Flat-bottomed pillar sublevel caving method of reinforced concrete structure artificial roof

A segmented caving method and artificial false roof technology, which is applied in ground mining, mining equipment, earth square drilling, etc., can solve the problems of lack of research on waste rock funnel control, improve ore recovery rate, reduce ore dilution, and solve The effect of loss impoverishment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

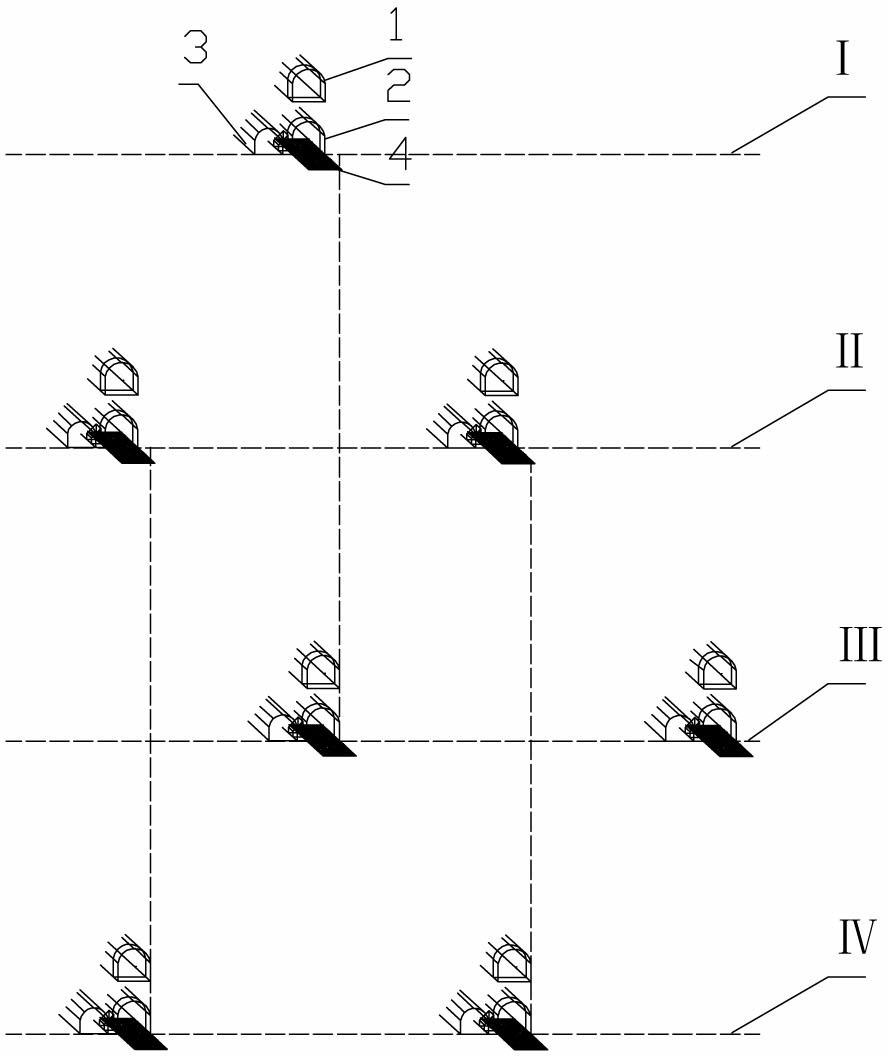

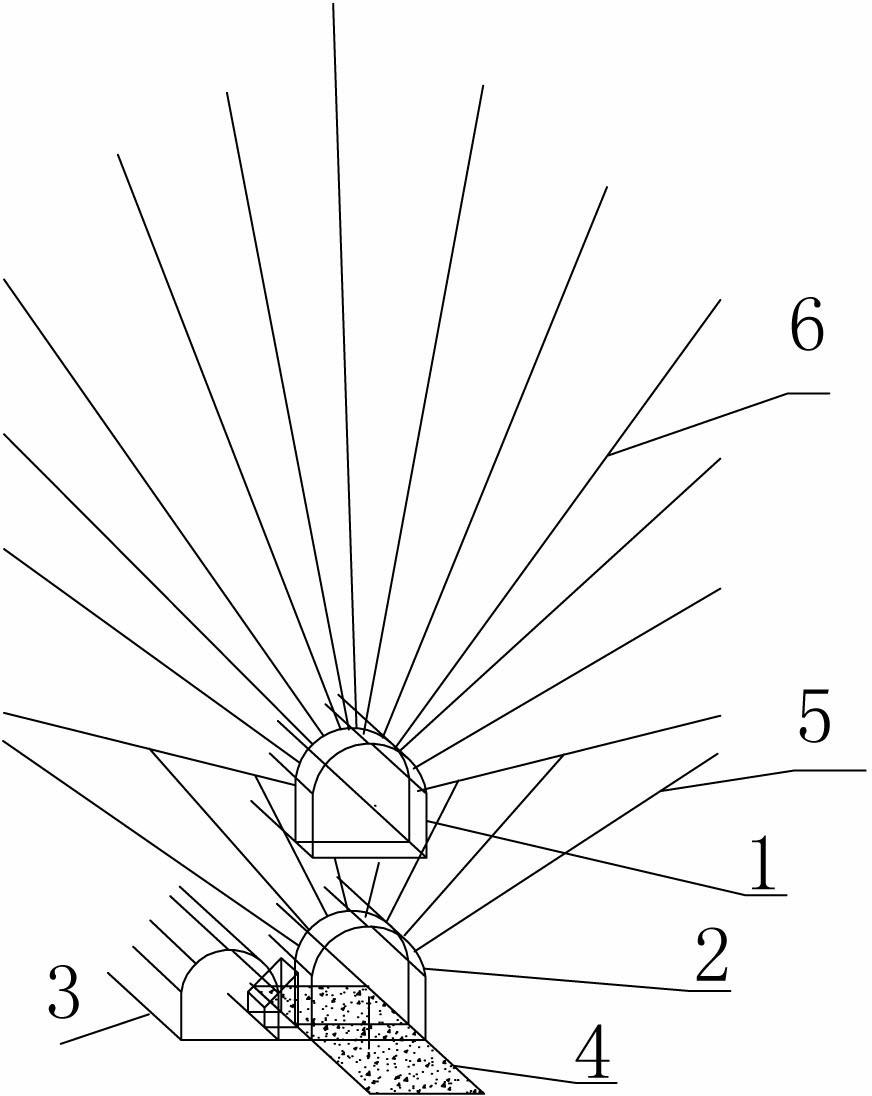

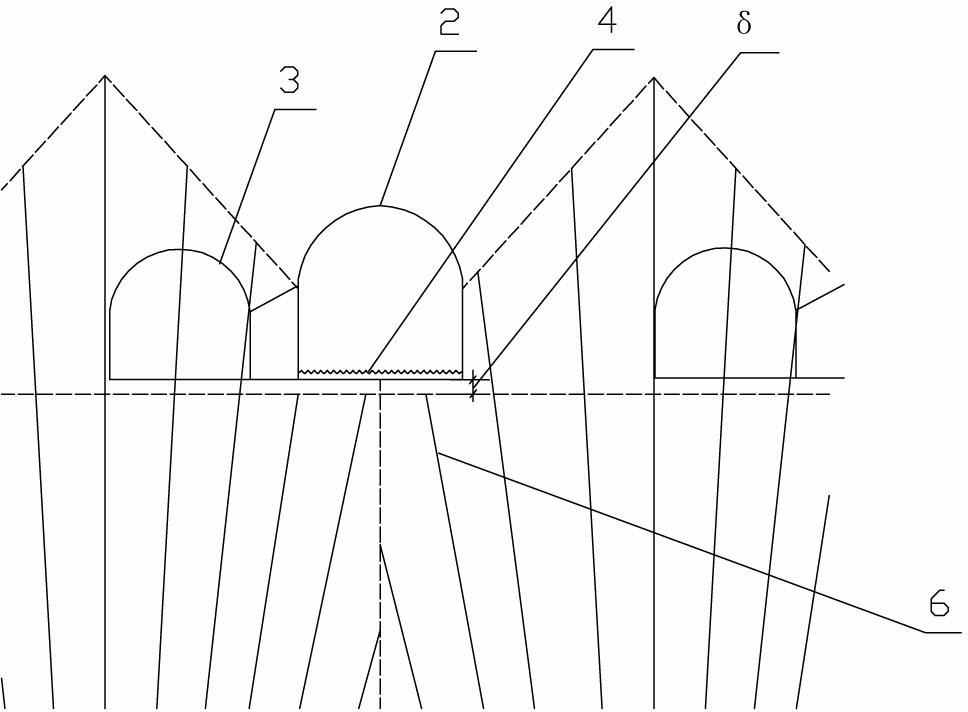

[0029] like figure 1 , figure 2 As shown, the flat-bottomed structure of the artificial false roof with steel-concrete structure of the present invention has the segmental caving method of the bottom column, including segmental mining under the cover rock stratum, the upper and lower segmental mining approaches are rhombus-shaped and staggered, and the mining approach is arranged with chisel The rock roadway 1 and the bottom structure adopt electric rake to extract the ore. The electric rake out ore bottom structure is composed of the ore-receiving roadway 2 and the electric rake roadway 3. The retreating mining is carried out from the end of the mining approach, and the rock-drilling roadway 1 and the receiving In the mine roadway 2, the pre-concentrated rock drilling method is adopted to arrange the upward fan-shaped medium-dee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com