Separation-wall-free initiative top filling wall type filling mining method

A backfill mining method and separation wall technology, which is applied in the fields of backfill, ground mining, mining equipment, etc., can solve the problems of not being able to play the active bearing role of the backfill body, affecting the mining safety and resource recovery, and the complex construction process of the diaphragm wall. Conducive to low-consumption mining, solving the problem of filling and topping, and shortening the mining cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in various ways defined and covered below.

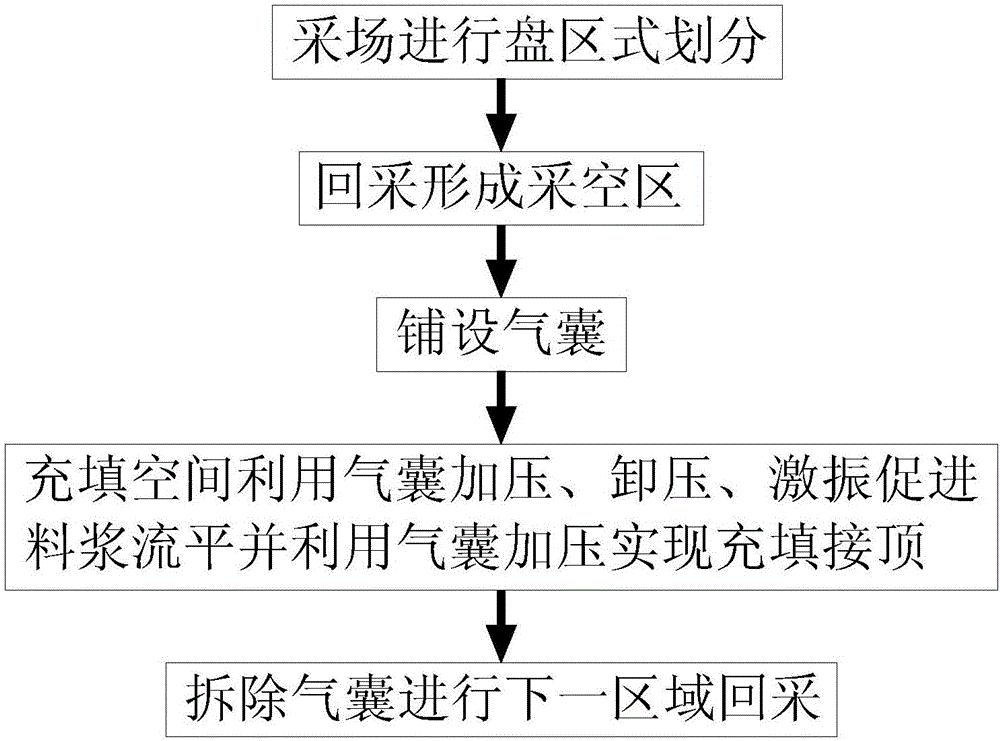

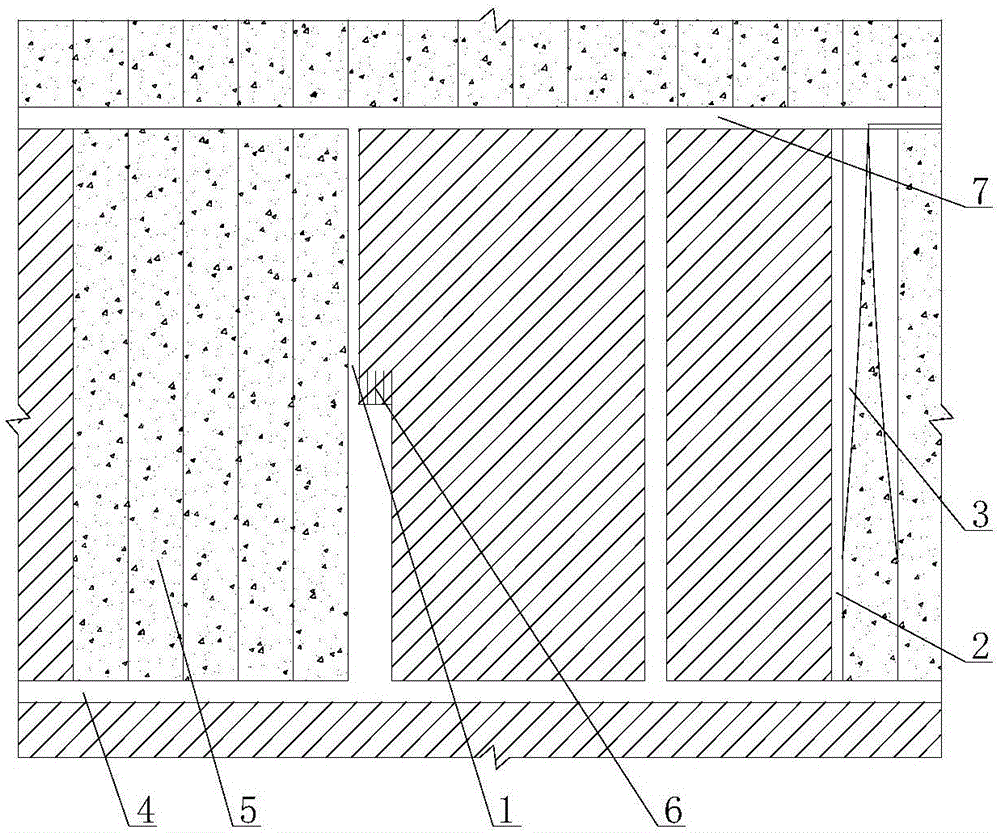

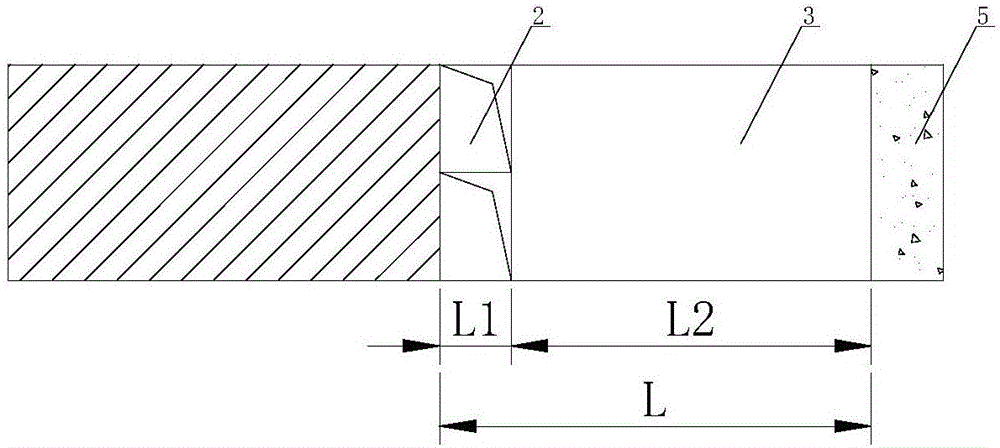

[0026] figure 1 It is a block diagram of the implementation steps of the non-separation wall active top wall filling mining method in the preferred embodiment of the present invention; figure 2 It is a structural schematic diagram of the active top-wall filling mining method without a partition wall in a preferred embodiment of the present invention; image 3 is a schematic diagram of the space partition of the preferred embodiment of the present invention; Figure 4 It is a schematic diagram of the recovery of the preferred embodiment of the present invention.

[0027] Such as figure 1 with figure 2As shown, the non-dividing wall active top wall filling mining method in this embodiment includes the following steps: a. Carry out panel-type division of the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com