Gas testing method and device for worked-out section of stope of coal mines

A technology of gas detection and goaf, applied in mining equipment, measuring equipment, measurement, etc., can solve the problems of inability to use gas composition collection, gas dynamic analysis, etc., and achieve the effect of simple structure, less maintenance personnel, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

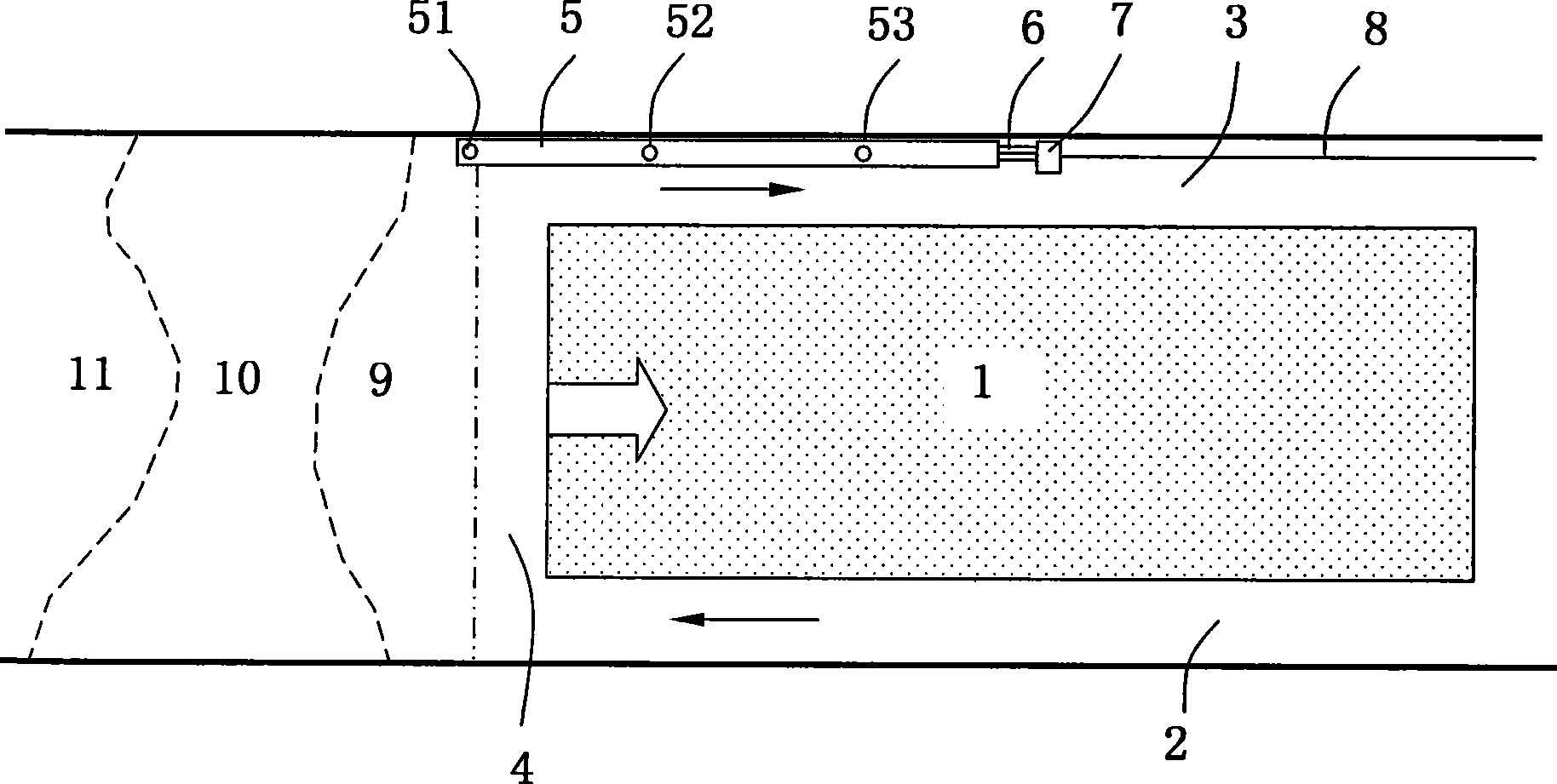

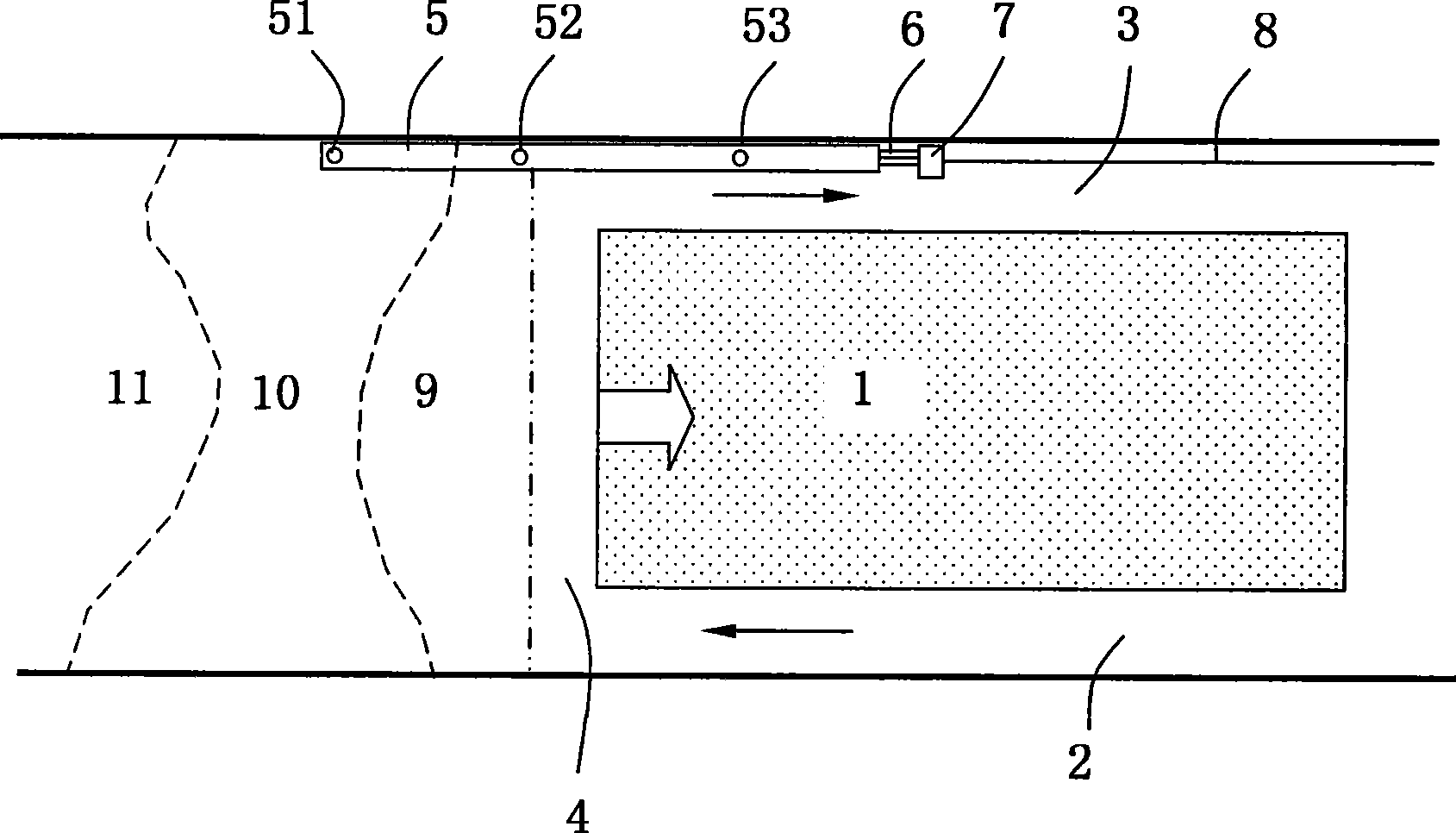

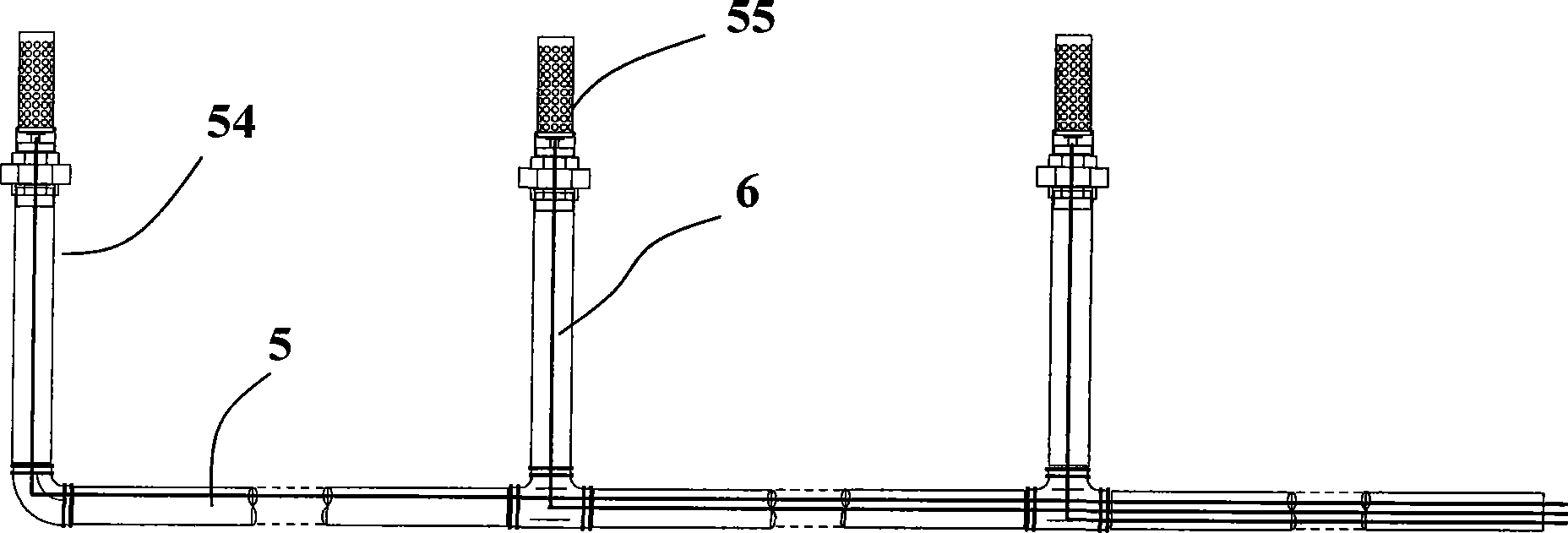

[0019] like figure 1 As shown: the two sides of the coal seam 1 are provided with an air inlet chute 2 and an air return chute 3, and the workers carry out production operations in the working face area 4. The hard protective pipe 5 is a galvanized water pipe about 150 meters long, and is laid in the wind return trough 3 . There are three detection through-holes 51, 52, 53 drilled on the hard protection tube. The first detection hole 51 is located at the end of the hard protection tube 5. The distance between adjacent detection through-holes is 50 meters, which is slightly larger than that of the coal seam. The farthest distance between the spontaneously combustible area and the working surface. Three soft collection pipes 6 are inserted into the hard protection pipe 5, and they pass through three detection through holes respectively, and each collection pipe is responsible for collecting the gas sample of one measuring point. The three collection pipes 6 can be selectively ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com