Mining method with residual ore recovery function

A mining method and residual ore technology, applied in the field of residual ore recovery mining method, can solve the problems of large surface impact, low safety, low production efficiency, etc., and achieve the effects of saving costs, improving safety, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

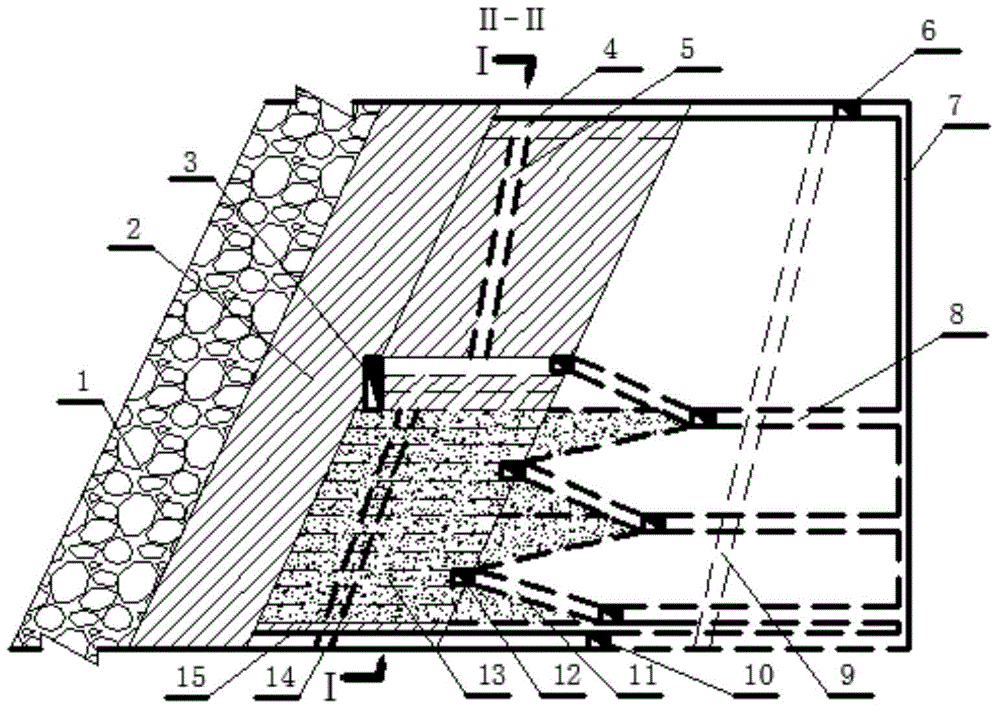

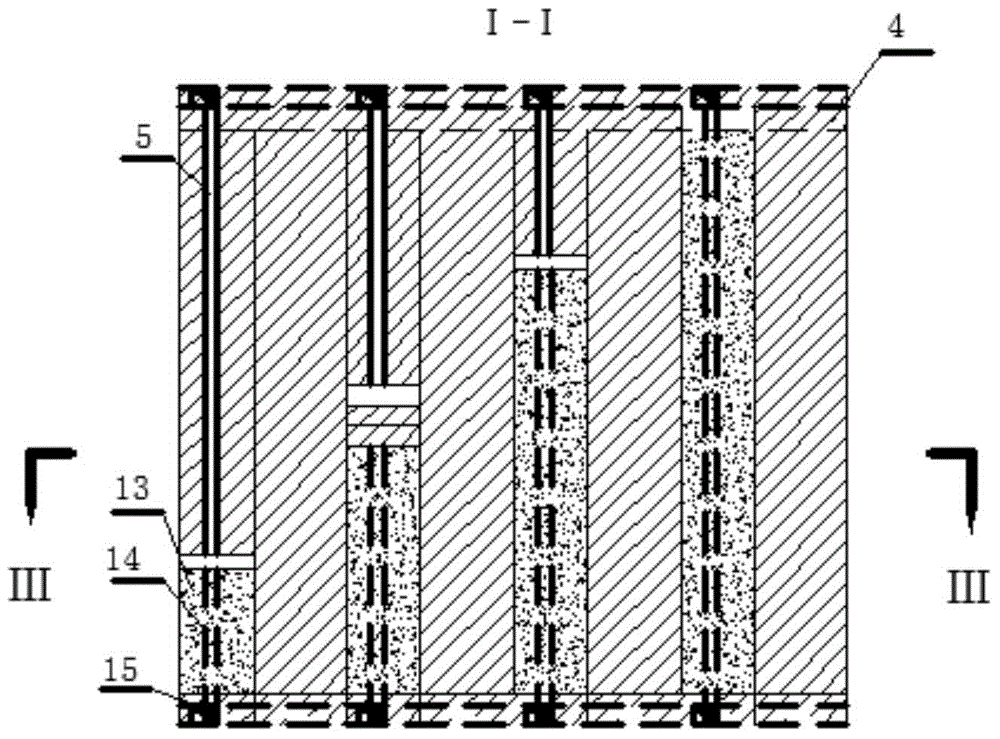

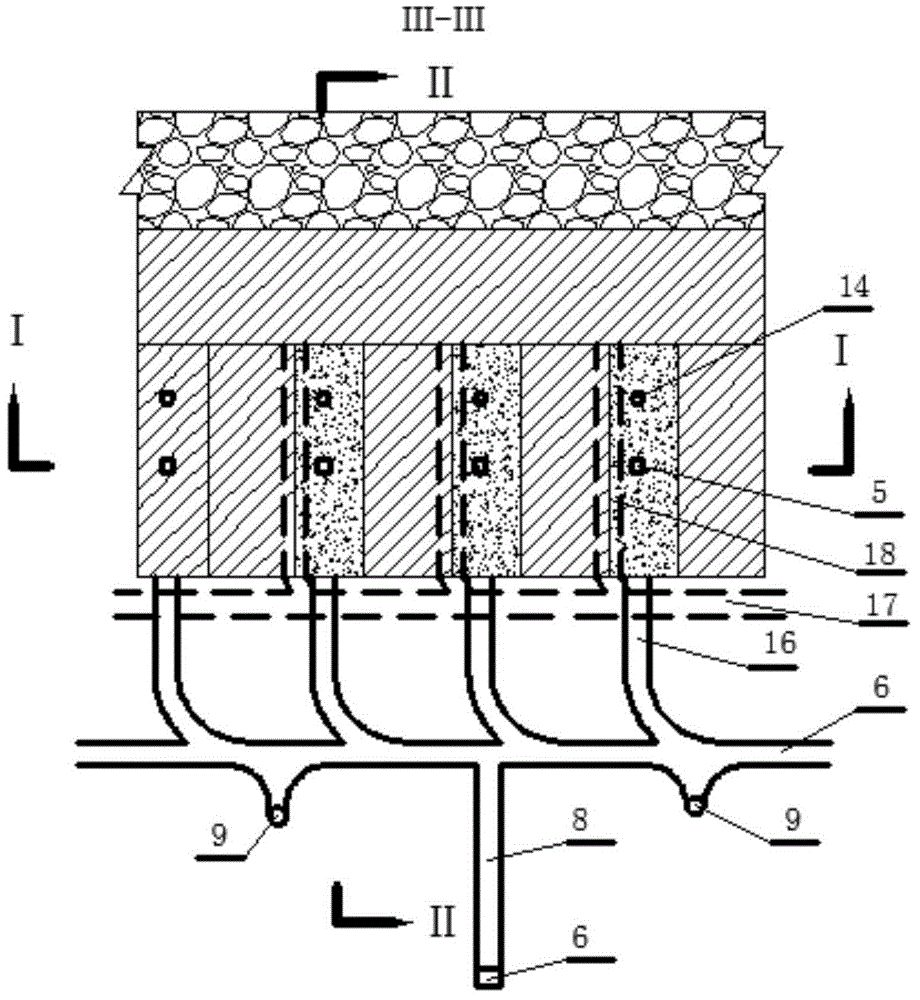

[0021] The embodiment of the present invention provides a mining method for ore recovery, which solves the technical problems of low safety, low recovery rate, and low efficiency in the prior art of residual ore recovery, and achieves the improvement of residual ore recovery safety, recovery rate and recovery. efficiency effect.

[0022] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

[0023] A residual ore recovery mining method, comprising:

[0024] Retain security pillars with a thickness of 5-15m in the hanging wall of the residual ore;

[0025] The ore body is divided into continuous mining units, and the next mining unit is mined after the mining and filling are completed;

[0026] Wherein, the mining unit comprises three continuous ore layers, i.e. an upper stratum, an intermediate stratum and a lower stratum; the upper stratum is preferentially mined, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com