Method for reconstructing floor limestone aquifer into natural-artificial composite integrated aquiclude

A technology of artificial composite and water-proof layer, applied in the field of mining or quarrying, can solve the problems of complex geological conditions of hydrology and engineering, and achieve the effect of improving the critical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

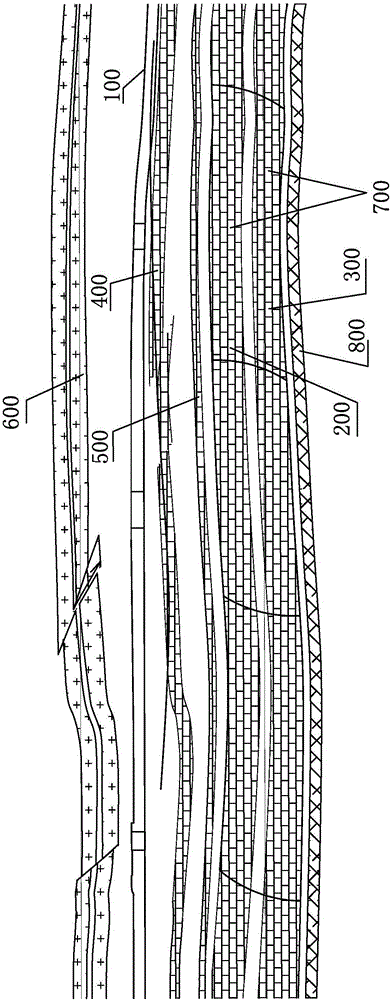

[0032] Such as figure 1 As shown, the technical scheme of the present invention is specifically described below by taking the implementation of the method of transforming the floor limestone aquifer of the present invention into a natural and artificial composite complete water-resisting layer on a certain working face in a mining area as an example.

[0033] The method for transforming the floor limestone aquifer into a natural and artificial composite complete water-resisting layer comprises the following steps:

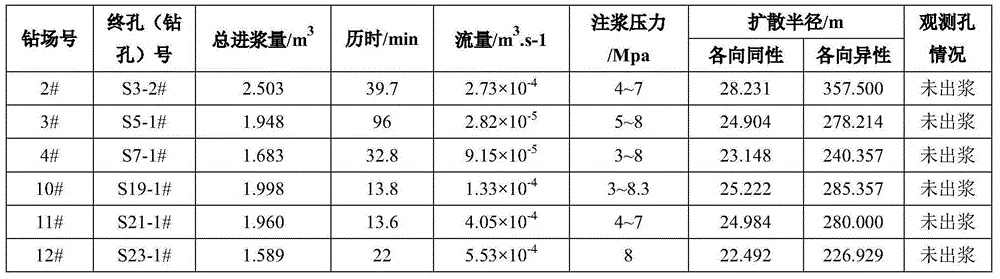

[0034] ① Research on the prevention and control of limestone water damage in the coal seam floor 100 in the mining working face, that is, analyze the threat caused by the limestone aquifer to the mining of 1 coal 600, and determine the damage depth of the coal seam floor 100 through simulation, calculation, and actual measurement analysis, and Therefore, it is determined that the 3rd ash 200 and 4th ash 300 in the upper section of Taihui are used as the target laye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com