Presplitting type wall cutting and filling stoping method for thin ore vein

A backfill mining method, a technology of thin ore veins, applied in the fields of backfill, surface mining, mining equipment, etc., can solve the problems of increasing crushing cost and lifting pressure, increasing tailings discharge pressure, worsening beneficiation process indicators, etc., to reduce tailings. The effect of stacking pressure, reducing crushing and improving beneficiation process indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

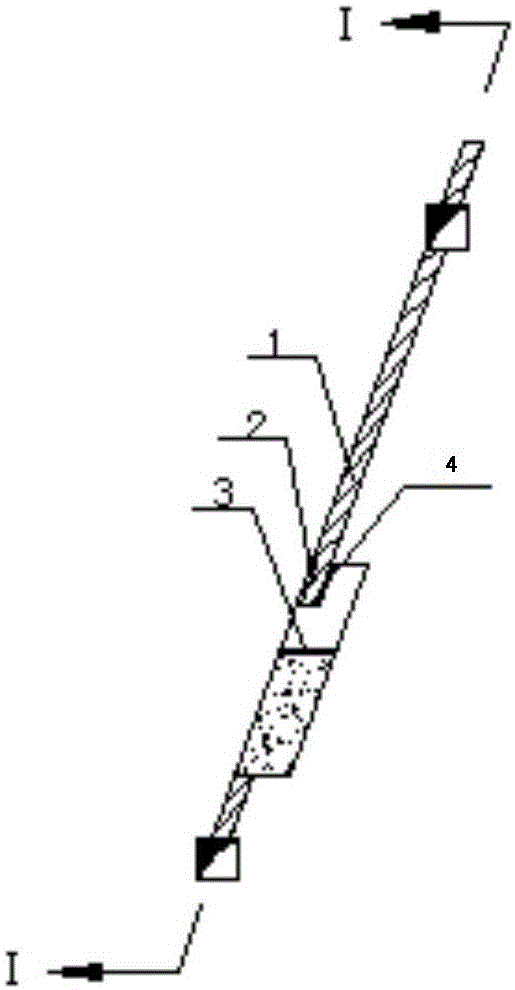

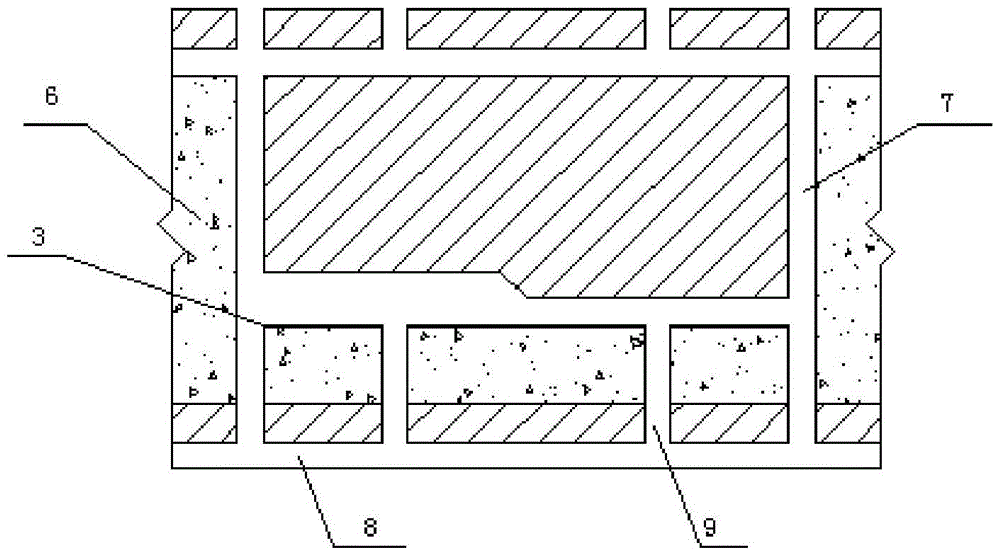

[0023] see figure 1 , image 3 with Figure 4 , first use the pre-splitting blasting technology to collapse the surrounding rock and fill it on the spot, and then collapse the ore body (vein)

[0024] After the bottoming of the ore block is completed, the surrounding rock is firstly collapsed (according to the stability of the surrounding rock, the surrounding rock of the upper wall can be collapsed, and the surrounding rock of the lower wall can also be collapsed). Construct pre-splitting holes along the ore-rock interface according to the requirements of pre-splitting blasting. The distance between the pre-splitting holes is 8 to 12 times the diameter of the blast hole, and there is no charge or less charge. The thickness of the collapsed surrounding rock is determined according to the minimum working face space requirements of the ore block (stope), and the blasting parameters of the surrounding rock are designed according to the normal stope blasting. The pre-splitting...

Embodiment 2

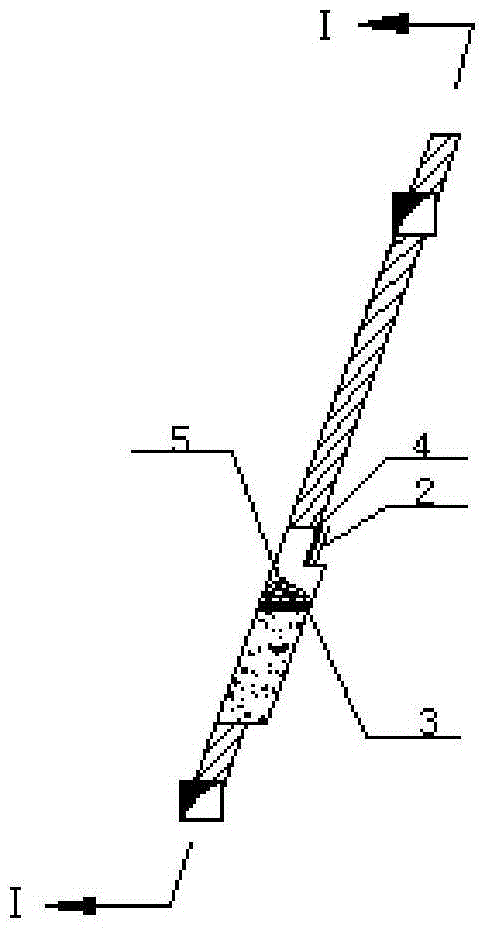

[0027] see figure 2 , image 3 with Figure 5 , first use the pre-splitting blasting technology to caving the ore body (vein), after the ore is out, then caving the surrounding rock and filling it on the spot

[0028] If the thickness of the ore body (vein) exceeds 0.8 to 1m, the ore body (vein) can also be collapsed first after the work of pulling the bottom of the ore block is completed. Construct pre-splitting holes along the ore-rock interface according to the requirements of pre-splitting blasting. The distance between the pre-splitting holes is 8 to 12 times the diameter of the blast hole, and there is no charge or less charge. The blasting parameters of the ore body (vein) are designed according to the normal stope blasting. The pre-splitting hole is detonated at the same time as the caving hole (main blast hole) of the ore body (vein), and the pre-splitting hole is detonated before the main blast hole to form a pre-crack, which reduces the impact of the detonation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com