Panel mechanized centralized ore-pass upward horizontal cut-and-filling stoping method

A filling mining method and horizontal technology, applied in surface mining, underground mining, special mining, etc., can solve the problems of unsuitable mining of thick and large ore bodies, complex mining process structure, low mining efficiency, etc., and achieve good mining operation safety , The recovery process is simple in structure and the effect of high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

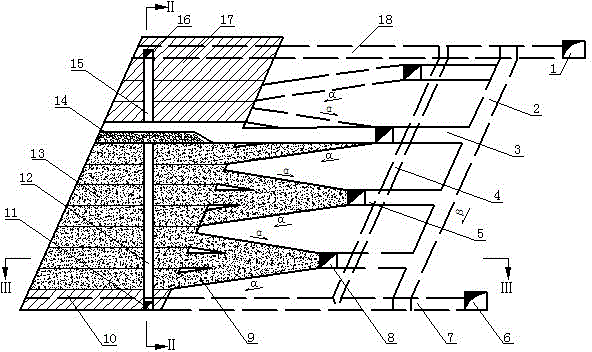

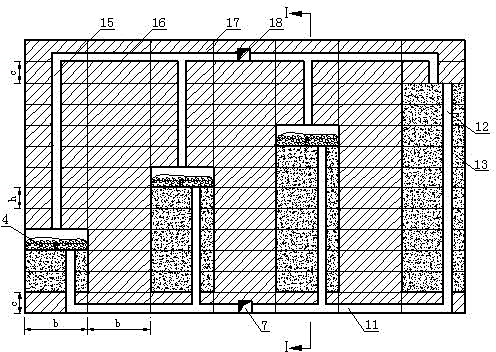

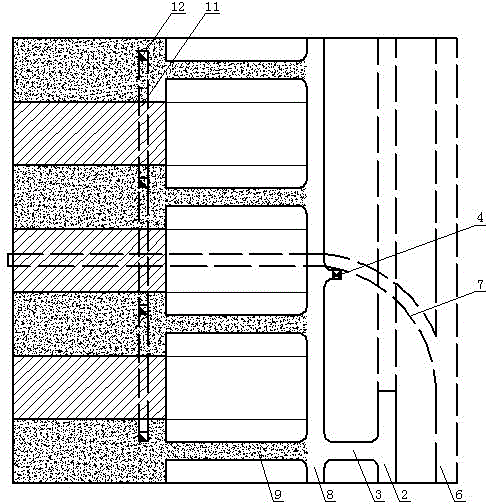

[0029] like figure 2 and figure 1 As shown, the upper stage piercing vein 18 and the lower stage piercing vein 7 are arranged in the center of the panel. The upper stage piercing vein 18 communicates with the ventilation filling shaft 15 in each mine room or inter-column through the ventilation filling shaft connection road 16, and the lower stage piercing Vein 7 communicates with pedestrian water filtration patio 12 in each mine house or inter-column through pedestrian water filtration patio connecting road 11. The panel centralized chute 4 is arranged outside the vein, the panel centralized chute 4 communicates with the upper stage piercing vein 18 and the lower stage piercing vein 7, the panel centralized chute 4 communicates with each chute connecting road 5, and each chute connecting road 5 communicates with the Respectively corresponding subsection level lanes 8 are connected.

[0030] Mechanized mining is adopted, the mining room is recovered first, and then the inte...

Embodiment 2

[0040] The total number of mine rooms and inter-columns arranged at intervals is 5 to 6, and the width of mine rooms and inter-columns is b Both are 12~15m, and the layered height of mine room and inter-column h Both are 6~8m.

[0041] Described filling material 13 is respectively: when mining house mining, use high-strength filling material 13 to fill, and the lime-sand ratio of high-strength filling material 13 is 1: (8 ~ 10); Filling material 13 is used for filling, and the gray-sand ratio of medium-strength filling material 13 is 1: (12~15).

[0042]The slope β of the external ramp 2 is 15-18%.

[0043] The slope α of the stope connecting road 9 is 16-18%.

[0044] The height c of the top column 17 and the bottom column 10 are both 6-8m.

[0045] The beneficial effect that this specific embodiment has compared with prior art is:

[0046] ①Large production capacity

[0047] In this specific implementation mode, the production of the ore body in the stage is organized ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com