Comprehensive underground test method for deformation and damage of terranes of mining top plate and mining bottom plate of coal bed

A technology of comprehensive testing, roof and floor, applied in the field of mine geophysical exploration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

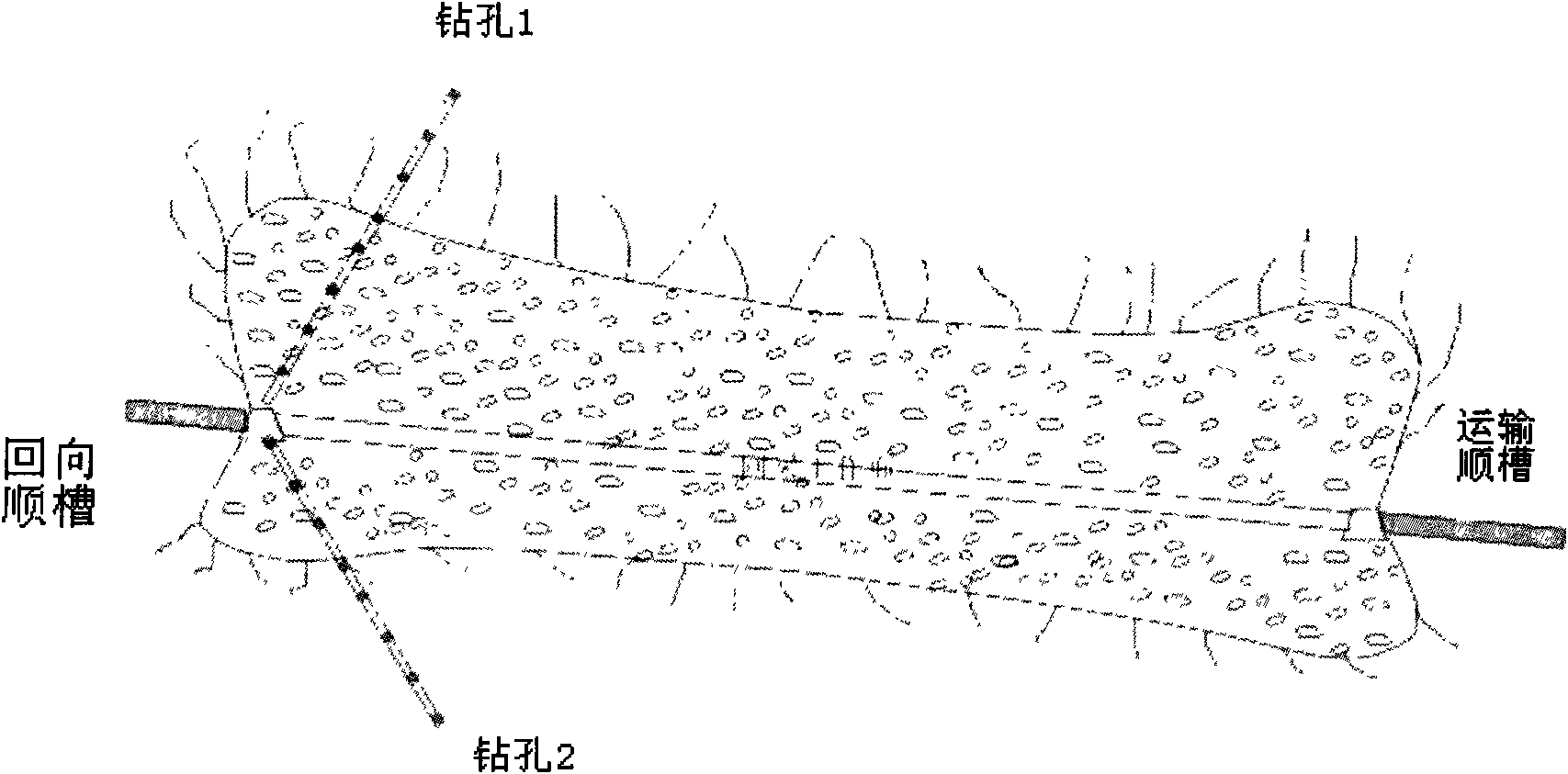

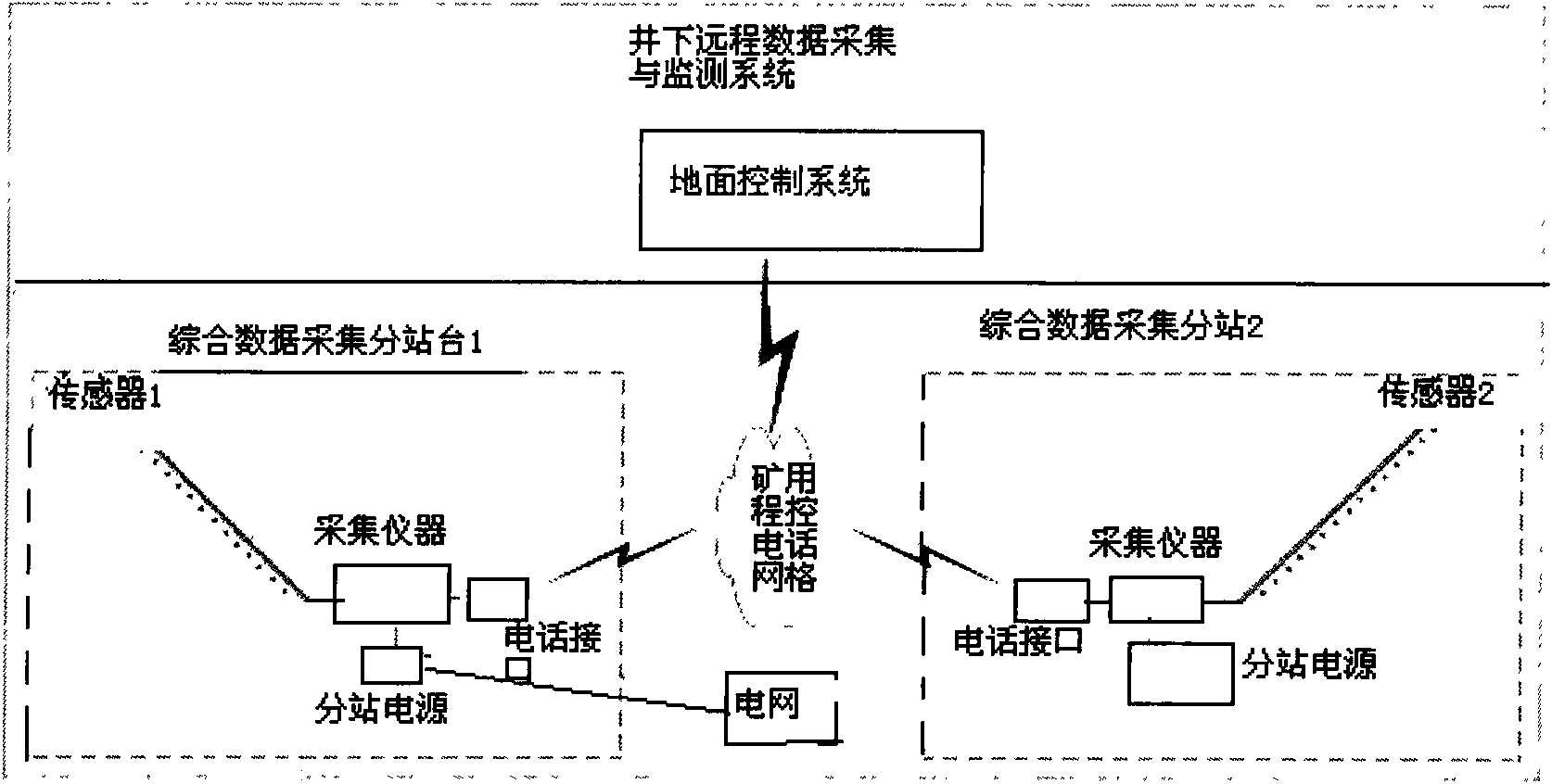

[0022] In combination with the technical characteristics of the present invention, the specific implementation of the comprehensive testing system for the deformation and damage of the top and bottom plates is as follows:

[0023] (1) Before the mining of the working face, a monitoring drilling site is arranged in the roadway. In the monitoring drilling site, an upward hole is arranged towards the roof, and a downward hole is arranged towards the bottom plate. The angle and depth of the upward and downward holes are determined according to the working face Depending on the geological conditions, the principle of setting the two holes is that the roof upward hole must pass through the expected water-conducting fracture zone, that is, exceed the empirical value of the maximum development height of the fracture zone; the floor downward hole must pass through the floor failure zone, that is, exceed the maximum damage depth of experience;

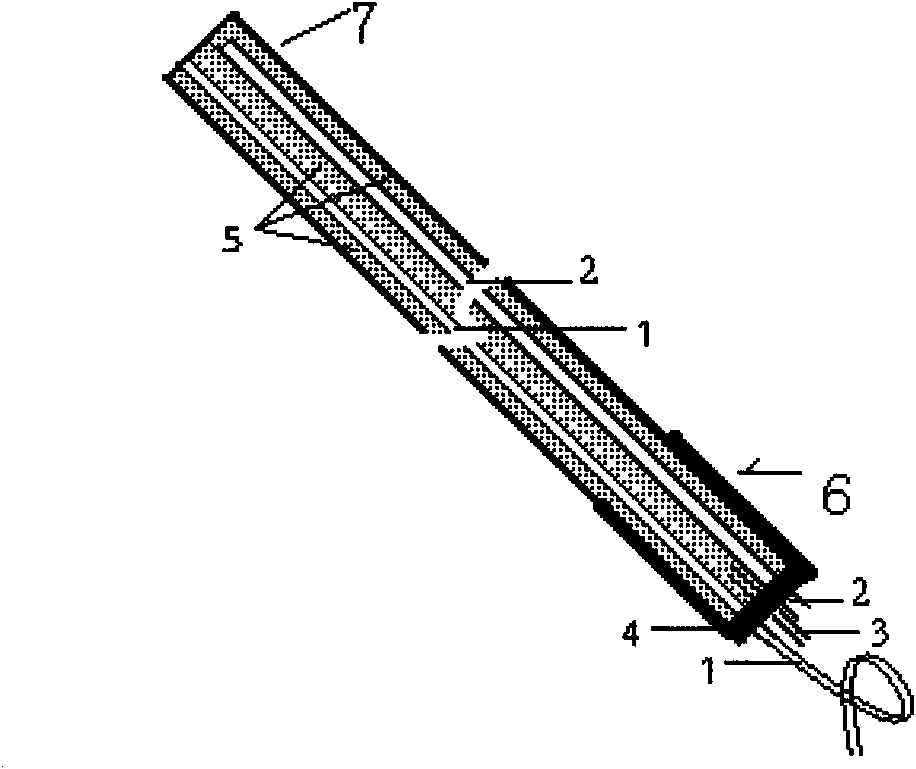

[0024] (2) Arrange detection electrodes, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com