Continuous stoping and filling mining method for gently inclined medium-thick ore body

A kind of technology of gently tilting, medium-thickness and mining method, applied in the fields of backfill, mining equipment, earth-moving drilling, etc., it can solve the problems of unfavorable mine safety production, high ore loss rate, long operation line, etc., and achieve good backfilling effect. , The effect of high degree of mechanization and less cutting engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0040] The ore body in the southeast of the Chambishi Copper Mine is layered and layered. The dip angle of the ore body is 20-30°, the thickness is 10-16m, and the length of the ore body along the strike is 755-890m. The surrounding rocks of the hanging wall and footwall of this mining area are all quartzite, which has good stability, and the mining of the ore body is less affected by groundwater, and the engineering geological conditions are of simple and medium types.

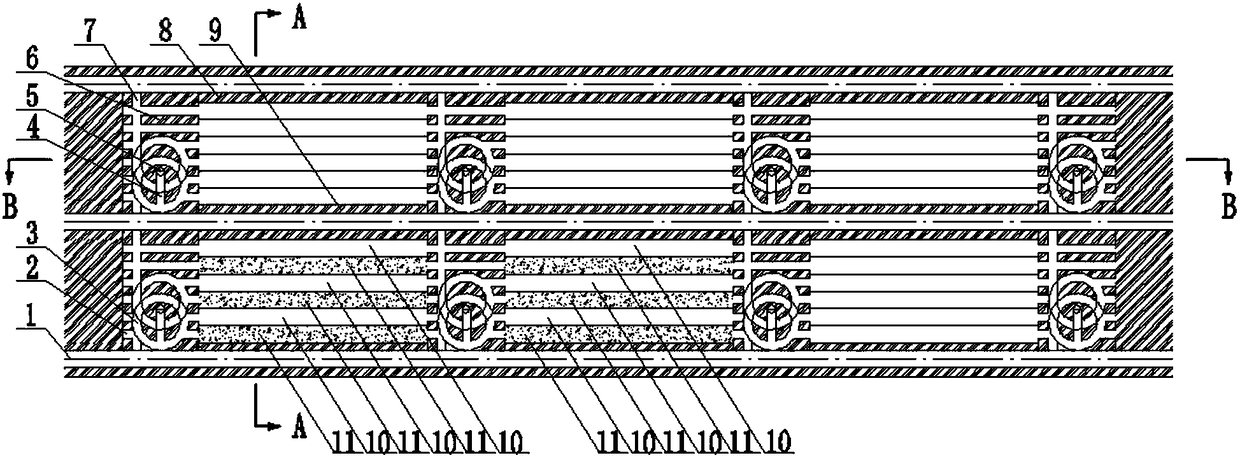

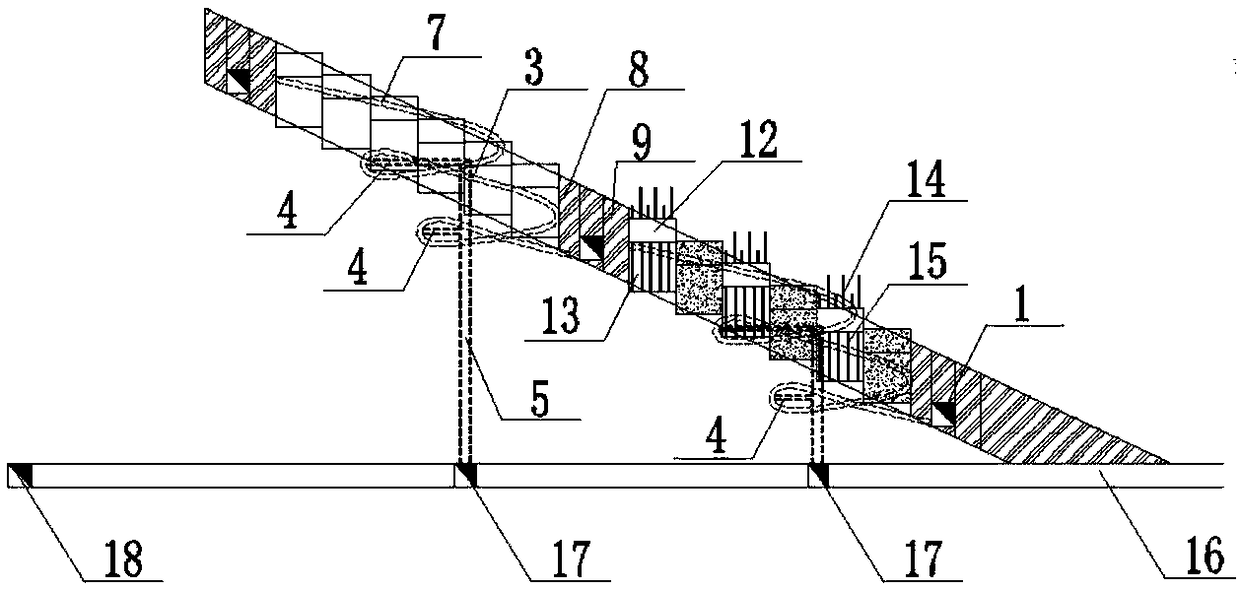

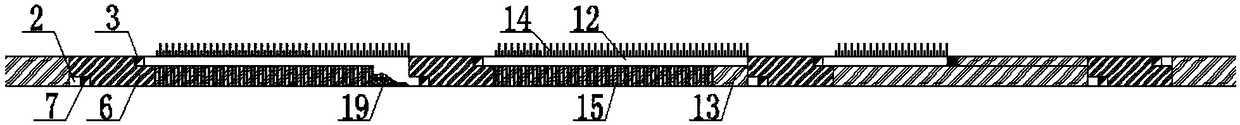

[0041] Acquisition and cutting: such as figure 1 , 2 As shown in and 3, the gently inclined medium-thick ore body is divided into mining units, and the ore bodies in the same mining unit are divided into strips along the strike, that is, the strips in the mining unit are divided into one-step stope 11 and two-step stope 10. Every 12 stopes are used as a recovery unit, and a spacer 6 is left in the middle of each recovery unit. On the spacer 6, there are ramp bends 3, ramp straights 7 and production area chut...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com