Medium-length hole shrinkage stoping method

A mining method and mining method technology, which is applied in ground mining, underground mining, special mining, etc., can solve the problems of large mining and cutting engineering, high mining cost, and low production efficiency, and achieve the reduction of mining and cutting engineering and reduce production costs. The effect of low and high drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

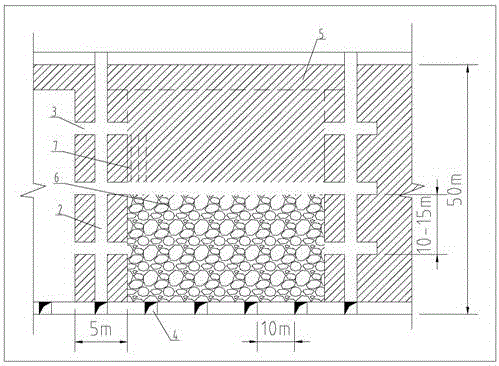

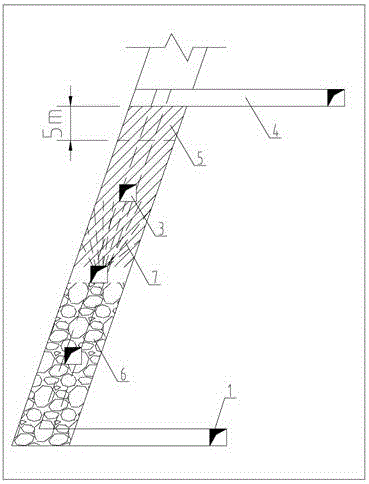

[0014] The specific implementation process of the deep hole ore retention mining method of the present invention is as follows, and for specific implementation methods please refer to figure 1 and figure 2 .

[0015] (1) First divide the ore body into a mine room every 50m, the end of the mine room is 5m as a column, and a 5m high column is reserved at the top;

[0016] (2) In the ore exit connecting road, excavate the ore body every 10m to reach the ore body, and then use shallow hole rock drilling and blasting along the full thickness of the ore body to form the bottom of the ore body in the ore exit road, and pull the bottom The height can meet the rock drilling requirements of the YGZ90 rock drill; excavate a pedestrian ventilation patio in the inter-column at the end of the mine house, and then excavate a segmented connecting road every 10-15m (the height of the segmented rock drilling) in the patio as a segmented rock drilling The channel through which personnel, equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com