Method of arranging ultra-close seam mining surrounding-rock roadway

A roadway layout and extremely close-distance technology, which is applied in safety devices, ground mining, mining equipment, etc., to achieve the effects of improving safety, significant economic benefits, and ensuring production connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific examples.

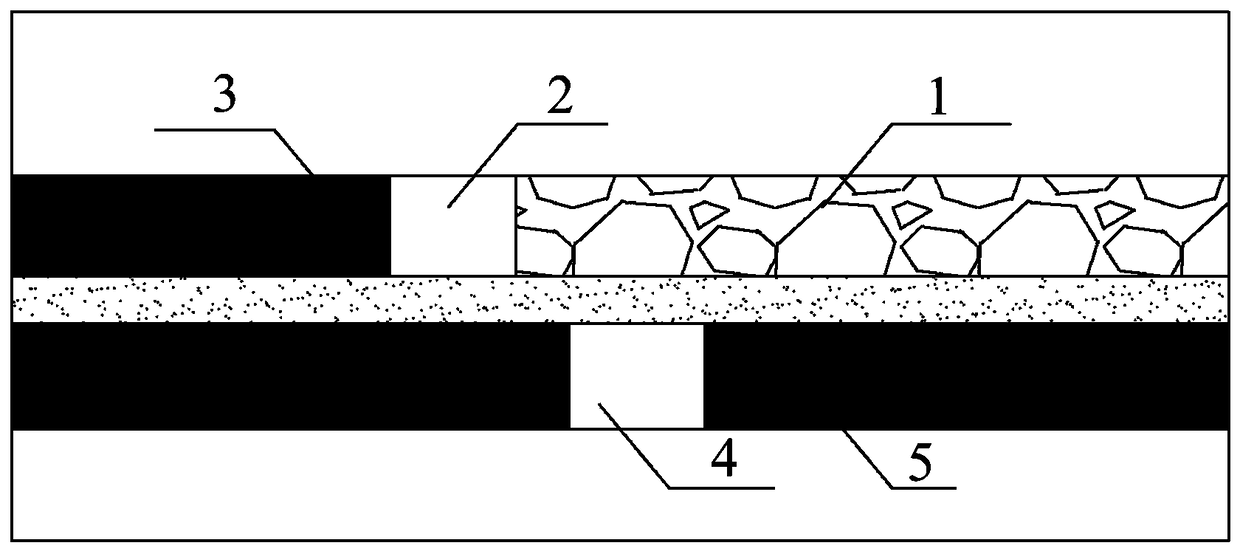

[0031] A surrounding rock roadway layout method for extremely close-distance coal seam mining, which is divided into three roadway layout methods according to the relative position of the lower coal seam roadway and the goaf in the upper mining area, including the staggered roadway layout method, overlapping roadway layout method and Layout of internal staggered roadway:

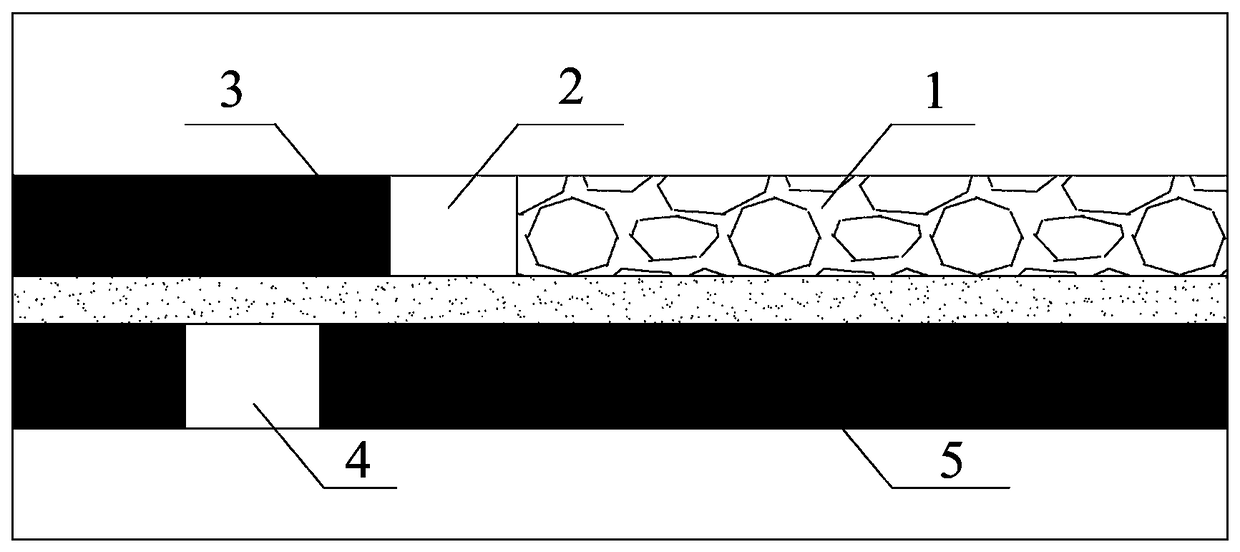

[0032] (1) Layout of staggered roadway:

[0033] According to the position of the goaf in the upper mining area, the side next to the gob is the upper coal roadway, and the lower coal roadway is arranged outside the upper coal roadway, that is, the lower coal roadway is located outside the lower layer of the goaf and below the upper coal pillar;

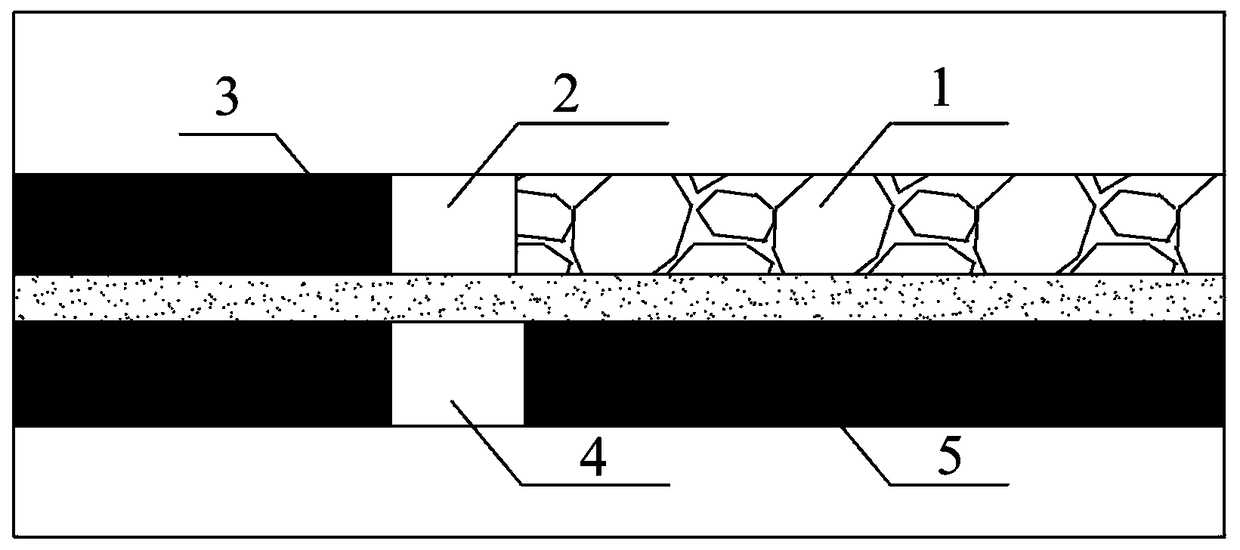

[0034] (2) Overlapping roadway layout:

[0035] The lower seam coal roadway and the upper seam coal roadway are overlapped on the plane, and the length of the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com