Stoping working face supporting-relief combined gob-side entry retaining roadway and construction method

A technology for mining working face and construction method, applied in tunnels, tunnel linings, mining equipment, etc., can solve the problems of long action time, high mining stress, difficult control of roadway surrounding rock, etc., and achieves overall strength and rigidity. High safety, fast and efficient support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

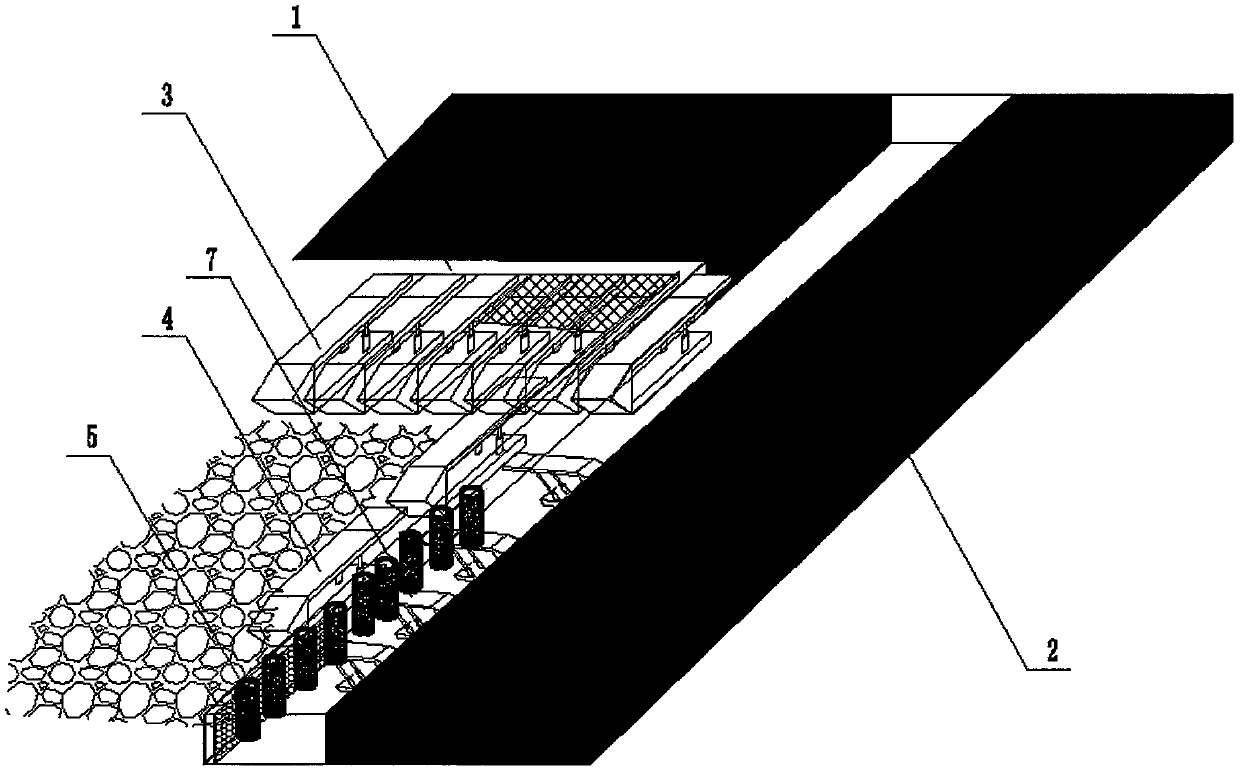

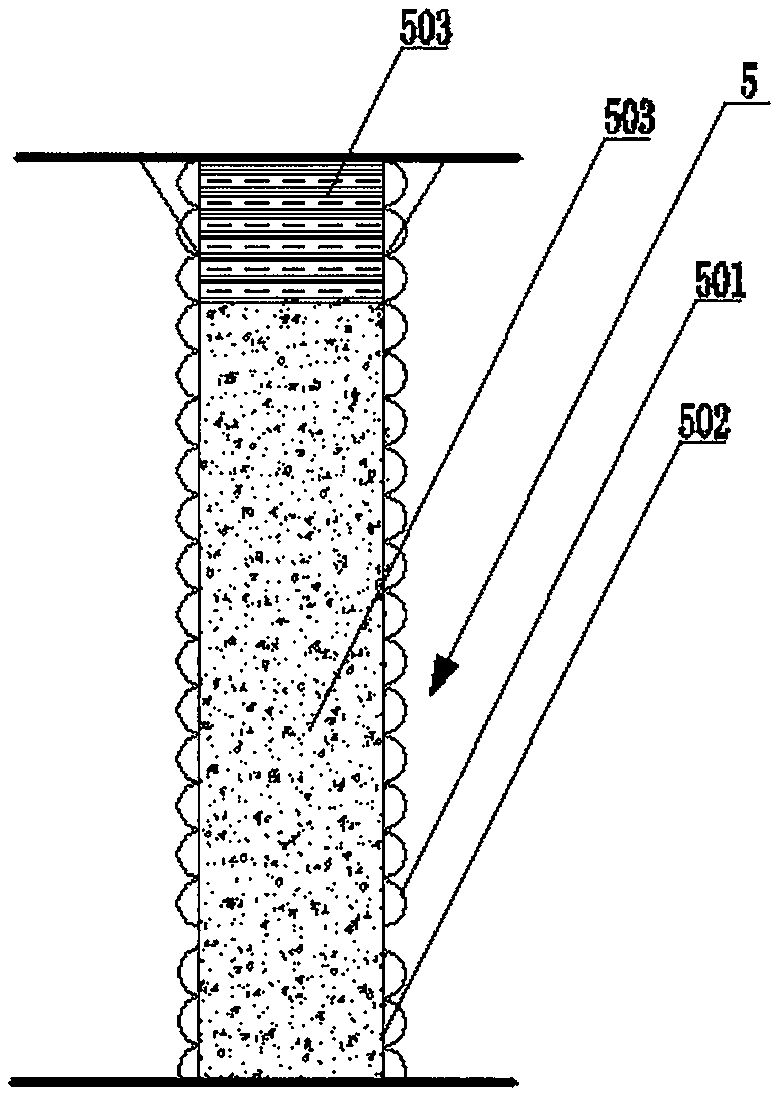

[0042] The "branch-unloading" combination gob-side entry roadway of the mining face is arranged between the goaf of the mining face 1 and the adjacent working face 2, on the side adjacent to the gob, on the side of the mining face 1 Behind the end support 3, close to the side of the goaf, along the direction of the roadway, there is a gangue-retaining hydraulic support 4 arranged close to the end support 3. A pier column 5 is arranged on the inside of the roadway, and the pier column 5 is firstly filled with concrete to a certain height, and then filled with a high-water material to ensure a crimped roof;

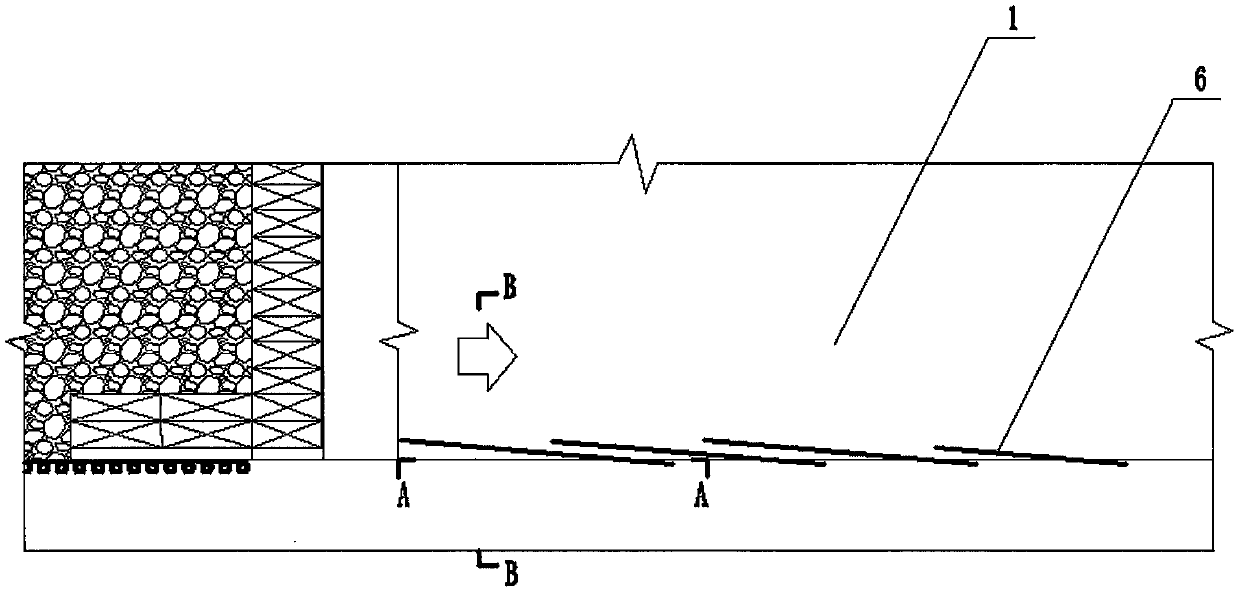

[0043] In the mining-affected area of the advanced mining face 1 or the lagging gob-side entry roadway area, hydraulic pressure relief drillings 6 are arranged from the roadway to the roof.

[0044]In this embodiment, behind the end support 3, in the area where the pier column 5 is to be arranged, there is also a unit support 7, which is close to the side of the goaf.

...

Embodiment 2

[0057] This implementation is different from Embodiment 1 except that the following parts are different, and the rest are the same:

[0058] In this embodiment, a flexible bag mold 10 is fixed between the piers 5, and the flexible bag mold uses polymer foam filling material to form a continuous goaf isolation and closure wall with the piers 5.

[0059] The construction method of the present embodiment comprises the steps:

[0060] (a) According to the size requirements of the gob-side retaining roadway, determine the roadway excavation section of mining face 1 and the support method and parameters in the roadway;

[0061] (b) Hydraulic fracturing is used to relieve pressure on the roof in the mining-influenced area of the advanced working face or in the lagging gob-side retaining roadway. The hydraulic fracturing drilling layout, parameters and construction technology are determined according to the lithology and structure of the roof ;

[0062] (c) During the recovery of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com