Method for preventing and treating separation layer water of top plate of coal face

A coal mining face and roof delamination technology, applied in drainage, mining equipment, earthwork drilling and mining, etc., can solve the problems of affecting the production efficiency of mining areas, occupying roadways, and low drainage efficiency of drainage holes, so as to avoid water damage from delamination Effects of Accidents, Continuous Safety Recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited thereto.

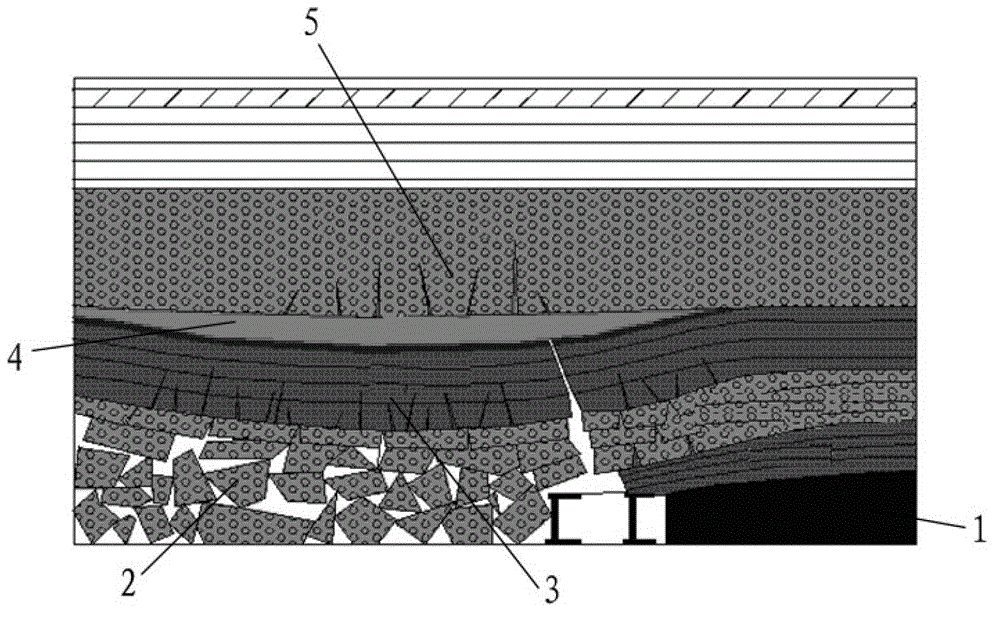

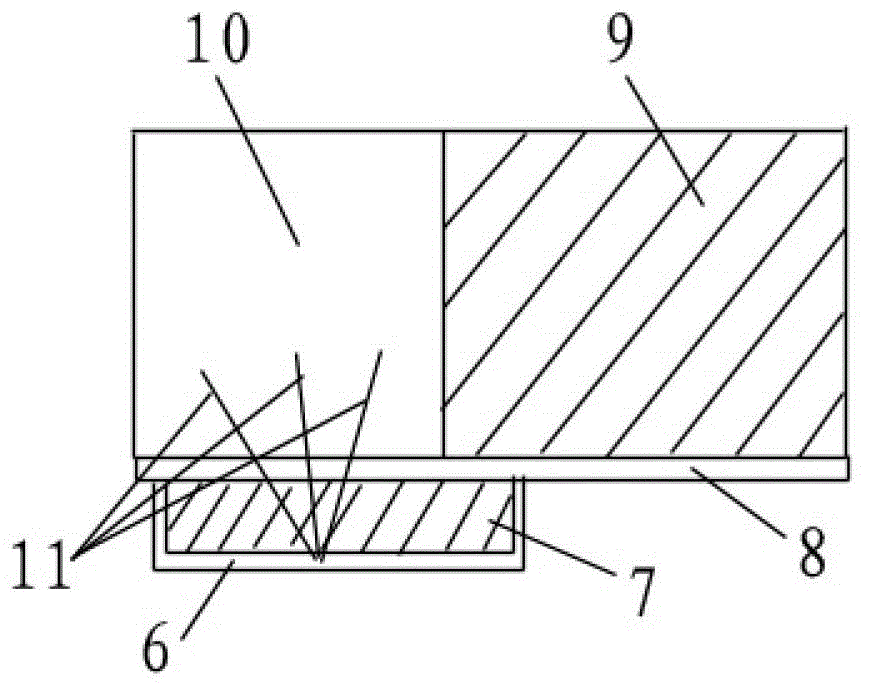

[0024] Such as figure 2 As shown, in the first step, the drainage roadway 6 is constructed along the mining direction on one side of the coal mining face. Preferably, when the horizontal heights on both sides of the working face are different, the drainage roadway 6 is located at the lower side of the working face. side. And the said drainage lane 6 is located on the outside of the lane 8 (return air lane or transportation lane) on this side of the working face, and there is a predetermined distance from the lane 8, so that the drainage holes for subsequent construction will pass through the water-conducting cracks. The collapse zone can be avoided during belting, so that as the working face continues to advance, the drop of the top plate will not damage the water-repellent holes. Preferably, the distance between the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com