Method and device for obtaining CO2 from oil production well outlet in carbon dioxide oil recovery method

A technology for carbon dioxide and oil production wells, applied in chemical instruments and methods, separation methods, inorganic chemistry, etc., can solve problems affecting the utilization process of methane and other gases, hydrogen sulfide corrosion equipment and pipelines, environmental pollution, etc., to achieve easy toxicity, Ensure safe mining and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment relates to a preparation method of an additive, and the preparation method comprises the following steps:

[0055] S1: Dissolve N-hydroxyethyl-N-methylbenzylamine, p-carboxystyrene acid and 2-acetamidoacrylic acid at a weight ratio of (10-30):(3-8):1 in the solvent, and stir Evenly, add concentrated sulfuric acid, heat up to 80-150°C, and react for 2-5 hours to obtain an intermediate solution;

[0056] S2: Lower the temperature of the intermediate solution to 40-120°C, add N,N-methylenebisacrylamide and catalyst to the intermediate solution and polymerize for at least 8 hours under nitrogen, and obtain the additive after purification and drying, where N, The weight ratio of N-methylenebisacrylamide to N-hydroxyethyl-N-methylbenzylamine is (2-10):(5-20).

[0057] Preferably, step S2, adding nano-montmorillonite to the intermediate solution, stirring at 80-150°C for more than 1 hour, then adding N,N-methylenebisacrylamide, catalyst and silica sol, stirrin...

Embodiment 2

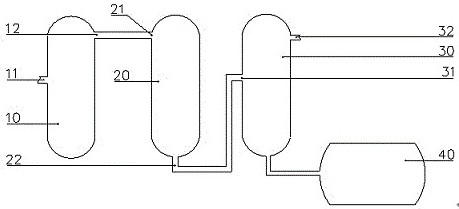

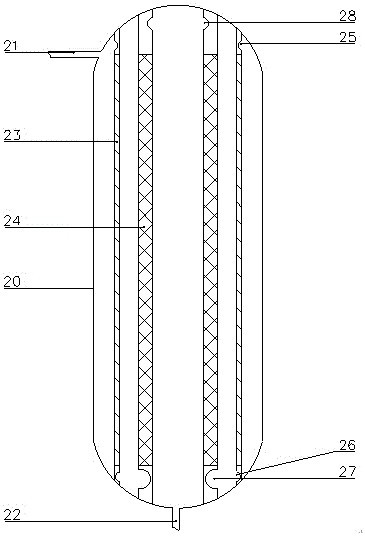

[0103] This embodiment relates to a device for obtaining carbon dioxide from the outlet of an oil well, the device comprising a first recovery tower 10, the first recovery tower 10 is provided with a first air inlet 11 and a first gas outlet 12, and the first recovery tower 10 is connected with The first compressor, and the first recovery tower 10 is externally connected with the first refrigeration mechanism; the second recovery tower 20, the second recovery tower 20 is provided with a second air inlet 21 and a second gas outlet 22, and in the second recovery tower 20 The impurity removal channel is set, and the impurity removal channel is used to place the additive; the third recovery tower 30, the third recovery tower 30 is provided with the third air inlet 31 and the third gas outlet 32, and the third recovery tower 30 is connected with the second compressor and Second refrigeration mechanism.

[0104] The associated gas passes through the first recovery tower 10, and the ...

Embodiment 3

[0108] This example relates to a method for obtaining carbon dioxide from the outlet of the oil production well. This example uses the additive 1# in Example 1 and the device in Example 2 to recover the associated gas obtained from the outlet of the oil production well. Oil wells use liquid carbon dioxide to drive oil, so the concentration of carbon dioxide in the associated gas is relatively high. The specific recovery methods are as follows:

[0109] (1) Collect associated gas from the outlet of the oil production well, lower the temperature of the associated gas to 10-20°C, and pressurize the associated gas to 2.5-4.0MPa, so as to conduct preliminary treatment of the associated gas to obtain the first treated gas;

[0110] (2) Contact the first treatment gas with additives to remove hydrogen sulfide in the first treatment gas, the removal temperature is 100°C to obtain the second treatment gas, and lower the temperature of the second treatment gas to 32-40°C , the pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com