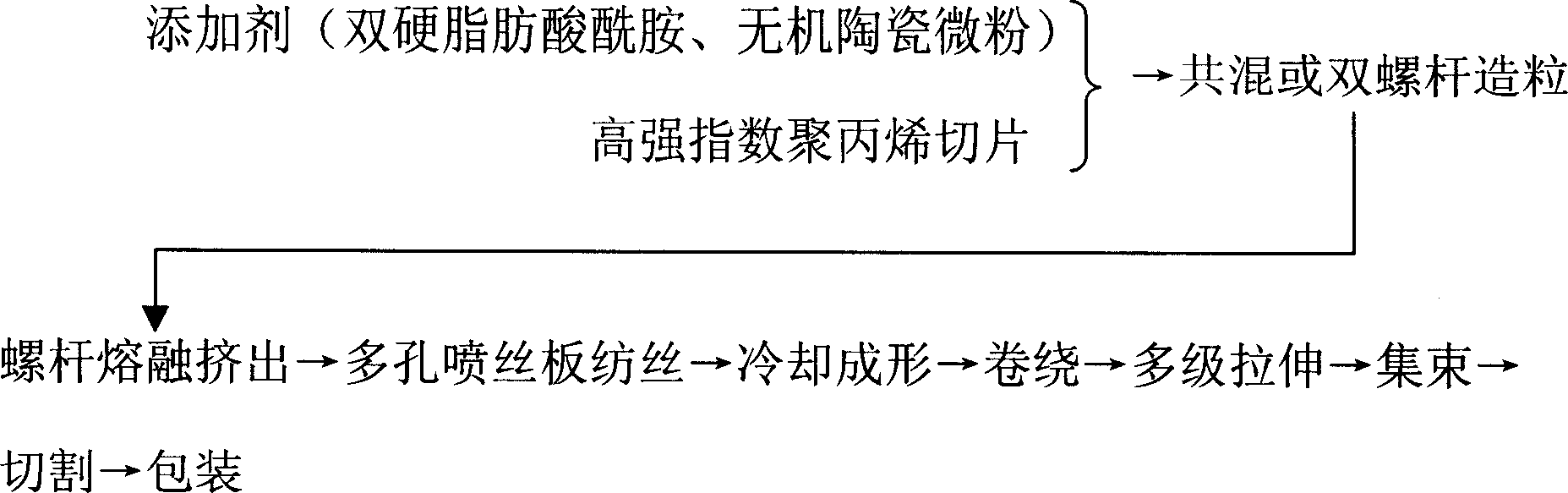

Method used

Image

Examples

Embodiment 1

[0027] Raw material: Polypropylene chips Melt index: 16

[0028] Additive 1: Ethylene bis stearic acid amide

[0029] 0.25% by weight of polypropylene

[0030] Additive 2: Manganese oxide (inorganic ceramic powder)

[0031] 2.6% by weight of polypropylene

[0032] Blending time: 15 minutes, blending method: rotary drum stirring

[0033] Number of spinning holes: Four holes Slit form: Type C: Gap: 0.08mm

[0034] Temperature in each zone of the screw (°C): Zone 1 Zone 2 Zone 3 Zone 4 Elbow flange zone

[0035] 190 205 210 205 198

[0036] Spinning temperature: 210℃

[0037] Blowing speed: 0.38m / s

[0038] Blowing point board distance: 18cm

[0039] Blowing temperature: 20°C

[0040] Spinning and winding speed: 860m / min

[0041] Total post-stretch ratio: 8.8 times

[0042] Hot plate temperature: 56°C

[0043] Hot plate temperature I: 105°C

[0044] Hot plate temperature II: 115°C

[0045] Hollowness: 12%

[004...

Embodiment 2

[0050] Raw material: Polypropylene chips Melt index: 20

[0051] Additive: Ethylene bisstearic acid amine (0.18% by weight of polypropylene chips)

[0052] Additive: Zirconia (inorganic ceramic powder) 2.2% based on the total weight of polypropylene slices

[0053] Blending time: 15 minutes Blending method: rotary drum stirring

[0054] Number of holes: Five holes Slit combination: Four-arc C-type Gap: 0.06mm

[0055] The temperature of each zone of the screw ℃: Zone 1 Zone 2 Zone 3 Zone 4 Elbow flange zone

[0056] 185 190 205 200 198

[0057] Spinning temperature: 205℃

[0058] Blowing speed: 0.40m / s

[0059] Blowing point board distance: 20cm

[0060] Blowing temperature: 18°C

[0061] Spinning and winding speed: 960m / min

[0062] Total post-stretch ratio: 8.4

[0063] Hot plate temperature: 55°C

[0064] Hot plate temperature I: 102°C

[0065] Hot plate temperature II: 110°C

[0066] Hollowness: 15%

[0067] Porosity: 100%

[0068] Tensile strength: 560MPa

[...

Embodiment 3

[0071] Raw Material: Polypropylene Chips Melt Index 25

[0072] Additive 1: Propylene bis stearic acid amide (0.16% by weight of polypropylene chips)

[0073] Additive 2: Zirconia (inorganic ceramic micropowder, 2.0% by weight of polypropylene chips)

[0074] Blending time: 15 minutes Blending method: rotary drum stirring

[0075] Number of holes: seven holes Slit combination: hexagonal arc C-type Gap: 0.04mm

[0076] The temperature of each zone of the screw ℃: Zone 1 Zone 2 Zone 3 Zone 4 Elbow flange zone

[0077] 182 195 205 200 202

[0078] Spinning temperature: 198°C

[0079] Blowing speed: 0.52m / s

[0080] Blowing point board distance: 18cm

[0081] Blowing temperature: 16°C

[0082] Spinning and winding speed: 900m / min

[0083] Total post-stretch ratio: 7.6 times

[0084] Hot plate temperature: 56°C

[0085] Hot plate temperature I: 104°C

[0086] Hot plate temperature II: 112°C

[0087] Hollowness: 16.8%

[0088] Porosity: 97.5%

[0089] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com