Method for producing wet-process phosphoric acid by utilizing high-grade phosphate rock

A wet-process phosphoric acid, high-grade technology, applied in the field of phosphorus chemical industry, can solve the problems of low reaction activity, high viscosity of reaction slurry, no industrialization, etc., to improve the reaction rate and conversion rate of acidolysis, improve the reaction rate and conversion rate, The effect of complete acid hydrolysis reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

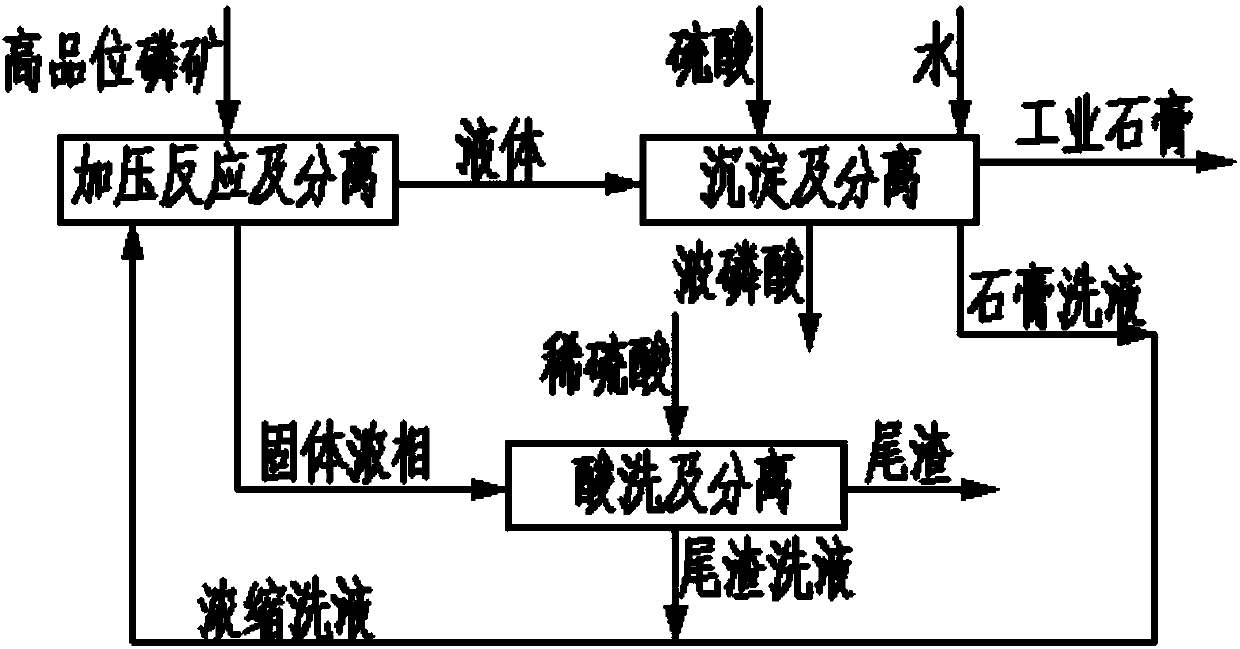

Method used

Image

Examples

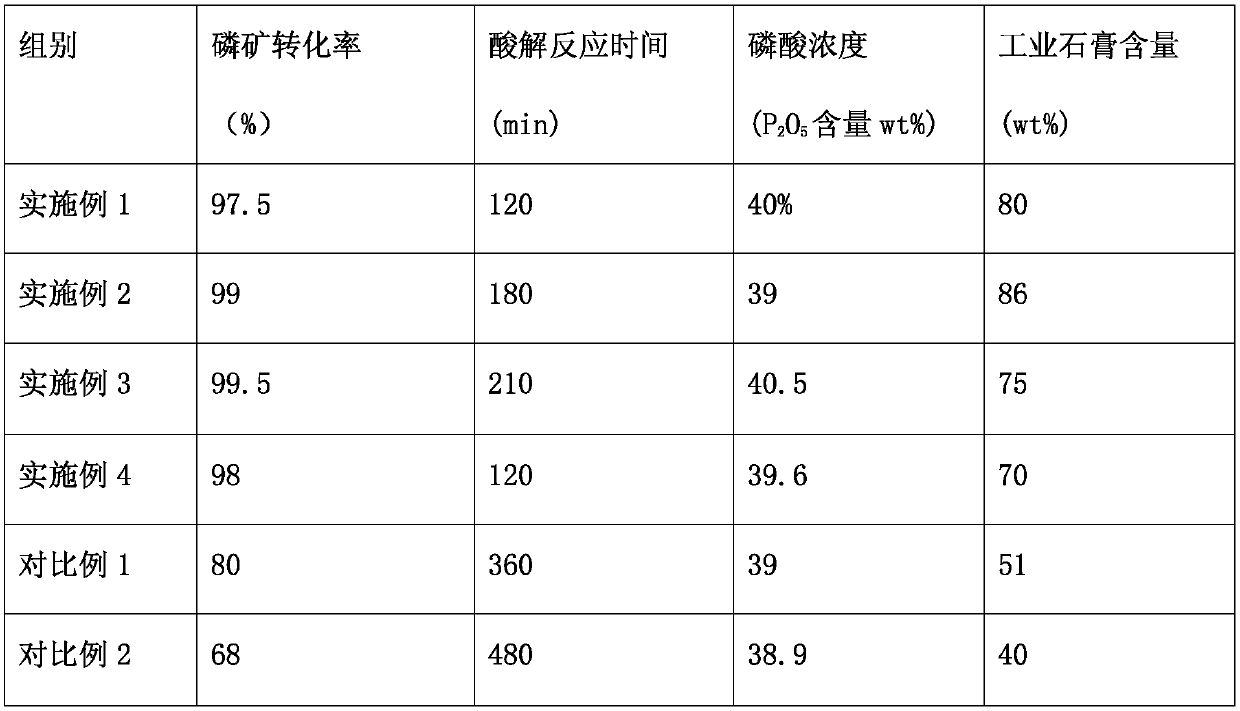

Embodiment 1

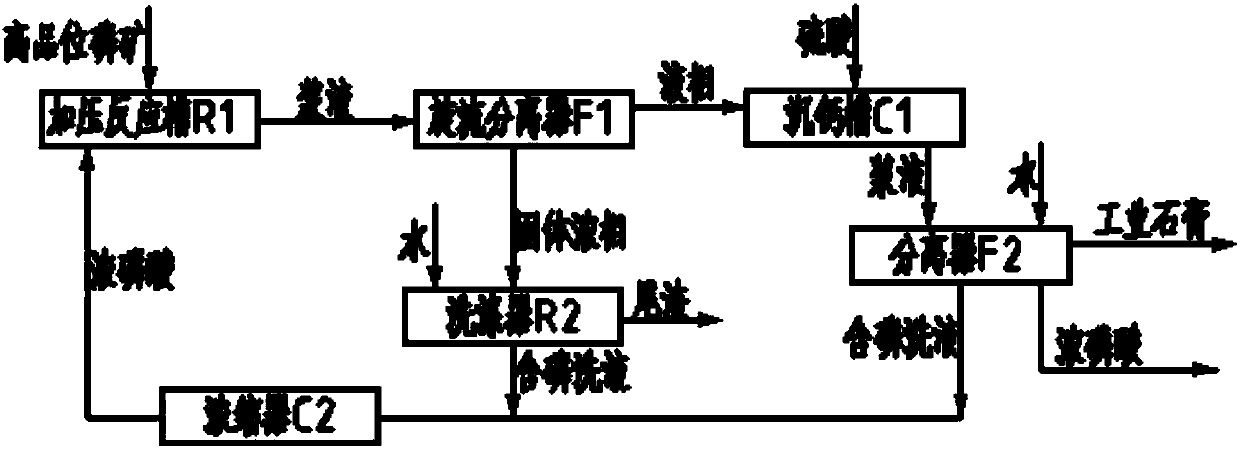

[0027] The technological process of this embodiment is as attached figure 2 shown. P of a phosphate rock 2 o 5 The grade is 31wt%, the MgO content in the phosphate rock is 0.5wt%, and the Al in the phosphate rock 2 o 3 +Fe 2 o 3 The sum of the contents is 1wt%. The phosphate rock is ground into pulp, and the water in the pulp is centrifugally separated to 16wt% by a decanter centrifuge. P 2 o 5 The 95°C phosphoric acid with a content of 37wt% and the phosphate rock slurry with a moisture content of 16wt% are subjected to acidolysis reaction in the pressurized reaction tank R1, and 1000 parts of dry base phosphate rock are added. The operating conditions of the acidolysis reaction are: the temperature is 117°C, The reaction pressure is 0.3 MPa, and the reaction time is 2 hours. The reacted acidolysis slurry enters the separator F1 for solid-liquid separation, and the obtained solid slag is washed in the scrubber R2 to obtain 1000 parts of phosphorus-containing washing...

Embodiment 2

[0029] The technological process of this embodiment is as attached figure 2 shown. P of a phosphate rock 2 o 5 The grade is 36wt%, the MgO content in the phosphate rock is 0.4wt%, and the Al in the phosphate rock 2 o 3 and Fe 2 o 3 The total content of the phosphate rock is 0.9wt%. The phosphate rock is ground into a slurry, and the water content of the slurry is centrifugally separated to 12% by a decanter centrifuge. P 2 o 5 37wt% phosphoric acid at 90°C and phosphate rock slurry containing 16wt% water are subjected to acidolysis reaction in pressurized reaction tank R1, and 1000 parts of dry base phosphate rock are added. The operating conditions of acidolysis reaction are: the temperature is 105°C, and the reaction The pressure is 0.2 MPa, and the reaction time is 3 hours. The reacted acidolysis slurry enters the separator F1 for solid-liquid separation, and the obtained slag is washed in the scrubber R2 to obtain 1000 parts of phosphorus-containing washing water...

Embodiment 3

[0031] The technological process of this embodiment is as attached figure 2 shown. P of a phosphate rock2 o 5 The grade is 33%, the MgO content in the phosphate rock is 0.6wt%, and the Al in the phosphate rock 2 o 3 +Fe 2 o 3 The sum of the contents is 1wt%. The phosphate rock is ground into pulp, and the water in the pulp is centrifugally separated to 2wt% by a decanter centrifuge. P 2 o 5 37wt% phosphoric acid at 95°C and phosphate rock slurry containing 2wt% water are subjected to acidolysis reaction in pressurized reaction tank R1, and 1000 parts of dry base phosphate rock are added. The operating conditions of acidolysis reaction are: the temperature is 140°C, and the reaction The pressure is 0.3MPa, and the reaction time is 5 hours. The reacted acidolysis slurry enters the separator F1 for solid-liquid separation, and the obtained slag is washed in the scrubber R2 to obtain 1000 parts of phosphorus-containing washing water, wherein P 2 o 5 The content is 100 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com