Real-time monitoring and prewarning system and method for damage depth of coal seam floor of stope face

A technology for mining working face and coal seam floor, applied in mining equipment, mining equipment, earthwork drilling and other directions, can solve the problems of inability to carry out continuous observation, difficult to achieve continuous dynamic monitoring, etc., to improve work efficiency, save manpower and material resources, improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

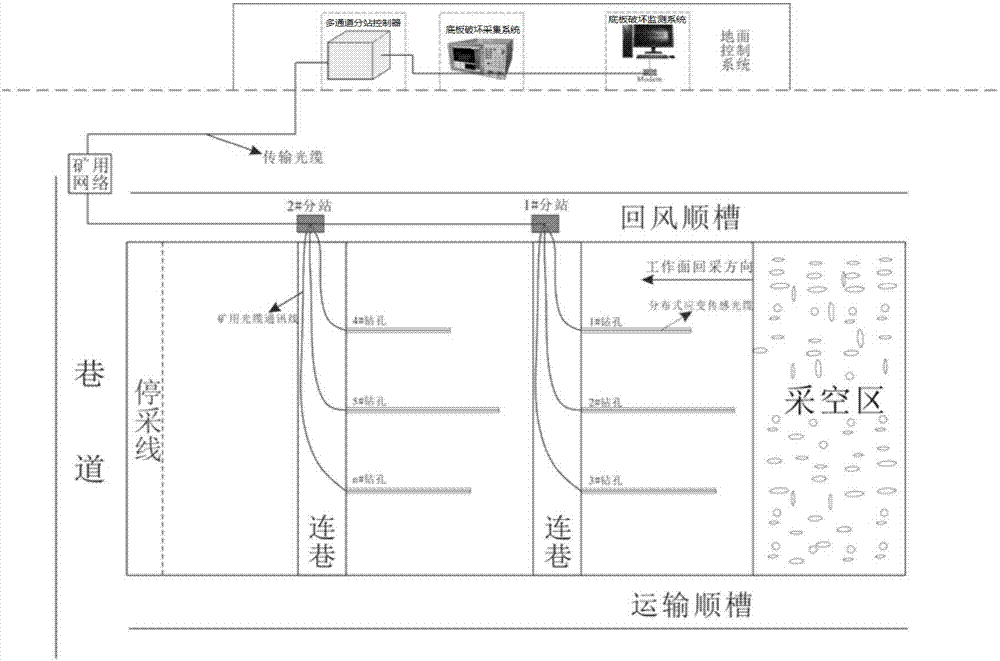

[0030] Such as figure 1 As shown, a real-time monitoring and early warning system for the damage depth of the coal seam floor in the mining face, which includes:

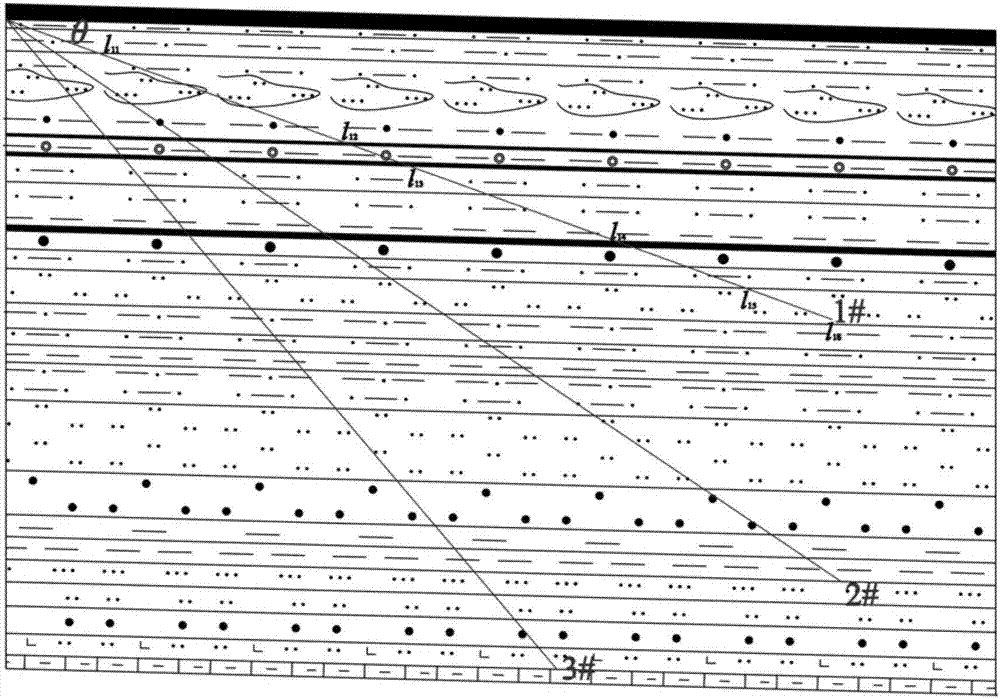

[0031] Bottom plate drilling optical cable test system: select a suitable area in the roadway for the working face to implement bottom plate drilling, and the drilling design parameters meet the following two requirements: (1) The drilling should face the direction of the cutting hole and be parallel to the mining direction; (2) The drilling control depth should be greater than the theoretically calculated floor damage depth, and the theoretical depth is calculated by formula (1):

[0032] h=0.0085H+0.1665α+0.1079L-4.3579 (1),

[0033] In formula (1), H is the mining height of the coal seam, L is the oblique length of the working face, and α is the inclination angle of the coal seam.

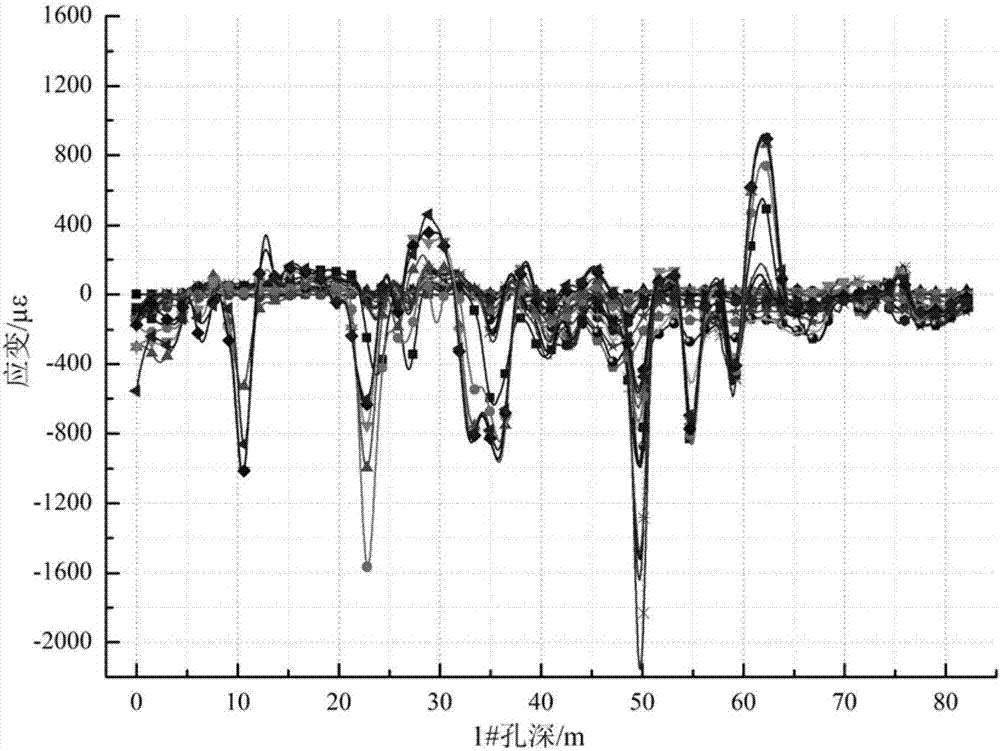

[0034]After the drilling construction is completed, the distributed strain sensing optical cable is installed. After the distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com